CTP Plates offset Printing Plates Positive thermal plates

CTP Plates Offset Printing Plates: Unveiling Positive Thermal Plates’ Precision and Versatility

In the dynamic world of printing, precision and efficiency reign supreme. Among the essential tools driving modern offset printing is the Computer-to-Plate (CTP) technology, particularly Positive Thermal Plates, which are revolutionizing the manufacturing process with their unique functionality and wide application spectrum. But what makes these CTP plates standout, especially in terms of technical performance and end-use value? Let's explore this through a deeper lens into their functions and practical uses.

Positive Thermal CTP Plates: A Technological Perspective

At its core, a positive thermal plate used in offset printing is an aluminum-based printing plate coated with a heat-sensitive layer. Unlike conventional photopolymer plates referencing UV light exposure, thermal plates react to heat – typically a laser – enabling highly precise image inscription without traditional chemical processing.

Working with aluminium CTP (Computer-to-Plate) positive thermal plates daily reveals a fascinating interplay between chemistry, physics, and precision engineering. The seemingly simple process of exposing the plate to a laser to create the image masks a complex series of chemical reactions. Plate quality hinges not only on the laser's power and accuracy but also on factors like the ambient temperature and humidity in the processing room. Slight variations in these conditions can lead to inconsistencies in plate development, resulting in issues like scumming, pinholes, or uneven ink transfer during the offset printing process. Furthermore, optimizing the pre-press workflow, including the RIP settings and the type of imaging laser, is crucial for achieving the desired resolution and tonal range, directly impacting the final print quality and overall production efficiency.

One particularly insightful experience involved troubleshooting a recurring problem of image dropouts on a specific batch of plates. After exhaustive investigation, we discovered the issue stemmed not from the plates themselves, but from a subtle change in the factory's water supply's pH level, affecting the chemistry of the processing solutions. This highlighted the criticality of maintaining consistent environmental and processing parameters. This incident underscores the importance of proactive preventative maintenance, thorough quality control checks at each stage of the process, and a detailed of the interplay between the plate's chemical composition and the processing environment – a nuanced aspect that goes beyond simply following the manufacturer's instructions. It emphasizes a holistic approach that integrates meticulous process control with

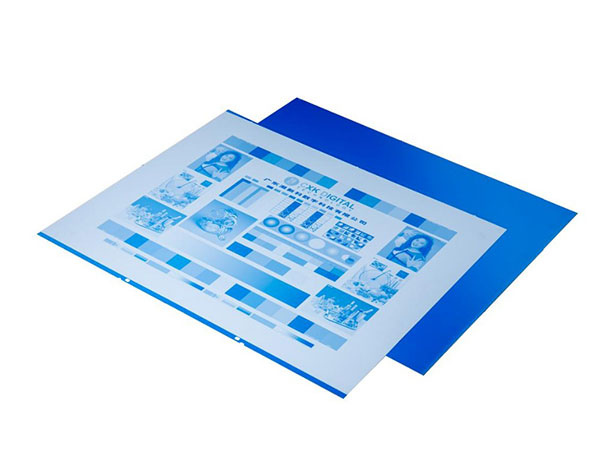

This thermally activated mechanism revolutionizes plate-making in the respect of environmental friendliness, durability, and reproduction clarity. By absorbing laser-generated heat, certain parts of the plate harden while unhardened sections are removed during the development process. The “positive” nature means the grained plate clearly exposes image areas after development, creating a distinct contrast which facilitates cleaner, sharper print results.

Critical Functional Benefits in Offset Printing

-

Enhanced Resolution & Detail: Due to the fine sensitivity of thermal technology, Positive Thermal CTP plates support high resolution images, translating into superior text sharpness and photo quality—critical for brand-accurate reproductions.

-

Solvent and Scratch Resistance: Aluminum, combined with thermal coating layers, affords excellent resistance against solvents or abrasive press chemicals used during printing runs, which extends plate life and reduces waste.

-

Waste Reduction and Eco-friendly Development: These plates typically employ chemistry-free, simple water or mild developer processing, vastly minimizing hazardous chemical use. Save costs, comply better with environmental regulations, and promote greener presses.

-

Rapid Turnaround & Consistency: Thermal plates facilitate tighter process control owing to their consistent and repeatable laser exposure sensitivity, ideal for high-volume commercial applications where deadlines are stringent.

Transformative Use Cases Across Industries

-

Commercial Publishing: With their high fidelity and affordability, Positive Thermal CTP plates are ideal for mass market books, magazines, and brochures needing durability across extensive print runs.

-

Packaging Engineers: Their ability to accurately render fine images and multiple colors complements packaging designs that batter exposure and mechanical demands on the plate surface, whether folding cartons or labels.

-

Advertising and Promotional Printing: Fast turnaround combined with premium print quality is aura in promotional collateral generation, such as flyers or posters, tuned to capture consumer attention at every step.

-

Security Printing: Due to the stability and precise image rendition, these thermal CTP plates are preferable in banknotes and counterfeit-proof materials where exact detail proves critical.

Distinctiveness in Contemporary Printing Workflows

Traditional wet-process photographic plate-making involved numerous repetitive workflows alongside materials potentially harmful to operators. Positive Thermal Plates integrate with fully digital systems eliminating many manual procedures, substantially reducing error margins and human intervention, paving the way towards Industry 4.0-compliant efficient print factories.

Their robustness under intense press conditions also significantly cuts unused plate disposal rates. Sharing attributes rooted deeply in physics—heat conduction, reflectivity efficacy, and coating chemistry—the success of positive thermal plates lies beyond mere image transfer. It stretches into sustainability embedded within printing infrastructures alongside stringent productivity demands.

https://www.al-alloy.com/a/ctp-plates-offset-printing-plates-positive-thermal-plates.html