Anti slip aluminum stair tread

When we talk about safety enhancements on stairs, “anti-slip aluminum stair tread” might ring a familiar bell as one of the most dependable solutions out there.

Why Aluminum for Anti-Slip Stair Treads?

Aluminum is a standout material due to several intrinsic qualities:

Lightweight but Strong: With a density of approximately 2.7 g/cm³, aluminum alloys provide structural integrity without excessive weight. The typical aluminum alloy used is 6061-T6 or 3003-H14, recognized for excellent formability and corrosion resistance.

Natural Corrosion Resistance: A thin oxide layer on its surface self-heals if scratched, which helps stair treads maintain safety features even in exterior or humid environments.

Recyclability: Aluminum is nearly 100% recyclable without losing its properties, making it a sustainable choice for manufacturers and consumers.

The Science Behind Anti-Slip Features

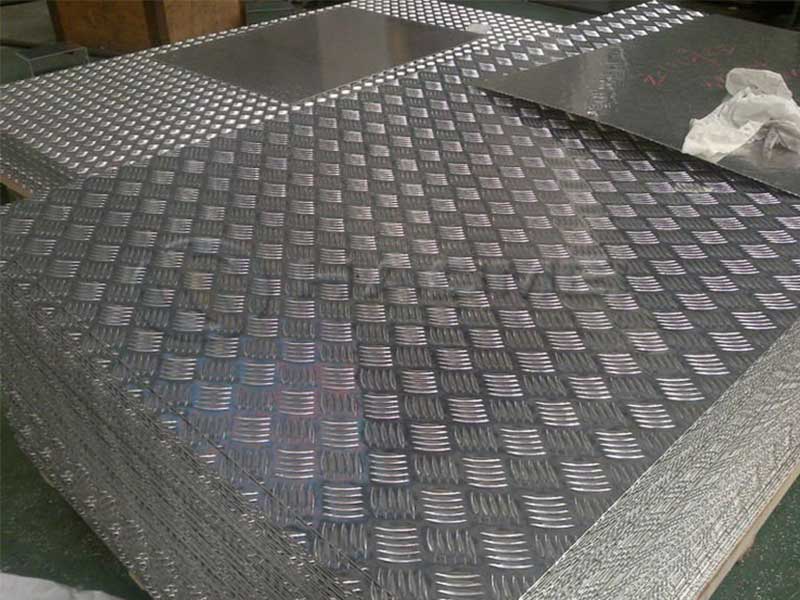

Anti-slip aluminum stair treads aren’t just raw metal panels debossed with random patterns—they use design and scientific calculation to optimize friction. Typical implementations include:

Mechanical Serration: Patterns like diamond-shaped or raised ridges increase surface grip by raising the effective coefficient of friction. For aluminum alloy 6061-T6 treads, these patterns are formed by stamping, bending, or extrusion.

Non-Slip Inserts: Sometimes, they integrate abrasive materials (such as aluminum oxide grit) into adhesive strips applied directly onto the tread, combining metallurgical strength with industrial-grade slipping resistance.

Surface Treatments: Anodizing, applied under standards such as ASTM B580, thickens the aluminum’s oxide layer and can add textured finishes that further discourage slippage.

Chemical and Physical Properties: Why They Matter for Anti-Slip Treads

| Property | Typical Value (6061-T6) | Significance to Stair Treads |

|---|---|---|

| Tensile Strength | ~290 MPa | Ensures tread can withstand weight and impact |

| Yield Strength | ~240 MPa | Resists permanent deformation under load |

| Elongation | ~12% | Maintains some flexibility to avoid cracking under stress |

| Density | 2.70 g/cm³ | Lightweight makes installation easier and safer |

| Thermal Conductivity | ~167 W/m·K | Resists heat damage, important in industrial settings |

| Corrosion Resistance | Excellent (due to oxide layer) | Ensures longevity in wet or corrosive environments |

Standards and Tempering Conditions

Anti-slip aluminum stair treads must meet certain industry standards to guarantee both safety and durability.

Implementation Standards: Many stair tread systems conform to OSHA requirements (29 CFR 1910.25 for walking surfaces) ensuring tread height, depth, and slip resistance.

Temper Designation: Alloys like 6061-T6 reflect a temper where the aluminum is solution heat-treated and artificially aged — balancing hardness with toughness.

Anodizing Standards: ASTM B580 covers the anodizing process ensuring consistent oxide coating thickness between 8 to 25 micrometers, enhancing durability and slip resistance.

Sustainability: An Often Overlooked Advantage

From production through end-of-life, aluminum anti-slip stair treads exemplify sustainability. Compared to other materials such as steel or rubber composites, aluminum uses less energy per unit strength and is infinitely recyclable. Remanufacturing stair treads from recycled aluminum alloy reduces carbon footprint substantially. For eco-conscious architects and builders, choosing aluminum stair treads represents an investment in longevity and circular material economy.

Installation and Maintenance: Extending Safe Use

Installation: Lightweight aluminum treads (often under 3 kg per linear foot) reduce labor costs and wear-and-tear on stair framing.

Maintenance: Aluminum’s oxidative layer and anodized surfaces require minimal upkeep — periodic washing with non-abrasive detergents preserves slip characteristics without chemical degradation.

Lifespan: Properly installed, anti-slip aluminum stair treads last decades, making them a cost-effective safety solution.

Final Thoughts

Anti-slip aluminum stair treads aren’t simply about adding grip; they embody a synthesis of metallurgical science, engineering design, safety regulation adherence, and environmental forethought. By selecting the right alloy (commonly 6061-T6 or 3003-H14), proper tempering, and surface treatment, these stair treads perform reliably under diverse conditions while minimizing environmental impact.

In considering anti-slip options for staircases, thinking of aluminum stair treads beyond just their anti-slip characteristics — as a sustainable, efficient, and durable material solution — can unlock long-term value not only for individual users but also the planet.

Written by an environmental engineer specializing in sustainable material applications within industrial safety infrastructure.

https://www.al-alloy.com/a/anti-slip-aluminum-stair-tread.html