Mirrored Sublimation Aluminum Sheets Metal Signage Printing Blanks

Mirrored sublimation aluminum sheets metal signage printing blanks represent a cutting-edge solution in the realm of customized signage and decorative metal printing. Engineered to optimize the sublimation process, these sheets combine a flawless, highly reflective mirror finish on aluminum substrate with enhanced heat and ink adhesion properties. Offering remarkable clarity, vibrancy, and durability, they are ideal for businesses, designers, and fabricators seeking premium signage that stands out.

Material: Aluminum alloy (commonly 3003 or 5052 series)

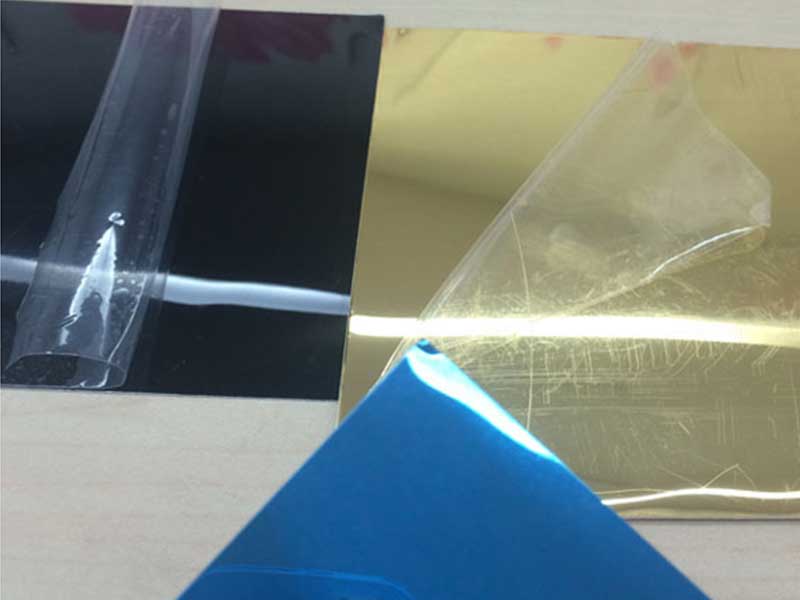

Finish: Mirror-polished reflective surface, specifically coated for sublimation printing

Thickness Options: Typically 0.5mm to 3.0mm, customizable depending on application

Standard Sheet Sizes: 24" x 48", 36" x 72" or customizable to customer requirements

Chemical Composition and Properties

The aluminum alloys used are carefully selected based on corrosion resistance, formability, and surface smoothness features vital for customization:

From a production standpoint, our mirrored sublimation aluminum sheets present a unique set of challenges compared to standard aluminum printing blanks. The mirrored finish, achieved through a meticulous polishing and coating process, requires incredibly precise handling throughout the manufacturing process. Even minor scratches or imperfections become highly visible, leading to a higher rejection rate than with matte finishes. This means we have to be extra vigilant about cleanliness, utilizing specialized machinery, and training our staff on delicate handling techniques. Furthermore, the sublimation process itself necessitates careful temperature and pressure control to avoid damaging the delicate reflective coating. Balancing the need for a vivid print with the integrity of the mirror finish is a constant balancing act.

Personally, I find the end product – a vibrant, eye-catching sign with a luxurious mirrored backdrop – incredibly satisfying. It’s a testament to the precision and skill involved in every stage of production, from the initial alloying to the final quality inspection. Seeing these blanks transformed into impactful signage in diverse applications, from elegant storefront displays to custom artwork, reinforces the value of our meticulous work. The combination of the striking visual appeal and the durability of aluminum makes this a truly exceptional product, and I'm proud to be a part of its creation.

| Element | Typical Composition (%) for 3003 Alloy | Typical Composition (%) for 5052 Alloy |

|---|---|---|

| Aluminum (Al) | 96.8 - 99.0 | 94.7 - 97.8 |

| Manganese (Mn) | 1.0 - 1.5 | 0.10 max |

| Magnesium (Mg) | 0.05 - 0.20 | 2.2 - 2.8 |

| Iron (Fe) | 0.7 max | 0.4 max |

| Silicon (Si) | 0.6 max | 0.4 max |

| Copper (Cu) | 0.1 max | 0.1 max |

| Zinc (Zn) | 0.1 max | 0.25 max |

Features

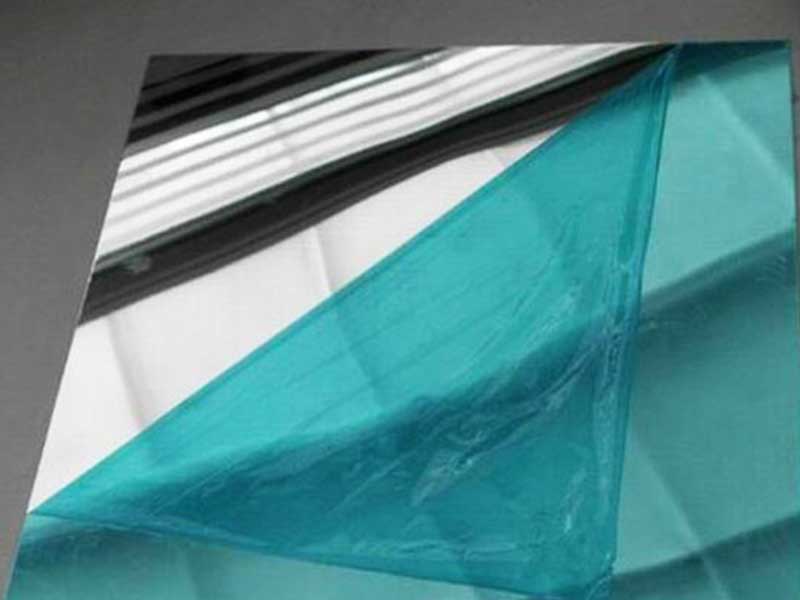

1. Superior Mirror Finish

- The sheets are precision-polished, resulting in an extremely smooth, sharp, and clear mirror reflection that boosts aesthetic appeal.

- The metallurgical polishing process ensures a uniform glossy surface ideal for high-definition printed graphics.

2. Sublimation-Optimized Coating

- Coated with a specialized polymer layer formulated for dye sublimation process, the surface enables superb ink absorption and color fastness.

- The coating not only enhances capturing detail but also provides excellent heat resistance for sublimation at typical temperatures (around 180°C to 210°C).

3. Excellent Durability

- Exhibits outstanding resistance to corrosion and tarnish due to the protective anodized layer beneath the sublimation coating.

- Offers sound resistance to UV exposure, allowing for outdoor signage usage without significant fading or degradation.

4. Lightweight and Rigid

- Aluminum’s natural properties make sheets both lightweight and durable, outperforming glass or acrylic mirror standings with much better impact resistance.

- Enables ease of transportation, installation, and handling.

5. Customizable Dimensions and Thickness

- Available in multiple thicknesses and sizes tailored for large-format signage, awards, nameplates, photo prints, and more.

- Sheet metal can also be laser cut or CNC routed for complex shapes.

Technical Specifications

| Parameter | Specification Range |

|---|---|

| Alloy Type | 3003 or 5052 Aluminum |

| Thickness | 0.5 mm to 3 mm |

| Reflectivity | ≥ 85% reflective mirror finish |

| Sublimation Coating Thickness | ~3 - 5 microns |

| Sheet Size | 24"x48", 36"x72" or customized |

| Operating Sublimation Temp | 180 °C - 210 °C (356 °F - 410 °F) |

| Weather Resistance | Excellent (UV resistant coating) |

| Bend Radius | ≥ Minimum bend radius for aluminum alloys (~3 x thickness) |

| Surface Hardness | Moderate (high for sublimation sheets; approx. 2H pencil hardness) |

Applications

1. Custom Metal Signage

Ideal for shops, offices, restaurants, and event branding requiring sleek mirrored names, logos, or directional signs with vibrant full-color prints.

2. Interior Decoration & Display Panels

Used for upscale decorative panels, feature walls, retail/custom retail display fronts, where attractive mirror shine combined with high-impact printed graphics add superior ambience.

3. Personal & Corporate Awards

Bespoke trophy plaques and awards with photographic-quality prints combined with the elegance of mirror-reflective surfaces.

4. Photography & Artwork Prints

Perfect for transferring high-resolution photographic images onto sturdy mirrored metal, delivering a unique presentation piece elevating art galleries and personal collections.

5. Promotional Items

Manufacture of unique giveaway products such as customized metal bookmarks, name badges, and business card holders.

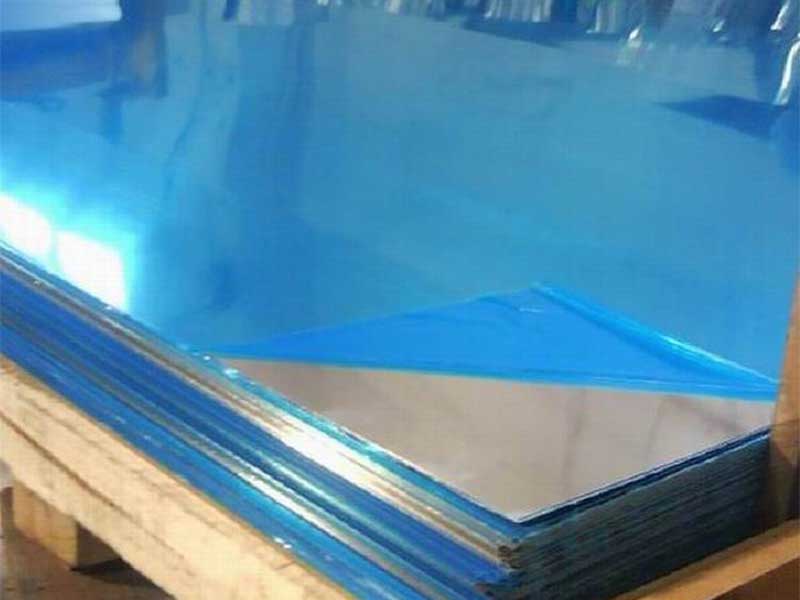

Handling and Usage Notes

- Store sheets in a clean environment to prevent abrasions or dust inclusion on sublimation coating.

- Surface delicate—avoid sharp abrasives during handling and cleaning.

- Recommended use a soft microfiber cloth and non-abrasive cleaning solutions.

- Follow sublimation temperature and pressure guidelines closely to prevent damage or defects.

- Test bend decreasing gauges on scrap to determine tension limits for shaping/curling after printing.

https://www.al-alloy.com/a/mirrored-sublimation-aluminum-sheets-metal-signage-printing-blanks.html