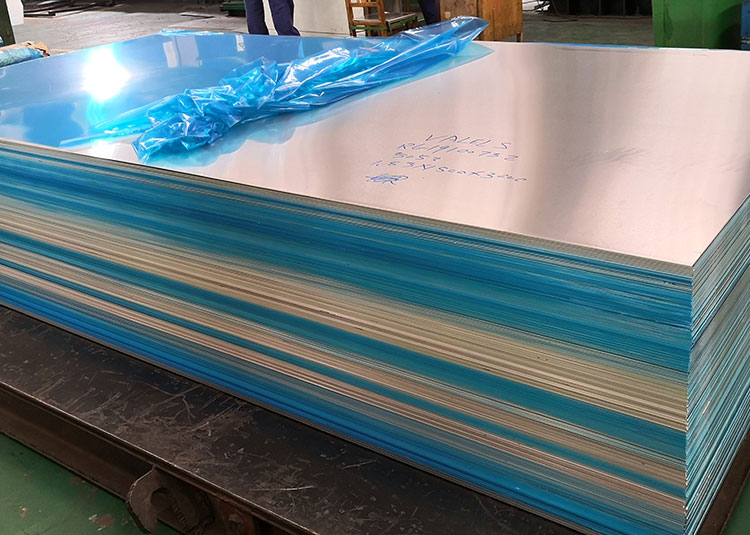

5059 h31 marine grade aluminum plate sheet

When it comes to marine environments, materials need to possess exceptional corrosion resistance, strength, and longevity. Among the prominent contenders, 5059 H31 marine grade aluminum plate sheet shines prominently.

What is 5059 H31 Marine Grade Aluminum?

5059 H31 aluminum belongs to the 5xxx series aluminum alloys, primarily alloyed with magnesium and traces of other elements like manganese and chromium to create a marine-grade product renowned for excellent corrosion resistance. The designation "H31" references its temper - meaning it is strain hardened and partially annealed, balancing strength and ductility ideal for harsh environments.

5059-H31 marine grade aluminum plate is a workhorse around here. We see a lot of it go out for boat hulls, deck plating, and even some specialized applications like components for desalination plants. What strikes me most isn't just its corrosion resistance – though that's obviously crucial in a saltwater environment – but its formability. We frequently get requests for custom bends and shapes, and the H31 temper provides a great balance between strength and ductility. It's not as easily worked as some softer alloys, but the resulting strength and longevity justify the extra effort. The consistent quality from our suppliers is key, as any variation in temper can significantly impact the final product's performance and lifespan, leading to rework or, worse, field failures.

Personally, I've seen firsthand how critical proper welding procedures are with 5059-H31. Improper techniques can lead to cracking and porosity, severely compromising the integrity of the finished product. We've invested heavily in training our welders on the specifics of this alloy, emphasizing pre-weld cleaning, the correct filler metal selection, and post-weld heat treatments. Seeing a flawlessly welded 5059-H31 component, especially a complex one, is incredibly satisfying. It's a testament to the skill of our team and the material's inherent quality – a silent promise of years of service in even the

This grade complies with several international maritime and shipbuilding standards such as ASTM B928 (for marine aluminum alloys) and often meets military specifications for vessel construction.

Chemical Composition of 5059 Alloy

The chemical makeup of the 5059 aluminum impacted the alloy's corrosion resistance and mechanical performance significantly. Below is a typical composition range (in % weight):

| Element | Percentage (%) |

|---|---|

| Magnesium (Mg) | 5.0 - 6.0 |

| Aluminum (Al) | Balance |

| Manganese (Mn) | 0.5 - 1.0 |

| Chromium (Cr) | 0.15 - 0.35 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.25 |

| Copper (Cu) | ≤ 0.3 |

| Zinc (Zn) | ≤ 0.3 |

| Others | ≤ 0.05 (each); ≤ 0.15 (total) |

The relatively high magnesium content enhances strength and corrosion resistance, particularly in saltwater conditions compared to other aluminum alloys.

Temper and Mechanical Properties: H31

Tempering H31 means the alloy was strain hardened and stabilized after forming or processing. This temper provides:

- Higher tensile strength than full anneal but retains enough formability needed during shipbuilding.

- Good fatigue resistance - critical for vessels exposed to constant wave and operational stresses.

Typical Mechanical Properties for 5059 H31

| Property | Value |

|---|---|

| Ultimate Tensile Strength | 350 - 400 MPa |

| Yield Strength (0.2% offset) | 290 - 340 MPa |

| Elongation at Break | 10 - 15% |

| Hardness (HB) | Around 75 - 85 |

| Density | ~ 2.66 g/cm³ |

Functional Advantages for Marine Applications

1. Outstanding Corrosion Resistance

Compared to older Corten steel plates or other aluminum grades (5005, 5083), 5059 alloy forms a stable oxide film resisting pitting and crevice corrosion even in saltwater environments. The presence of chromium and manganese alongside magnesium adds wholistic corrosion defenses.

2. Superior Strength-to-Weight Ratio

The alloy delivers outstanding strength maintaining relatively low weight: critical in speeding up yacht vessels or military ships reduction of fuel consumption and start-up time.

3. Good Weldability

Many marine grades fall short due to weld cracking risks. The 5059 H31 allows arc and TIG welding with minor distortion risk after careful control of heat inputs and post weld treatments.

Common Applications of 5059 H31 Marine Aluminum Plate Sheet

Naval Vessels and High-Speed Boats: Known for excellent ballistic properties and lightweight, it’s routinely selected for patrol boats, rigid-hull inflatable ships, and amphibious vehicles.

Yacht & Luxury Boats: Its polished metallurgical properties provide handsome finishing allowing the sleek wear on pristine yachts and leisure craft subject to splashing seawater.

Structural Marine Components: Decks, hull plating, superextensions, and bulkheads employ this alloy thanks to its long service life fí bite from harsh sea salt air.

Offshore Platforms & Mining Industry: Maritime platforms for drilling routinely rely on this grade due to equipment exposure requiring marine-grade resiliency amongst other stresses.

Standards and Compliance

- ASTM B928/B928M: Synthetic marine aluminum alloy sheets.

- ISO 6361: Wrought aluminum and aluminum alloy sheets for marine use.

- MIL-HDBK-5 and NAVSEA Specification considerations if used directly in intl naval applications.

Care and Processing Tips for End-Use Shipping Clients

From an end-user perspective:

- Handling: Avoid pre-exposure to environments causing accelerated fatigue.

- Welding: Preheat or controlled post-weld heat treatments ensure the strengthening from strain-hardening remains effective.

- Finishing: The aluminum’s anodizing capacities ensure further corrosion improvements available to builders.

https://www.al-alloy.com/a/5059-h31-marine-grade-aluminum-plate-sheet.html