2a12 5052 5083 6061 Aluminum Sheet

Aluminum has undeniably transformed the industrial landscape, serving as a lightweight yet sturdy material capable of adapting to a multitude of applications. In our exploration of four distinct aluminum alloys—2A12, 5052, 5083, and 6061—we aim to dissect their unique properties and optimally reflect their versatility in everyday applications. these alloys from a nuanced perspective can greatly impact decision-making mechanics in various fields, from aerospace to marine applications, and beyond.

A Dive Into Alloy Composition

Alloy 2A12: The Aerospace Superstar

2A12 is recognized for its high strength and excellent fatigue resistance, which makes it a darling in the aerospace sector. Composed mainly of aluminum, copper, and other elements like manganese and silicon, 2A12 provides outstanding weight-to-strength advantages. The heat treatment process elevates its mechanical properties, allowing it to endure hostile environments typical of aviation.

Properties:

- Tensile Strength: Approximately 570 MPa

- Yield Strength: About 420 MPa

- Corrosion Resistance: Moderate; suitable for coated applications

Alloy 5052: The Workhorse of Marine Applications

5052 aluminum alloy comes with magnesium as its primary alloying element which grants it splendid corrosion resistance—ideal for marine conditions. It possesses forgiven weldability, high workability, and moderate temperature strength. This alloy is often employed for fabricating fuel tanks, boat hulls, and marine structures, mirroring both adaptability and durability.

Properties:

- Tensile Strength: Approximately 290 MPa

- Yield Strength: About 230 MPa

- Corrosion Resistance: Very good; often utilized in coastal areas

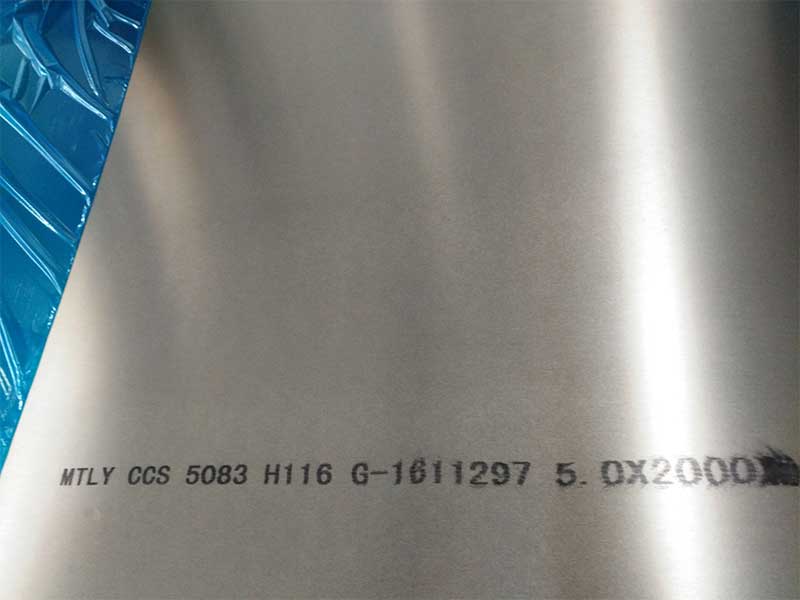

Alloy 5083: The Heavyweight Champion

5083 serves as an ideal choice for environments exposed to seawater or harsh weather conditions due to its exceptional corrosion resistance. Often utilized in shipbuilding, offshore oil rigs, and pressure vessels, this alloy balances strength and lightweight characteristics seamlessly. Additionally, it maintains exceptional resistance to marine environments and azimuthal processes.

Properties:

- Tensile Strength: Approx. 315 MPa

- Yield Strength: About 260 MPa

- Corrosion Resistance: Outstanding; among the highest in aluminum alloys

Alloy 6061: The Jack of All Trades

6061 is undoubtedly one of the most versatile aluminum alloys with widespread use in construction, automotive, aerospace, and even consumer goods. Lightweight and weldable, it offers moderate to high strength with reasonable machinability. 6061 finds itself in everything from structural components to automotive parts, showcasing its multifaceted usability.

Properties:

- Tensile Strength: Approx. 310 MPa

- Yield Strength: About 275 MPa

- Corrosion Resistance: Good; works well in many environments

Comparison of Tempering Conditions

Aluminum alloys can be modified through heat-treating and/or cold-working processes, referred to as tempering. Each alloy mentioned above has specific tempering processes that enhance its characteristics:

| Alloy | Common Tempering Processes | Characteristics |

|---|---|---|

| 2A12 | T3, T4, T6 | High strength and weldability post-heat treatment |

| 5052 | H32, H34 | Excellent workability and corrosion resistance |

| 5083 | H111, H116 | Strong resistance to seawater and wind |

| 6061 | T6, T651 | Versatile, excellent mechanical properties |

Implementation Standards

When discussing standards, it's essential to consider implications—certifications or grade specifications beneficial for quality assessments within specific industries. Here's what values to look for when concerning these aluminum sheets:

- ASTM B221: Covers aluminum and aluminum-alloy extruded bars, rods, shapes, wire, and tubing, giving a general guideline for their acceptance criteria.

- ISO 9001: A standard on quality requirements ensuring that manufacturing processes remain consistent.

- NADCAP (National Aerospace and Defense Contractors Accreditation Program): This may apply specifically for aerospace alloys, bolstering material credibility in sourcing.

https://www.al-alloy.com/a/2a12-5052-5083-6061-aluminum-sheet.html