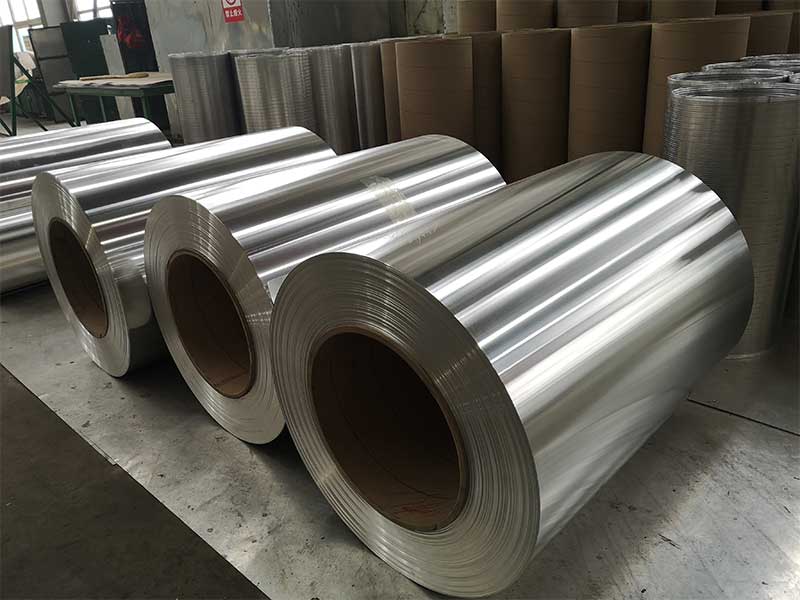

20 gauge aluminum coil

The 20 gauge aluminum coil is a versatile, cost-effective, and widely used aluminum product in multiple industries. Offered in continuous coil form and typically produced from commercial-grade aluminum alloys, 20 gauge coils provide a balance of strength, formability, corrosion resistance, and aesthetic finish — making them ideal for roofing, cladding, HVAC, fabrication, and signage applications.

- Thickness: 20 gauge (U.S. standard) = 0.036 inches (0.914 mm) nominal

- Form: Coil (wide stock rolled and wound)

- Typical alloys: 3003, 3105, 5052, 6061 (selection based on required performance)

- Temper: H14/H24/H32 (work-hardened) or O (annealed) depending on application

- Widths: Customizable; common widths 24", 36", 48", and wider

- Coil weight: Depends on width and coil length; commonly 1–10 metric tons per coil

Features and Benefits

- Lightweight: High strength-to-weight ratio reduces structural load and shipping costs.

- Corrosion Resistance: Excellent natural resistance due to aluminum oxide film; improved with alloys like 3003 and 5052.

- Formability: Good drawability and bendability for roofing panels, gutters, and architectural trim.

- Weldability: Many alloys are readily weldable (e.g., 5052, 3003). Some alloys (like 6061) require proper procedures.

- Thermal and Electrical Conductivity: Useful where heat dissipation or electrical conductivity is required.

- Recyclability: Aluminum is highly recyclable without loss of properties, lowering lifecycle environmental impact.

- Aesthetic Finishes: Available in mill, pre-painted (PVDF, polyester), anodized, or coated options for design flexibility.

Technical Specifications

| Parameter | Typical Value |

|---|---|

| Gauge | 20 (U.S. Standard) |

| Thickness (nominal) | 0.036 in (0.914 mm) |

| Tolerance | ±0.001–0.004 in (varies by standard and mill spec) |

| Density | 2.70 g/cm³ |

| Coil ID (inner diameter) | 508 mm (20") or 610 mm (24") typical — customizable |

| Coil OD (outer diameter) | Depends on coil weight and length |

| Surface finish | Mill, polished, brushed, anodized, painted (PVDF or polyester) |

| Typical alloys | 3003, 3105, 5052, 6061 |

| Tempers | O, H14, H18, H24, H32 (varies by alloy) |

| Max width | Up to 1500 mm+ (mill-dependent) |

Chemical Composition (Typical Alloys)

Note: Composition ranges vary by standard (ASTM, EN, JIS). Below are representative compositions.

Alloy 3003 (Mn alloy)

Al: base

Mn: 1.0–1.5%

Fe: ≤0.7%

Si: ≤0.6%

Cu: ≤0.05%

Others: trace

Alloy 3105 (Al-Mn, low Cu)

Al: base

Mn: 0.2–1.0%

Fe: ≤0.7%

Si: ≤0.6%

Cu: ≤0.1%

Alloy 5052 (Al-Mg, higher strength & corrosion resistance)

Al: base

Mg: 2.2–2.8%

Cr: 0.15–0.35%

Fe: ≤0.4%

Si: ≤0.25%

Cu: ≤0.1%

Alloy 6061 (Al-Mg-Si, heat-treatable)

Al: base

Mg: 0.8–1.2%

Si: 0.4–0.8%

Cu: 0.15–0.4%

Cr: 0.04–0.35%

Fe: ≤0.7%

Mechanical Properties (Representative Values)

Values depend on alloy and temper. Below are typical ranges for 20 gauge material.

| Alloy/Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 3003 - H14 | 110–140 MPa | 65–95 MPa | 6–12% |

| 3105 - H14 | 120–150 MPa | 70–100 MPa | 6–12% |

| 5052 - H32 | 200–260 MPa | 120–170 MPa | 8–12% |

| 6061 - T6 (if used) | 270–310 MPa | 240–280 MPa | 8–12% |

Performance Characteristics

- Corrosion resistance: Excellent in atmospheric conditions; 5052 offers superior resistance in marine or high-moisture environments.

- Fatigue performance: Good for cyclic loading when properly designed; avoid sharp notches.

- Thermal performance: Low coefficient of thermal expansion vs steels; high thermal conductivity aids heat transfer applications.

- Anodizing and painting: 20 gauge coils accept anodizing and high-quality PVDF coatings for long-term color retention and weathering performance.

Common Applications and Use Cases

- Construction and roofing: Standing seam roofs, soffits, gutters, flashings, and cladding panels.

- Architectural facades: Pre-painted or anodized coil for rainscreens and exterior panels.

- HVAC: Ductwork, plenums, and coils where corrosion resistance and lightweight are valuable.

- Transportation: Body panels, trim, and interior components in automotive and rail (depending on alloy).

- Signage and graphics: Substrate for signs, panels, and industrial labels.

- Fabrication and OEM parts: Enclosures, housings, brackets, and formed components.

- Marine hardware and components: Using 5052 alloy for enhanced corrosion resistance.

Finishing and Processing Options

- Cutting: Slitting, shearing, laser cutting (depending on coil processing).

- Forming: Bending, roll-forming, stamping; temper selection influences springback.

- Coating: PVDF (Kynar) for high-end architectural finishes; polyester for economy options.

- Anodizing: Provides durable oxide finish with varying thickness classes.

- Protective film: Temporary films for painted or delicate finishes during handling.

- Edge treatments: Deburring and protective edge seals for safety and corrosion prevention.

Handling, Storage, and Installation Guidelines

- Store coils in dry, covered areas to prevent moisture accumulation and staining.

- Use appropriate lifting equipment (C-hooks, spreader bars) to avoid coil damage.

- Avoid cross-contamination with dissimilar metals and corrosive substances.

- During forming, take into account springback and use appropriate tooling for 0.914 mm thickness.

- For exterior installations, allow for thermal expansion and provide appropriate fastener fixation compatible with aluminum.

Quality Standards and Testing

- Manufactured to meet standards such as ASTM B209 (sheet and plate), ASTM B209/B209M, EN 485 for aluminum sheet and strip, and specific coil mill certificates.

- Typical tests: thickness/tolerance inspection, mechanical property testing (tensile/yield), chemical analysis, surface quality inspection, coating adhesion and thickness tests for painted coils.

Why Choose 20 Gauge Aluminum Coil?

- Balanced thickness: 20 gauge (0.036") hits a sweet spot — thick enough for structural and exterior use, yet thin enough to be easily formed and economical.

- Versatility: Suitable for a wide range of construction, industrial and consumer applications.

- Long-term performance: Corrosion resistance and finish options provide durable, low-maintenance solutions.

- Cost-effective: Lower weight compared to steel reduces material handling and transportation costs; recyclability improves lifecycle sustainability.

- Customizable: Available in several alloys, tempers, finishes, and widths to meet project-specific needs.

Ordering Considerations

When specifying 20 gauge aluminum coil, provide the following details for an accurate quote and delivery:

- Alloy and temper (e.g., 3003-H14 or 5052-H32)

- Width and coil inner/outer diameters

- Length or coil weight

- Surface finish (mill, anodized, PVDF paint)

- Edge condition and slitting requirements

- Standard/certification requirements (e.g., ASTM, EN)

- Packing and protective film requirements

| Item | Typical Value |

|---|---|

| Product | 20 gauge aluminum coil |

| Thickness | 0.036 in (0.914 mm) |

| Common Alloys | 3003, 3105, 5052, 6061 |

| Tempers | O, H14, H24, H32 |

| Finish Options | Mill, anodized, PVDF, polyester |

| Applications | Roofing, cladding, HVAC, signage, fabrication |

| Advantages | Lightweight, corrosion-resistant, formable, recyclable |