7mic Aluminium foil jumbo roll for lamination packaging

7mic aluminium foil jumbo roll is a high-performance, ultra-thin aluminium foil designed for lamination packaging applications. At 7 micrometers thickness, it balances excellent barrier properties (moisture, oxygen, light), malleability, and strength, making it ideal for flexible packaging, pouches, lidding, and multi-layer laminated structures. This product is optimized for high-speed converting, heat sealing compatibility and consistent winding for jumbo-roll processing.

Features

- Ultra-thin and uniform: Nominal thickness 7 µm with tight thickness tolerance for consistent lamination performance.

- Superior barrier properties: Excellent resistance to oxygen, moisture vapor, light and aromas when used in laminated structures.

- Good formability and fold endurance: Easy to crease and fold without brittle cracking.

- High tensile strength and elongation: Robust for high-speed converting and handling.

- Smooth surface finish: Clean, defect-minimized surface for adhesion in solventless and solvent-based laminations.

- Excellent roll geometry: Accurate OD/ID and edge trim to support continuous unwinding and printing/lamination lines.

- Good heat reflectivity: Adds thermal / radiant protection in barrier laminates.

- Recyclable and non-toxic: Aluminium is infinitely recyclable and inert for food contact applications when processed to regulatory standards.

- Customizable widths and lengths: Produced to customer specifications for jumbo roll diameters and core sizes.

- Compatible with adhesives & adhesives systems: Works with common solvent-based, solventless (e.g., polyurethane), and water-based adhesives suited for lamination.

Typical Applications

- Flexible food packaging (snack foods, coffee, confectionery)

- Pouches and sachets (vacuum, retort or standard)

- Lidding foils for trays and cups (when laminated with heat-seal layers)

- Medical packaging (sachets for sterile components, barrier pouches)

- Barrier layers in multi-web structures for pharmaceuticals and nutraceuticals

- Personal care and cosmetic sachets

- Industrial packaging where barrier against moisture, oxygen or light is required

- Laminated roll stock for printing and converting

Technical Specifications

| Property | Typical Value | Tolerance / Notes |

|---|---|---|

| Nominal thickness | 7 µm (micrometers) | ± 0.5 µm typical (confirm with supplier) |

| Alloy | 8006 / 8011 / 1235 (common) | Exact alloy depends on supplier and required mechanical / surface properties |

| Temper | O (annealed) / H14 - H18 (lightly work-hardened) | O temper most common for high formability; specific temper supplied on request |

| Density | 2.70 g/cm³ | Physical property of aluminium |

| Tensile strength (YS) | 100–200 MPa (varies with alloy/temper) | Typical range for thin foil alloys and tempers |

| Elongation (%) | 10–35% | Dependent on alloy and temper |

| Surface finish | Bright / Dull available | Bright for better reflectivity; dull for improved adhesion surface |

| Surface roughness (Ra) | 0.2–0.8 µm typical | Depends on rolling and finishing process |

| Core ID | 76 mm (3") or 152 mm (6") typical | Other core sizes available on request |

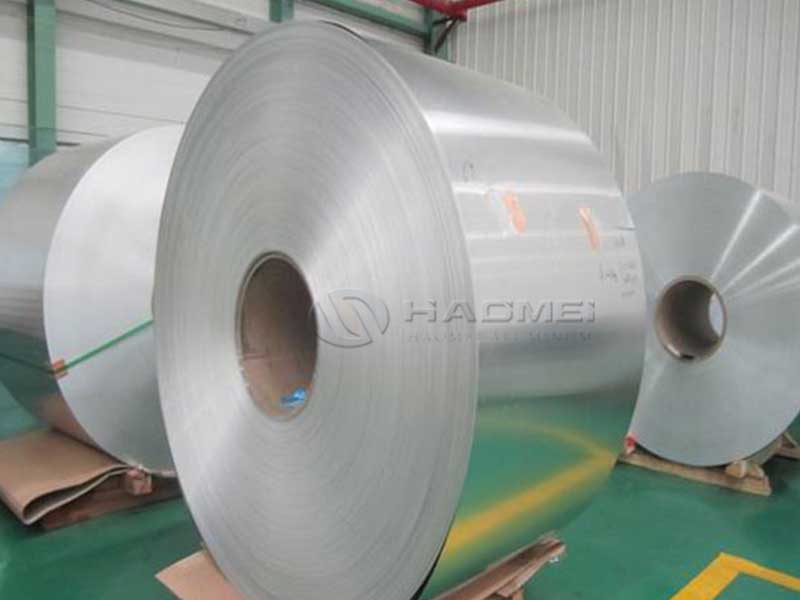

| Roll OD | Up to 1000 mm+ depending on length and core | Customizable; jumbo roll dimensions quoted per order |

| Width | Up to 1650 mm typical | Custom widths available; slit to customer spec |

| Maximum roll weight | Per mill capacity; commonly up to 2,000 kg | Supplier-dependent—confirm handling limits |

| Oxide layer | Naturally formed Al2O3 | Provides corrosion resistance |

| Barrier performance (O2) | Very low oxygen transmission when laminated | Aluminium foil is essentially impermeable to gases |

| Moisture Vapor Transmission Rate (MVTR) | Near zero for continuous foil layer | Depends on laminate structure & seals |

| Food contact compliance | Compliant when processed per regulations | e.g., EU, FDA—certificate of compliance issued per batch on request |

| RoHS / REACH | Typically compliant | Certificates available upon request |

| Recyclability | 100% recyclable | Aluminium infinitely recyclable without loss of properties |

Alloy & Temper — Typical Guidance

| Alloy | Characteristics | Recommended Temper |

|---|---|---|

| 1235 (Commercially pure) | High formability, excellent corrosion resistance, good barrier properties | O (annealed) |

| 8006 / 8111 / 8011 | Designed for foil and packaging uses, improved strength and mechanical stability | O to H16 depending on processing |

| 8011A | Common for household and packaging foils with good drawability | O temper |

Note: Specific alloy selection should be based on required mechanical properties, surface finish, and converting needs. Consult supplier for detailed metallurgical data.

Lamination & Converting Considerations

- Adhesion: Surface cleanliness and surface roughness affect bond strength. Use primers or corona treatment where needed.

- Heat/Temperature: Consider temperature stability of adhesive and heat-seal layers. Aluminium itself has high thermal conductivity—manage heating profiles to avoid overheating sealing layers.

- Wrinkle control: Proper tension control and edge trim reduce wrinkling during laminating and rewinding.

- Slitting: Sharp, well-maintained slitting tools are required to ensure clean edges and consistent width.

- Handling: Use adequate storage (dry, clean) and handling equipment to avoid contamination and mechanical damage.

- Compatibility: Check chemical compatibility of adhesives and inks. Some adhesives require surface treatment for optimal bonding.

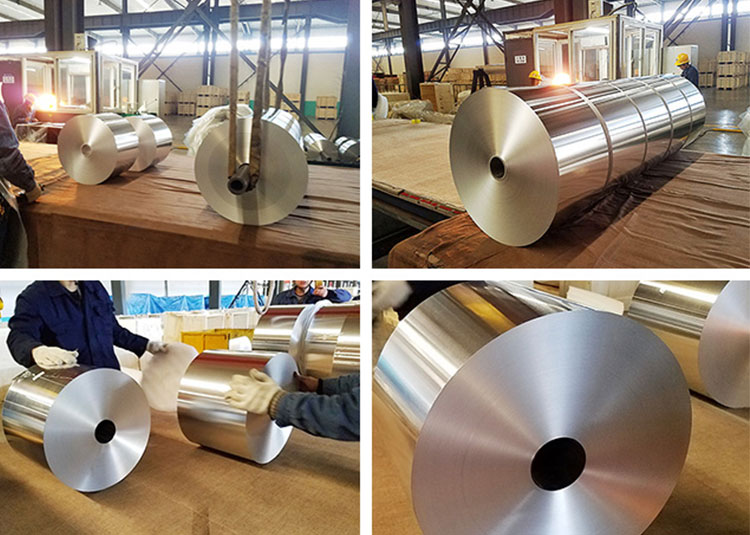

Packaging, Storage & Handling

- Pack rolls in protective paper or film and on wooden or steel pallets.

- Store in a clean, dry indoor location at stable temperatures to prevent moisture or contamination accumulation.

- Avoid contact with aggressive chemicals and rough surfaces to prevent surface defects.

- Use appropriate forklifts/cranes for heavy jumbo rolls; observe core load limits.

Quality & Certification

- Batch testing for thickness, tensile, elongation, and composition available.

- Certificates of Analysis (CoA) and Compliance (food contact, REACH, RoHS) provided upon request.

- Inline inspection and surface defect control to minimize pinholes and inclusions that can affect barrier performance.

Ordering Information & Customization

- Typical order options: thickness (7 µm standard), width, roll OD, core ID, alloy, temper, finish (bright/dull), slitting and packaging.

- MOQ (minimum order quantity) and lead times depend on mill capacity and custom specifications.

- Samples and technical datasheets available for qualification trials.

Advantages Over Thicker Foils in Lamination

- Material savings and lower weight in the packaging structure.

- Better flexibility and foldability for pouches and sachets.

- Easier conformability to product shapes in lidding and flexible packaging.

- Maintains high barrier performance when properly laminated and sealed.

Limitations & Mitigation

- Handling sensitivity: Very thin foils are more prone to mechanical damage—use controlled tension and protective interleaves.

- Pinholes: Manufacturing quality must be high to reduce pinholes—specify pinhole testing and inspection.

- Mechanical strength: Lower absolute puncture resistance vs thicker foils—can be mitigated by laminate design (e.g., adding protective outer layers).

Typical Technical Data Sheet (Example)

| Parameter | Value |

|---|---|

| Thickness | 7 µm |

| Alloy | 8011 (example) |

| Temper | O |

| Width | 1250 mm (custom) |

| ID | 76 mm |

| OD (max) | 900 mm |

| Roll weight | 750–1200 kg (depending on OD) |

| Surface finish | Bright |

| Tensile strength | 130 MPa (example) |

| Elongation | 20% (example) |

| Regulatory | Food-grade compliant (per request) |

(Actual values to be confirmed on order-specific CoA.)

https://www.al-alloy.com/a/7mic-aluminium-foil-jumbo-roll-for-lamination-packaging.html