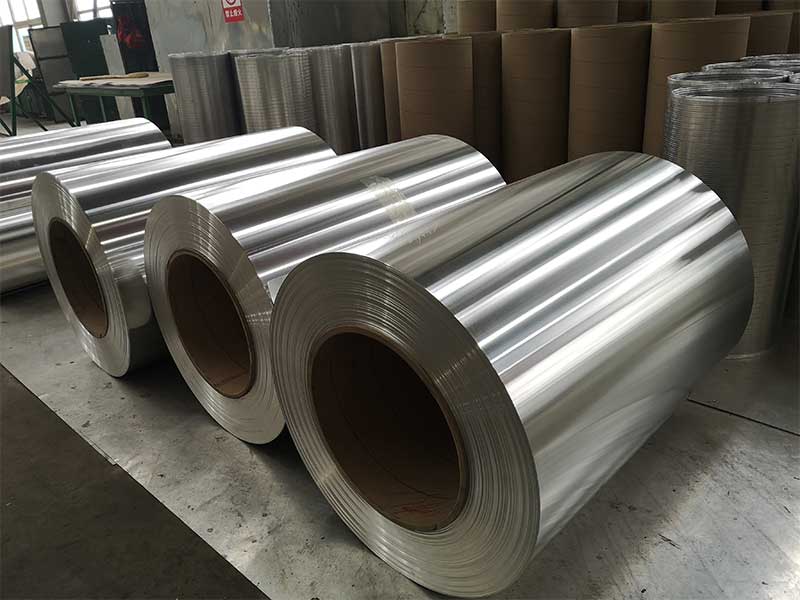

6061 6063 5005 5052 Jumbo Coil Aluminum Roll Coil

When considering aluminum alloys for projects that range across industries from construction to automotive and beyond, the Jumbo Coil is a remarkable option. Specifically, the 6061, 6063, 5005, and 5052 alloys each have distinctive characteristics that cater to varied needs.

Aluminum Alloys: The Basic Structure

Aluminum alloys are classified into two primary categories: wrought and cast. The alloys in question – 6061, 6063, 5005, and 5052 – all belong to the wrought category, where metal is shaped by mechanical processes such as extrusion and rolling. Each alloy is another example of nature's adaptability, offering various compositional benefits, ultimately leading to incredible diversity in applications.

parameters governing the performance of these alloys include:

| Alloy | Primary Alloying Elements | Characteristics | Common Applications |

|---|---|---|---|

| 6061 | Magnesium, Silicon | Good machinability, corrosion resistance, welding potential | Structural applications, automotive parts |

| 6063 | Magnesium, Silicon | Excellent extrusion characteristics, medium strength | Architectural applications, window frames, tubing |

| 5005 | Magnesium | Anodizing capabilities, good workability | Decorative structures, signage, electrical parts |

| 5052 | Magnesium, Chromium | High fatigue strength, excellent corrosion resistance | Marine and automotive components, pressure vessels |

The Alloys in Detail

6061: The All-Rounder

Whenever a universal solution is needed, 6061 aluminum alloy steps in. Known affectionately as the "workhorse" of aluminum, it demonstrates high strength-to-weight ratios and excellent corrosion resistance. Its extraordinary versatility, combined with attributes that support anodizing, makes this alloy ideal for structural components, automotive parts, and heavy-duty machinery.

One can find 6061 Jumbo coils expertly used in regions prone to adverse weather, gaining wide acceptance in marine industries due to its resilient nature.

6063: Architectural Beauty

Complex shapes have their perfect ally in the 6063 alloy. Often seen in the construction realm, its medium strength and great surface finish make it an architect's ally for intricately designed windows and facades. The responsive extrusion requirements work in tandem with the environment—think sustainable buildings, greenhouses, and so forth!

Utilizing 6063 jumbo coils opens pathways to not just functionality but also aesthetic beauty. With anodized finishes, these coils delineate a canvas where creativity meets durability.

5005: The Aesthetic Choice

For those who value both design and utility, the 5005 alphanumeric series delivers spectacular anodizing capabilities. When structure sometimes takes a backseat to appearance, 5005 proves its worth with rich coloring options suitable for striking signage or architectural showcases. An essential feature is the effective compatibility with dyes used in finishing, helping designers achieve aesthetics that capture attention in multiple settings.

Commonly used in interior design and signage, 5005 LNG coil options can transform interfaces into mood-enhancing art with hardiness to match.

5052: Reliability Under Stress

For instances demanding unparalleled strength, especially against corrosion, the 5052 aluminum alloy embodies all that one seeks. Extensive fatigue resistance makes it a go-to candidate for marine applications, pressure vessels, and transportation sectors. Often meet demanding performance requirements without wavering in structural integrity, 5052's combination of elongation capacity and corrosion resistance generates reliability, ensuring components withstand the test of challenging environments.

Implementation Standards & Tempering

In working with these coils, implementation standards and proper tempering play an essential role. Common standards governing quality include:

ASTM Standards (American Society for Testing and Materials)

- ASTM B221 for structural aluminum extrusions

- ASTM B209 for flat-rolled aluminum products

Temper Definitions

- T5: Cooled from an elevated temperature shaping process and artificially aged.

- T6: Solution heat-treated and artificially aged.

- H: Strain-hardened (e.g. H32, H34 for work-hardened properties).

the temper is crucial, as it aligns with the anticipated service conditions of specific applications.

Strength & Chemical Properties

These selected aluminum alloys showcase unique qualities substantial to their performance:

| Alloy | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Corrosion Resistance | Anodizing Capability |

|---|---|---|---|---|

| 6061 | 275 | 310 | Excellent | Great |

| 6063 | 240 | 260 | Good | Excellent |

| 5005 | 210 | 220 | Good | Excellent |

| 5052 | 210 | 270 | Excellent | Good |

https://www.al-alloy.com/a/6061-6063-5005-5052-jumbo-coil-aluminum-roll-coil.html