Mirror Finish Aluminum Coil Aluminum Alloy

A mirror finish is often treated like a purely visual achievement: the coil looks glossy, reflections are sharp, and the surface "sells itself." But from the perspective of an aluminum alloy specialist, mirror finish is less like makeup and more like a contract. It is a promise that the alloy chemistry, temper, rolling schedule, surface cleanliness, and protection system have all cooperated-because mirror surfaces are honest. They do not hide pits, chatter marks, inclusions, or lubrication residue. They amplify them.

When customers ask for "mirror finish aluminum coil," they are usually buying more than beauty. They are buying controllable reflectivity, consistent anodizing behavior, stable formability, and a surface that can survive handling and fabrication without turning into a map of fingerprints and scratches. That combination is not accidental; it is engineered.

What "mirror finish" really means on coil

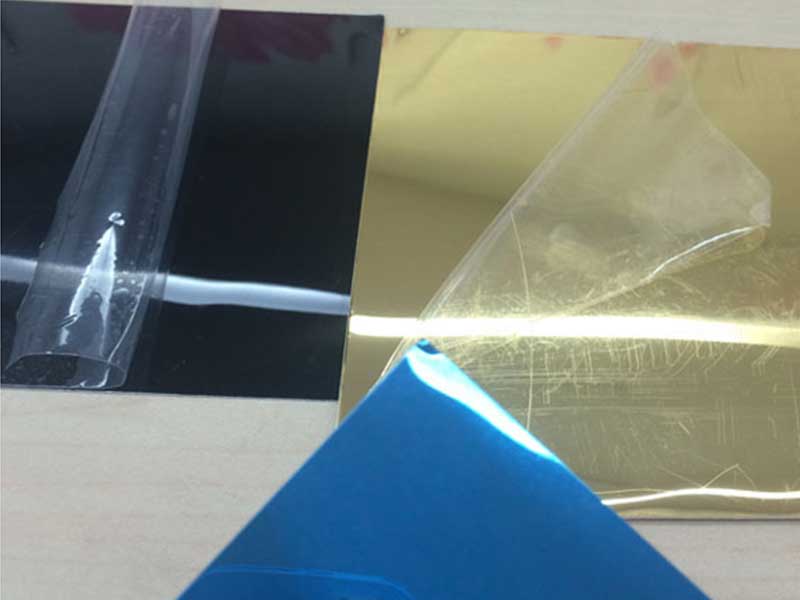

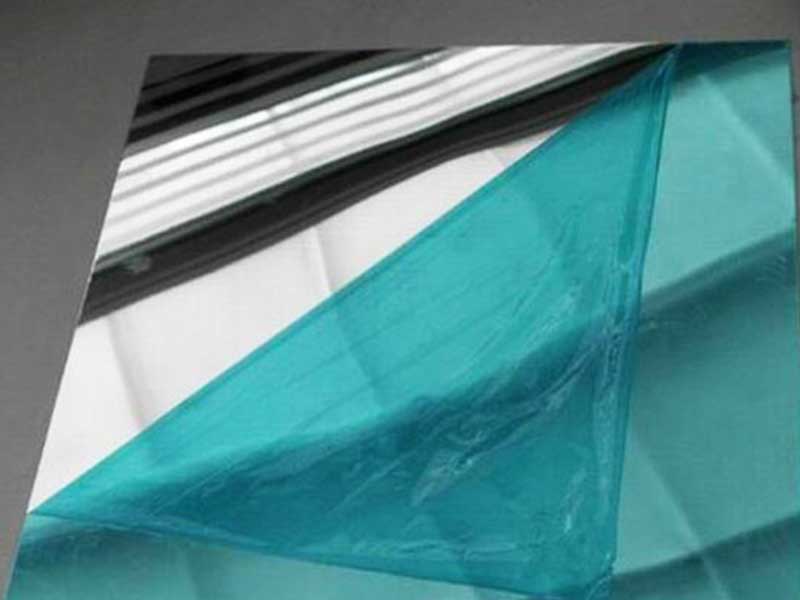

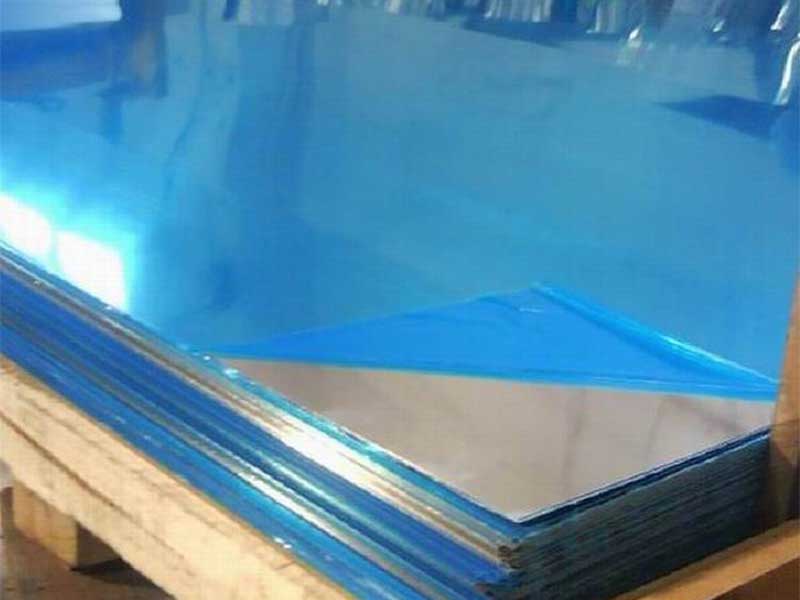

In practical terms, mirror finish aluminum coil is a bright-rolled or mechanically/chemically polished surface supplied in coil form, typically with a protective film. The performance indicator is not only gloss, but uniformity across coil length and width, and reproducibility lot to lot.

Common ways mirror finishes are produced include bright rolling (using highly polished work rolls and controlled lubrication), followed by optional processes such as tension leveling, degreasing, and sometimes chemical brightening or electropolishing if a higher optical clarity is required. For applications like lighting reflectors, interior trim, signage, appliance panels, or decorative architectural parts, mirror behavior must remain stable after forming, cutting, and surface treatments.

Mirror finish is also unforgiving to downstream processing. A fabricator who can tolerate minor rolling marks on a matte sheet will struggle with mirror coil if the slitter has burr issues or if the press tool has micro-galling. In that sense, mirror aluminum coil acts like a "process audit" for the whole supply chain.

Alloy selection: brightness is a metallurgical decision

Not every aluminum alloy wants to be a mirror. High-magnesium alloys can be strong, but they tend to oxidize and show surface "grain" more readily. Alloys in the 1xxx and 3xxx families generally provide the best balance of brightness, anodizing uniformity, and formability for mirror coil.

Typical alloy choices for mirror finish coil include:

- 1050, 1060, 1070, 1100: excellent brightness potential, high reflectivity, very good anodizing response, best for reflectors and decorative surfaces where maximum optical clarity matters.

- 3003, 3004: good formability and strength, widely used for appliance panels and trim; brightness can be very good with bright rolling, though ultimate reflectivity can be slightly below high-purity 1xxx alloys.

When your end use includes deep drawing or aggressive forming, 3xxx alloys can provide a safer forming window. When the end use is optical-lamp reflectors, solar reflectors, high-end decorative panels-higher purity 1xxx alloys usually win.

Temper and thickness: the quiet drivers of surface reality

Mirror finish coil is commonly supplied in O (annealed), H14, H16, H18, and sometimes H22/H24 tempers, depending on the forming needs and the required stiffness.

- O temper: best for deep drawing and complex shapes, but surface can be more susceptible to handling marks.

- H14/H24: a frequent "sweet spot" for trim and panels, offering moderate strength with workable formability.

- H18: higher hardness for stiffness and flatness-critical parts, but less forgiving in forming.

Typical thickness ranges are about 0.2–3.0 mm for most decorative and reflector coil applications, with narrower specialty ranges depending on the industry. Coil width is often application-specific, with tighter width tolerances required for automated lines.

In real production, mirror quality is strongly linked to tension leveling, residual stress, and coil set control. A mirror surface that waves under light is not perceived as mirror, even if its roughness is low. Flatness, therefore, is part of the "optics."

Implementation standards and practical acceptance points

Mirror finish aluminum coil is often supplied to general aluminum sheet and coil standards such as ASTM B209 or EN 485 for dimensional and mechanical properties. Surface quality, reflectivity, and protective film requirements are usually controlled by purchase specification because mirror appearance is highly application-sensitive.

In commercial practice, customers typically define acceptance by a combination of:

- Visual inspection under defined lighting and distance

- Surface roughness targets (Ra), when measurable requirements are needed

- Gloss or reflectance targets for reflector applications

- Limits on roll marks, pits, scratches, edge damage, and oil stains

- Film type, thickness, adhesion, and removability requirements

A useful viewpoint is to treat mirror coil like a semi-finished optical component. You do not only buy metal; you buy a surface state with a controlled "history." That is why suppliers emphasize clean rolling, controlled annealing atmospheres, and packaging discipline.

Surface protection: the invisible part of mirror value

Mirror coil almost always needs surface protection, because any micro-scratch becomes a macro-defect after installation under directional lighting. Common protections include PE films (clear or blue), paper interleaving, and sometimes coated systems.

If the coil will be laser cut, bent, or lightly stamped, the film must balance adhesion and clean removal. Excessive adhesion can leave glue residue; too little adhesion invites scuffing. For anodizing, film and adhesive selection matters because residue can cause streaking or color non-uniformity.

Tempering and heat treatment considerations

Most mirror coil alloys in 1xxx and 3xxx series are non-heat-treatable in the precipitation-hardening sense. Their "tempering" is primarily work hardening and annealing control.

process notes that influence mirror outcome:

- Annealing must be controlled to avoid oxidation and surface discoloration; furnace cleanliness and atmosphere control affect final brightness.

- Work roll condition is critical; roll micro-defects print through to the surface.

- Tension leveling must be tuned; excessive tension can create stretcher strains or localized yield patterns that show under reflection.

Chemical properties: representative composition table

Below is a practical reference table for common mirror-finish coil alloys. Actual limits depend on the exact standard version and supplier practice; always confirm against the governing specification for your project.

| Alloy | Si (max) | Fe (max) | Cu (max) | Mn | Mg | Zn (max) | Ti (max) | Al |

|---|---|---|---|---|---|---|---|---|

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | ≥ 99.50 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | ≥ 99.60 |

| 1100 | 0.95 (Si+Fe) | - | 0.20 | 0.05 | - | 0.10 | - | ≥ 99.00 |

| 3003 | 0.60 | 0.70 | 0.05–0.20 | 1.0–1.5 | 0.10 (max) | 0.10 | 0.10 | Remainder |

Choosing mirror coil by end use: a reality-based viewpoint

For lighting reflectors, choose high-purity 1050/1060 in a temper that matches your forming needs, and define reflectance and allowable surface defects clearly. For decorative trim and panels that must survive fabrication, 3003 in H14/H24 is often a strong practical choice, especially when formability and dent resistance matter as much as brightness.

For anodized mirror finishes, consistency is the true luxury. A coil that looks perfect in raw mill finish but anodizes with streaks is not mirror in the customer's eyes. In these cases, prioritize alloy cleanliness, uniform rolling history, and strict degreasing and packaging.

In the end, mirror finish aluminum coil is a material that behaves like a conversation between metallurgy and light. The best coils are the ones where that conversation stays calm from the rolling mill to the final installation-no surprises, no hidden defects, just a controlled reflection that performs as beautifully as it looks.

https://www.al-alloy.com/a/mirror-finish-aluminum-coil-aluminum-alloy.html