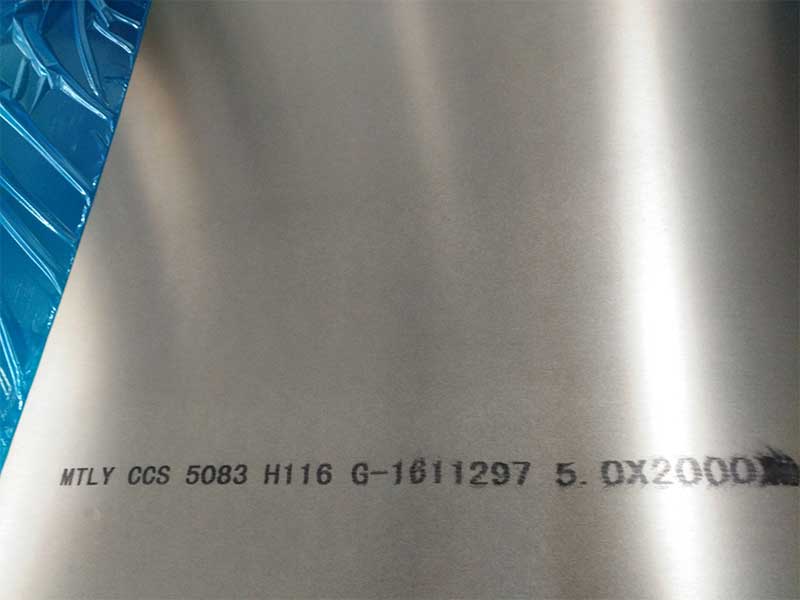

Aluminum marine plate 5083 h116

Aluminum Marine Plate 5083 H116 is a high-strength alloy widely utilized in shipbuilding and offshore applications, owing to its excellent corrosion resistance, especially in marine environments. Designed for superior performance under harsh conditions, these plates meet stringent standards that ensure durability, weldability, and exceptional strength.

Chemical Composition

The 5083 aluminum alloy belongs to the 5xxx series, primarily alloyed with magnesium, which is responsible for its superior corrosion resistance and increased strength. The chemical composition conforms to recognized standards such as ASTM B928 and EN 485-2.

| Element | Typical Range (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

Temper Designation: H116

The H116 temper of the 5083 alloy signals a specific strain-hardened condition along with stabilization heat treatment aimed at enhancing strength while preserving resistance to corrosion. It is particularly designed to resist marine stress corrosion cracking, ensuring aptitude for critical applications on saltwater vessels and structures.

- H116 means the plate is strain-hardened to fairly high strength and then stabilized through a slight heat treatment to relieve residual stresses.

- Offers improved surface finish ensuring it can undergo welding processes without loss of material integrity.

Mechanical Properties

| Property | Metric Value (Typical) | Imperial Equivalent (Typical) |

|---|---|---|

| Tensile Strength | 275 – 350 MPa | 40,000 – 50,800 psi |

| Yield Strength (0.2%) | 145 – 215 MPa | 21,000 – 31,000 psi |

| Elongation at Break | ≥ 12% | ≥ 12% |

| Hardness (Brinell) | ~85 HB | ~85 HB |

| Density | 2.66 g/cm³ | 0.096 lb/in³ |

Implementation Standards and Certifications

- Marine Grade Compliance: Aluminium 5083H116 is certified to meet IMO (International Maritime Organization) standards and ABS (American Bureau of Shipping) classification.

- ASTM Standards: Typically produced in compliance with ASTM B928 or B209.

- EN Standards: May also meet EN 485-2 / EN 573 as required by European clients.

- These strict industry standards ensure material testing frames the quality level acceptable for welded marine structural components including decks, hulls, and superstructures.

Features and Benefits

- Corrosion Resistance: Superior resistance to seawater and industrial chemical environments mitigating oxidation, pitting, and marine growth interferences.

- High Strength-to-Weight Ratio: Enhances overall vessel efficiency by lowering structural weight without sacrificing safety or longevity.

- Excellent Weldability: Fusion, TIG, and MIG welding maintain joint quality; H116 temper protects against distortion and reduces post-welding heat treatment requirements.

- Cold Formability: Ideal grade for rolling, bending, and forming shaped aluminum plates during hull or panel manufacturing.

- Good Finishing Properties: Supports anodizing, painting, and application of other surface protective coatings.

Application Areas

- Shipbuilding: Hull plating, superstructures, decks, and compartments where seawater resilience and structural mutability are mandatory.

- Offshore Platforms: Integral to platform decking, automated skin, flood barriers, and environmental protection where corrosive sea atmospheres dominate.

- Other Marine Structures: Life rafts-forming aluminum, well boats, aluminum barges subjected to salty or brackish water exposure.

- Naval and Commercial Vessels: Craft prioritizing speed, stamina, and long operational availability benefit significantly.

Typical Delivery Conditions and Size Range

- Thickness Range: 3 mm up to 250 mm (customizable current mill practices)

- Widths: Generally pivots between 1000 mm to 2600 mm; larger rolls and sheets contingent upon customer demand

- Lengths: Tailored per industrial demand – flat sheets or standard sizes expected

- Surface Finishes: Mill finish, brushed, polished, or anodized per order specifics

Storage and Handling Recommendations

- Keep in cool, dry conditions with minimal splash or direct contact with seawater until processing.

- Avoid mechanical shock which may induce tin-deformity or cracking, safeguarding its corrosion proof layer.

- Traceable tagging for thickness, temper, casting batch, and QC certificates to maintain material integrity during project lifecycle.

https://www.al-alloy.com/a/aluminum-marine-plate-5083-h116.html