Solar mirror reflective 1100 H14 aluminum coil

Solar Mirror Reflective 1100 H14 Aluminum Coil is a specially manufactured aluminum product designed to offer high precision reflectivity for solar energy panels, lighting, decorative surfaces, and other reflective applications. Utilizing alloy 1100 in H14 temper condition, the coil combines enhanced hardness, superior surface finish, and excellent corrosion resistance, making it an optimal solution for industrial and architectural projects demanding consistent and high reflectivity performance.

Features & Benefits

- Exceptional Reflectivity: Mirror finish surface with high specular reflectance (>90%), optimizing solar energy capture and reflection efficiency.

- High Purity 1100 Alloy: Minimum 99.0% aluminum content ensures excellent corrosion resistance and electrical conductivity.

- H14 Temper Hardness: Cold worked temper offers a perfect balance of strength and flexibility with improved mechanical properties.

- Uniform Surface Quality: Mirror-polished surface with stringent quality controls reduces surface imperfections, improving aesthetics and function.

- Lightweight & Durable: Combines the inherent lightweight advantages of aluminum with higher hardness and fatigue resistance in H14 temper.

- Easy Fabrication: Excellent formability allows cutting, bending, stamping, and rolling without cracking or loss of reflectivity.

- Environmental Sustainability: 100% recyclable aluminum sheet supporting eco-friendly applications.

Chemical Composition (Alloy 1100 — Typical Values %)

| Element | Content (%) |

|---|---|

| Aluminum (Al) | 99.0 Min |

| Copper (Cu) | 0.05 |

| Iron (Fe) | 0.95 |

| Manganese (Mn) | 0.05 |

| Silicon (Si) | 0.95 |

| Zinc (Zn) | 0.10 |

| Titanium (Ti) | 0.03 |

| Others | ≤ 0.15 |

Mechanical Properties (H14 Temper)

| Property | Value | Test Method |

|---|---|---|

| Tensile Strength | 130—145 MPa | ASTM B209 |

| Yield Strength | ≥ 115 MPa | ASTM B209 |

| Elongation | ≥ 3% | ASTM B209 |

| Hardness (Brinell) | 35-50 HB | ASTM E10 |

| Electrical Conductivity | Typically 60% IACS | ASTM B193 |

Note: Exact values may vary slightly depending on coil thickness and processing conditions.

Physical & Surface Characteristics

- Thickness Range: 0.2 mm – 2.0 mm

- Width Range: Typically 200 mm – 1250 mm (can be customized)

- Length: Provided in coil form, customizable pack length

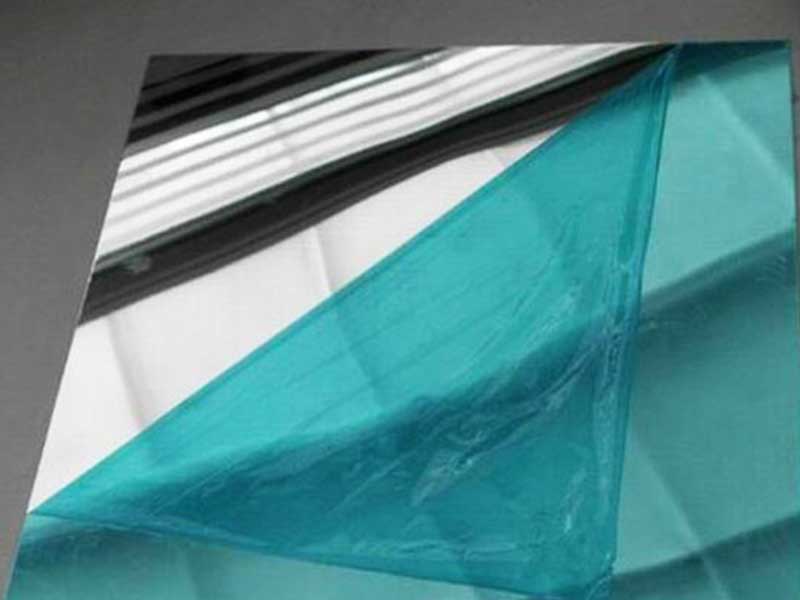

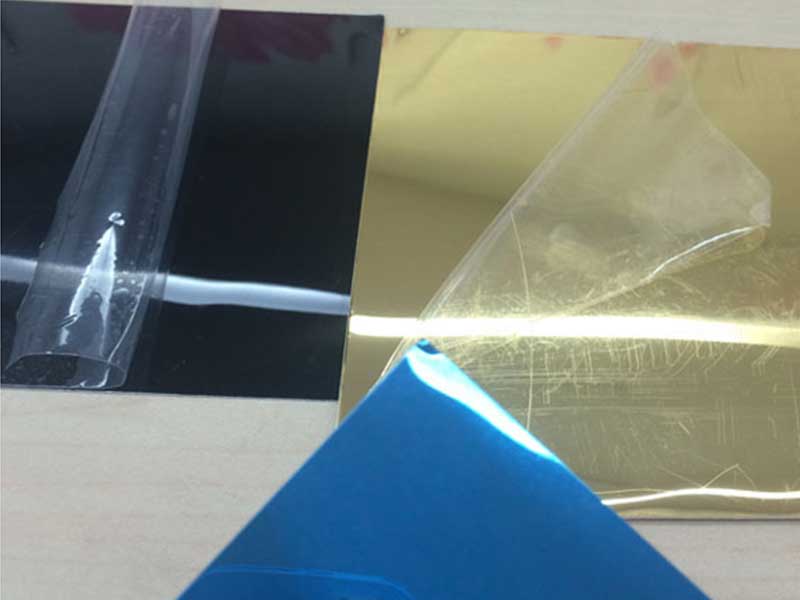

- Surface Finish: Highly polished mirror reflective surface with protective coating option available for portability and anti-oxidation during transportation

- Flatness: Controlled to meet industry flatness tolerances for high-precision fabrication

Implementation Standards & Certifications

- Standards Compliance: Manufactured and tested to meet/exceed ASTM B209, EN 573-3, EN 485-2, and GB/T3190 industrial standards.

- Surface Quality Examination: Certified mirror finish surface per ISO 9001 quality management system.

- RoHS Compliance: Environmentally friendly, lead and mercury-free.

- REACH Certification: Compliant with European chemical regulations.

The 1100 aluminum alloy in H14 temper undergoes strain hardening via cold rolling, creating a partially hard and strain-hardened condition. The term H14 denotes a proprietary term for "strain hardened to half hard":

- Aluminum billet is cast and rolled to the required gauge.

- Cold rolled and controlled to achieve 12–18% elongation reduction.

- Relaxation annealing is avoided to retain cold work strength.

- Causes moderate increase in tensile and yield strength with retained flexibility.

- Hardness and workability reminisce important for precision application surfaces such as solar mirrors.

Applications

- Solar Energy Heliostats & Mirrors: For concentrating solar power reflecting mirrors with high efficiency and durability.

- Lighting Fixtures: Manufacture of reflective light recycling surfaces to enhance light output.

- Architectural Decoration: Indoor/outdoor surface treatments with reflective aesthetics and corrosion resistance.

- Electronic Device Casings: Housing requiring good thermal and electrical performance combined with reflective finishing.

- Printing & Signage Substrates: Mirror-like background for high-impact visuals and back-lit signage.

Handling and Storage Recommendations

- Store the coil in a clean, dry, and ventilated warehouse to prevent moisture fallout and micro-corrosion focus.

- Avoid contact with abrasive or corrosive compounds during transportation or handling.

- Use protective film or packaging when moving post-finishing to ensure surface integrity.

- Design twisting or fabricate under temperature control to maintain the mirror reflective surface quality.

https://www.al-alloy.com/a/solar-mirror-reflective-1100-h14-aluminum-coil.html