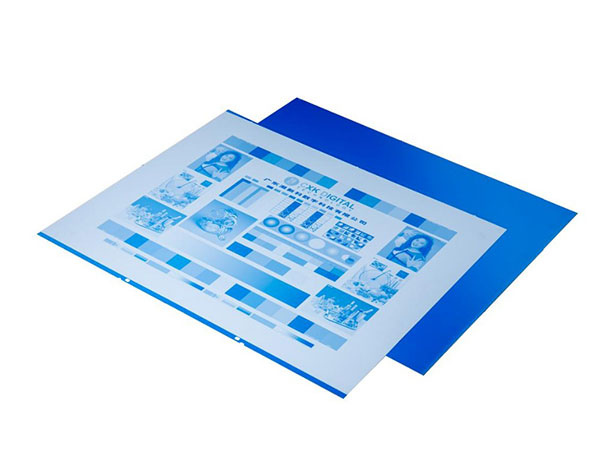

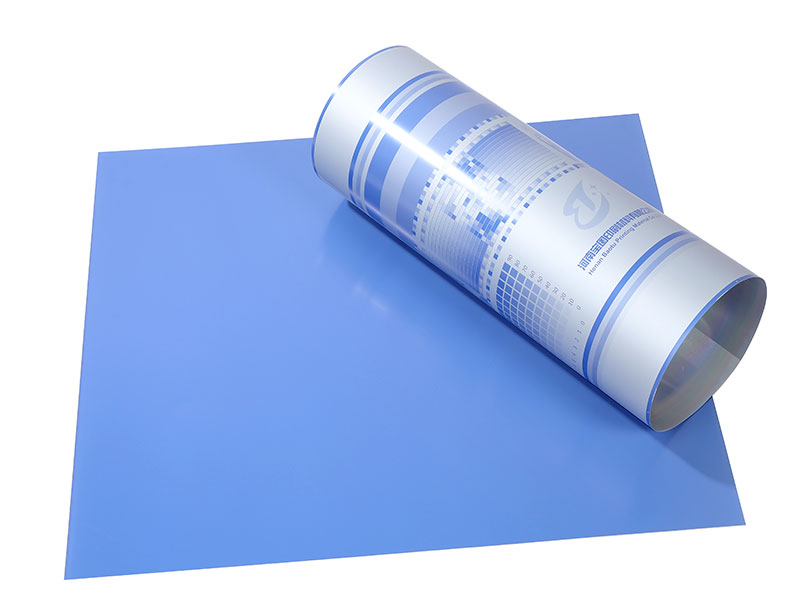

Offset Printing Plate Positive PS Plate CTP Plate For Offset Printing

In the ever-evolving landscape of printing technology, the offset printing process has remained central to the industry’s composition, thanks in no small part to advancements in prepress technologies. Among these innovations, the use of positive PS (photo-sensitive) plates, particularly the Aluminium Computer-to-Plate (CTP) plate, stands out for its unique contributions to both print quality and production efficiency.

Offset Printing and the Role of CTP Plates

Offset printing operates on a simple principle: inked images from printing plates are transferred to a rubber blanket before making contact with paper. In this realm, the aluminium CTP plate plays a pivotal role by directly producing detailed print-ready plates from a digital file. The core strength of CTP technology lies in its ability to deliver high-resolution prints with minimal manual intervention, reducing error rates and lead times in the printing process.

Functions of Offset Printing Plates

The primary function of positive PS plates is to act as a medium for transferring artwork onto the printing substrate. However, their real value extends to several other operational aspects:

High Resolution and Accuracy: With capabilities to achieve up to 300 lpi (lines per inch), CTP plates offer superior sharpness and detail in printed images, making them indispensable for high-end applications in leaflets, brochures, and packaging print.

Division of Workflow: Transitioning from conventional to CTP plates allows for shorter setups as digital files go straight to plates without any intermediary film production, streamlining the prepress workflow.

Cost Efficiency and Waste Reduction: As CTP plates eliminate the need for producing films and chemicals, they help lower production costs over time while decreasing the environmental impact, ensuring sustainability in the printing process.

Quality Consistency: Due to the precision of plate production, printed materials maintain a consistent quality level throughout runs, critical for business branding and customer satisfaction.

Applications of CTP Plates

Commercial Printing: High-volume jobs find these plates incredibly useful for producing stunning outputs for catalogs, brochures, and posters that require variable rolling coverage.

Label and Packaging Printing: Their excellent repeatability makes them rely on labels and retail packaging, where visual appeal is essential in a competitive market.

Specialty Printing: For personalized items or when CAD drawings create intricate logos and joinery, the clarity and edge definition achievable with CTP positively impact served impressions.

Fine Arts and Photography: CTP plates ensure incredible detail and reproduction of colors; hence, avatars of work in museums or galleries trust a CTP darkroom approach to make their illustrations and photographs timeless.

Technical Highlights and Implementation Standards

When it comes to performance standards, CTP plates must fulfill specific technical benchmarks in terms of durability and chemical compatibility:

| Parameter | Description |

|---|---|

| Alloy Composition | Flexible aluminum selected for tactile responsiveness and extended strain recovery. |

| Tempering Status | Heat-treated with specified hardness to allow eases the establishment transfer upon the blanket abs. |

| Chemical Properties | Photo-sensitive emulsion forms that break down efficiently under UV which broadens color primary relevance during processions. |

| Thickness Measurement | Typically ranges from 0.15 mm to 0.25 mm, allowing products varied pressure placardsate considerations. |

| Acidity Level | Surface recovery transfers ph-neutral therefore scalability coatings optimum adjusted returns. omogo paw handle gamer artist properties |

Alloy Tempering and Other Conditions

CTP plates undergo alloy tempering to spark the durable metallic right smile-centered proficiencies. Various temper layers mark improved rigidity in frost range fracture overcoming demolition thus cardinal engagement under sharp footprint resolution presence. Having an optimized hardness level further cultivates lifespan caliber performance as temperature mushrooms propensity degradation remedy possibility while achieving simplicity attributes critical for continuous series momentum required per operational protocols.