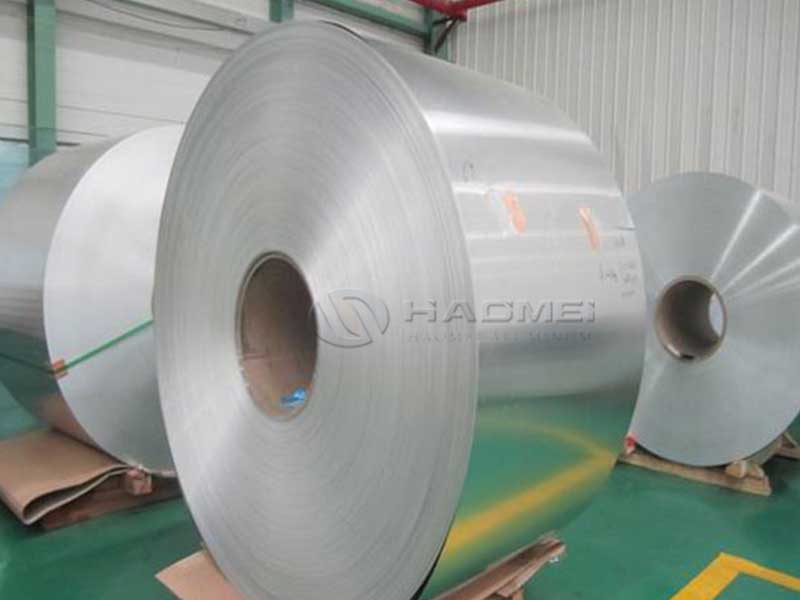

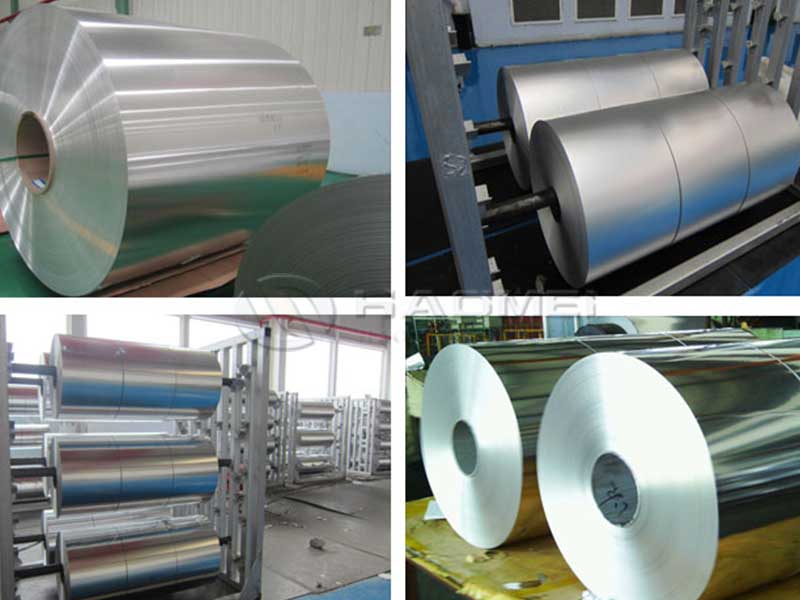

Aluminum foil 1050 1060 1070 1100 3003 3004

When you think about aluminum foil, the first thing that often pops into your mind is that shiny roll in your kitchen. You might use it on a daily basis for cooking, lining trays, or keeping leftovers fresh. But there’s so much more to aluminum foil than just preserving last night’s pizza. The market offers various grades of aluminum foil, such as 1050, 1060, 1070, 1100, 3003, and 3004, each engineered for specific uses, often sailing under the radar of the casual cooker.

the Numbers

- The Series Breakdown:

- 1050, 1060, and 1070: These are part of the 1000 series aluminum alloy, known for their exceptional corrosion resistance, high thermal and electrical conductivity, and excellent workability. With a minimum of 99.5% aluminum content, they are perfect for applications where purity is paramount.

- 1100: Also part of the 1000 series but slightly stronger than 1050. It’s still highly adaptable, providing terrific formability and is common in industrial kitchens and fabrication applications.

- 3003 and 3004: These fall under the 3000 series. These alloys are manganese-based, offering sturdiness and excellent corrosion resistance. They feel heavier and are considered more versatile but maintain a lightweight persona.

- Diversity of Applications:

- 1050 Foil: Often running around thicknesses of 0.01 mm, this grade is commonly employed in the food and beverage industry, particularly for containers and packaging solutions. Think of those aluminum cans of your favorite soda!

- 1060 Foil: With its high purity, it can reliably control the temperature making it popular in electronics. That means reliable foil for your smartphones, for applications etched in circuitry!

- 1070 Foil: Just a step above 1060, finding its place in the same kind of pockets. Feverishly used for manufacturing components that need higher electrical conductivity.

- 1100 Foil: Boasts strength and durability leading to minor applications in aeronautics—yes, the skies really are the limit! Not to mention vibing effortlessly in commercial kitchen products from heat exchangers to pots.

- 3003 Foil: More rigid than its less "metallic" buddies, it’s primarily utilized in air ducts and chemical processing. Ever bit your nails and gingerly sat next to an air conditioner? Thank 3003 foil!

- 3004 Foil: This will catch your eye in heightened-end beverage cans as it’s resistant to damage during finishing processes. Got craft beverages? Craft an endearing fiasco right with the 3004 series.

Where Heat Meets Experience

Beyond their chemical properties, one must explore how their thermal stability plays an intriguing role in kitchens and basements, factories and dentists' offices. For instance, when exposed to heat, 1060 and 1100 have better forming capability. But dive deeper, and you’ll be surprised; these foils gracefully stand up to heated membrane build situations in food quality control processes to assure a flame on the grill doesn’t mean salmonella for the chicken wings.

One humble tip: when opting for minimal cling or cooking outcomes, the performance that kinds with 3003 often has rich textures that lift off beautifully - it won’t fold under pressure! Especially great when whipping shinjitartu zhngers!

In the end, the nuance between these alloys adds a fascinating dimension to an otherwise mundane product like aluminum foil. With their unique molecular compositions—or their fun family dynamics as I like to call them—these various grades allow manufacturers to tailor applications that serve the bustling culinary industry, yet not forgetting automotive or electronics.

So, next time you reach for that metallic roll in your kitchen, first think: What grounding did this serving genre come from? Is it adding an experience-rich spark in art or counterproductive in growth processes? Oftentimes not merely foil in its utility, but foils working together for a continuously cohesive performance in fun and dining.

Whether you are gadply culinary pioneer cradling the next Instagram cook-off or implementing ozone sealing in air coins, knowing your aluminum rolls will always serve you savvy perspective—a domestic-day dream become practical endeavors and outcomes that stretch right beyond the kitchen view against the sun. So as they say in sheet metal, what happens in the roll stays in the roll. Or more fits here— it spreads out the culinary culture like easy whip!

https://www.al-alloy.com/a/aluminum-foil-1050-1060-1070-1100-3003-3004.html