0.3mm 0.4mm 0.5mm Thickness Aluminum Sheet Plate

0.3mm 0.4mm 0.5mm Thickness Aluminum Sheet Plate: Comprehensive Guide and Specifications

Aluminum sheet plates with ultra-thin thicknesses of 0.3mm, 0.4mm, and 0.5mm play an indispensable role in modern manufacturing, where lightweight, corrosion resistance, and superior machinability are critical factors. These thicknesses provide a perfect balance between flexibility and mechanical strength, appealing to industries such as aerospace, electronics, automotive, and packaging.

Product Description

The aluminum sheet plates provided in 0.3mm, 0.4mm, and 0.5mm thicknesses are produced using advanced rolling technologies, ensuring thickness accuracy and uniform mechanical properties across the sheet. Depending on customer requirements and applications, different alloy types and tempers can be selected to tailor the balance of strength, flexibility, and formability.

Working with 0.3mm, 0.4mm, and 0.5mm aluminum sheet plate daily reveals just how delicate a balance there is between material properties and practical application. These thicknesses are incredibly thin; you're practically handling foil, but with the demands of a structural material. The slightest imperfection in the rolling process, a minor scratch during handling, or even a temperature fluctuation during storage can significantly impact the final product's quality. We're constantly refining our procedures to minimize these issues, from optimizing the lubrication in the rolling mill to implementing stricter quality checks before packaging. The challenge is always ensuring consistent gauge, flatness, and surface finish across every sheet, especially given the inherent malleability of such thin aluminum.

Personally, what fascinates me is the sheer versatility of these thin plates. They're not just a raw material; they're the foundation for countless products, from intricate electronic components to decorative elements in consumer goods. Seeing a seemingly insignificant sheet transformed into a complex circuit board or an elegant piece of architectural cladding is incredibly rewarding. However, this versatility also presents unique challenges. The ease with which these plates can be deformed also makes them susceptible to damage during shipping and handling, a constant worry for our logistics team. Ultimately, mastering the production of these incredibly thin aluminum sheets is a testament to both the precision of our machinery and the expertise of our workforce.

Alloy Selection and Chemical Composition

Typically, the following wrought aluminum alloys are preferred for ultra-thin sheet applications:

| Alloy | Main Application | Chemical Composition (%) |

|---|---|---|

| Si | ||

| 1100 | Electrical, Chemical industry | 0.05 |

| 3003 | General metal goods | 0.6 |

| 5005 | Architectural, transport | 0.2 |

| 5052 | Marine structures, automotive | 0.4 |

Note: Composition values represent max permissible limits to guarantee alloy integrity.

Temperature Tempering Conditions

Several temper grades cater to mechanical strength and placing demands on formability:

| Temper Code | Description | Mechanical Properties | Remarks |

|---|---|---|---|

| O | Annealed | Ultimate tensile strength (UTS): 40-55 MPa | Softest temper, high ductility |

| H14 | Strain hardened, partial thickness and stronger | UTS: 130-210 MPa | Higher strength, dimensionally stable |

| H24 | Strain hardened then partially annealed | UTS: 115-195 MPa | Balanced strength and formability |

| H32 | Strain hardened and stabilized | UTS: 135-215 MPa | Corrosion resistant and good formability |

Temper standards follow ASTM B209, ISO 6361, and EN 485.

Mechanical and Physical Properties

| Property | Typical Range | Units |

|---|---|---|

| Thickness Tolerance | ±0.03 (for 0.3-0.5mm range) | mm |

| Density | 2.70 | g/cm³ |

| Tensile Strength (5005-O) | 90-140 | MPa |

| Yield Strength (3003-H14) | 110-160 | MPa |

| Elongation at break | 8 – 25 | % |

| Thermal Conductivity | 150-205 | W/(m·K) |

| Electrical Conductivity | ~50% IACS | % IACS |

Standards and Certifications

Our 0.3mm, 0.4mm, and 0.5mm thick aluminum sheets conform to international manufacturing and control standards providing consistency for critical applications:

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate.

- EN 485-2: Aluminum and aluminum alloys - Sheet, strip and plate — Part 2: Mechanical properties.

- ISO 6361: Wrought aluminum sheet, strip, and plate.

- RoHS Compliance: Restriction of hazardous substances for environmentally responsible production.

Applications

- Electronics & Electrical Casings: Utilizing 0.3mm thickness for lightweight, electrically conductive shielding enclosures.

- Automotive and Aerospace Panels: 0.4mm and 0.5mm sheets improve strength-to-weight ratio and corrosion resistance.

- Architectural Facades and Cladding: Thin plates for cladding and decorative sheet metal applications with excellent formability.

- Packaging Industry: Aluminum sheets for food containers and flexible blinds that guarantee hygienic performance.

- Industrial Channels: Heat exchangers, solar panels, RVs siding benefitting from corrosion resistance and thermal conduction.

Inspection & Quality Control

Stringent inspection protocols including:

- Thickness and flatness measurement.

- Composition validation by optical emission spectroscopy.

- Mechanical testing per ASTM/ISO.

- Surface finish visual inspection for blemishes or oxidation.

- Coil winding and slitting precision checks.

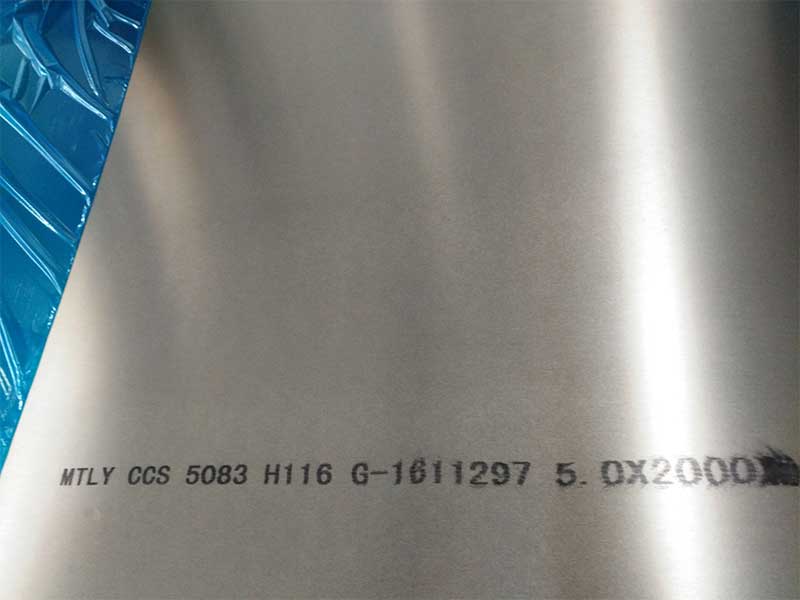

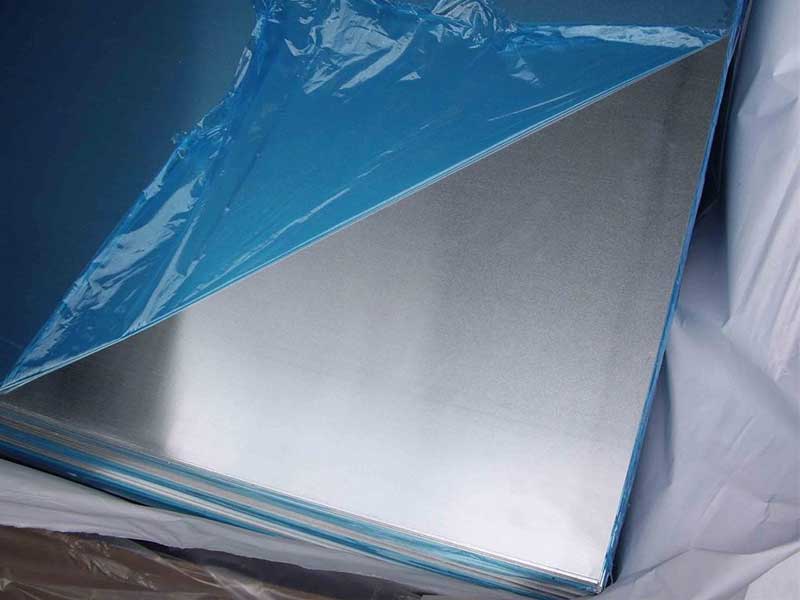

Packaging & Delivery

Sheets are usually cut by shearing or slitting with protective film or oil coating tailored to avoid scratches or oxidation during transit. Package shipped in pallets covered by waterproof plastic for bath delivery.

https://www.al-alloy.com/a/03mm-04mm-05mm-thickness-aluminum-sheet-plate.html