3003 8011-H22 Aluminum Foil for Foil

3003 8011-H22 Aluminum Foil for Foil: The Unsung Hero of Everyday Essentials

When we think about aluminum foil, most of us just imagine the shiny sheets used in kitchens to wrap leftovers or line baking trays. But behind this everyday convenience lies a nuanced world of aluminum alloys designed for specific purposes, tailored to meet various needs in industries and households alike.

What’s So Special About 3003 and 8011-H22?

Both 3003 and 8011 are aluminum alloys commonly used to make aluminum foil, but each carries a distinct fingerprint in terms of composition and performance.

3003 Alloy: It’s an aluminum-manganese alloy, prized for its excellent corrosion resistance, good formability, and moderate strength. The manganese adds a bit of toughness, allowing the foil to be flexible yet sturdy enough for a wide range of uses.

8011 Alloy: This one is aluminum with added iron and silicon. It’s designed specifically to optimize properties crucial for foil production, especially when the foil has to be rolled out thin without tearing while retaining its strength.

Now, add the H22 temper designation—which essentially means the foil has been strain-hardened and partially annealed—balancing ductility and strength. This tempers the foil to an ideal mix: easy enough to handle and fold, yet rigid enough not to crumble unexpectedly when you press any ingredients against it. It’s a Goldilocks temper.

The Functional Edge: Why Use 3003 or 8011-H22 Foil?

The beauty of these foils lies in their balance:

Durability Without Bulk: Unlike pure aluminum foil which can be prone to tearing, 3003 provides extra robustness thanks to its manganese addition. This gives your foil a bit more chew without being too tough to fold or seal neat packages.

Excellent Barrier Properties: 8011-H22 aluminum foil is particularly noted for its superior resistance to light, moisture, and gases. This keeps food items fresher for longer, making it a popular choice in food packaging industries.

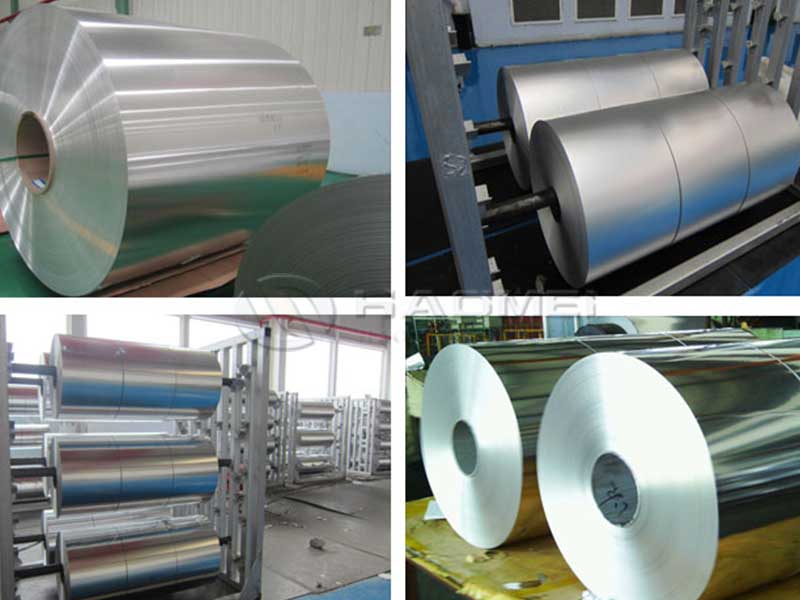

Good Workability: Both alloys lend themselves well to various methods of fabrication—rolling, stamping, and shaping. This is vital for how aluminum foil gets turned into the familiar rolls and sheets stocked in every pantry or industrial setting.

Real-World Applications: More Than Just Kitchen Staples

Here’s where things get interesting. Aluminum foil isn’t just about leftovers:

Food Packaging: Using 8011-H22 foil helps extend shelf life of snacks, bakery products, and even frozen foods by serving as a protective skin against contaminants.

Pharmaceuticals: Blister packs for pills often use foil made from these alloys, combining a barrier against moisture and protection from physical damage along the supply chain.

Industrial Uses: The heat resistance and reflectivity of 3003 foil makes it perfect in thermal insulation materials, reflecting radiant heat back and maintaining temperature consistency within things like ductwork and cooling systems.

Household Uses: Beyond simply wrapping a juicy steak, avid grillers rely on 3003 alloy foil because it withstands slightly higher cooking temperatures and resists sticking better than standard foil.

Distinctive Technical Insights Without Jargon Overload

Most aluminum foil specifications get bogged down with complicated numbers and metal jargon, but taking a straightforward look: 3003 and 8011-H22 foils provide what all the consumer or manufacturer really wants—performance. A foil that’s tough yet pliable, resists unwanted leaks of moisture or air, and keeps product integrity intact.

In short:

- Aluminum Alloy Content: High purity metals blended to add torsional strength.

- Temper (H22): Ensures readiness for end-user flexibility without fragile brittleness.

- Thickness & Gauge: Common thickness ranges from 0.006mm to 0.02mm—not too thick, not paper-thin fragile.

Bottom Line

Next time you peel back a piece of foil in your kitchen, or chew a wrapped candy with a shiny foil wrapper, remember the unsung engineering in those seemingly simple sheets. 3003 and 8011-H22 aluminum alloys integrate strength, manufacturability, and packaging expertise to keep your food fresh, your cooking smooth, and a diverse range of industries humming behind the scenes.

Discover the unique functions and everyday applications of 3003 and 8011-H22 aluminum foil. Learn how these versatile alloys combine strength, flexibility, and protection to elevate kitchen and industrial uses alike.

https://www.al-alloy.com/a/3003-8011-h22-aluminum-foil-for-foil.html