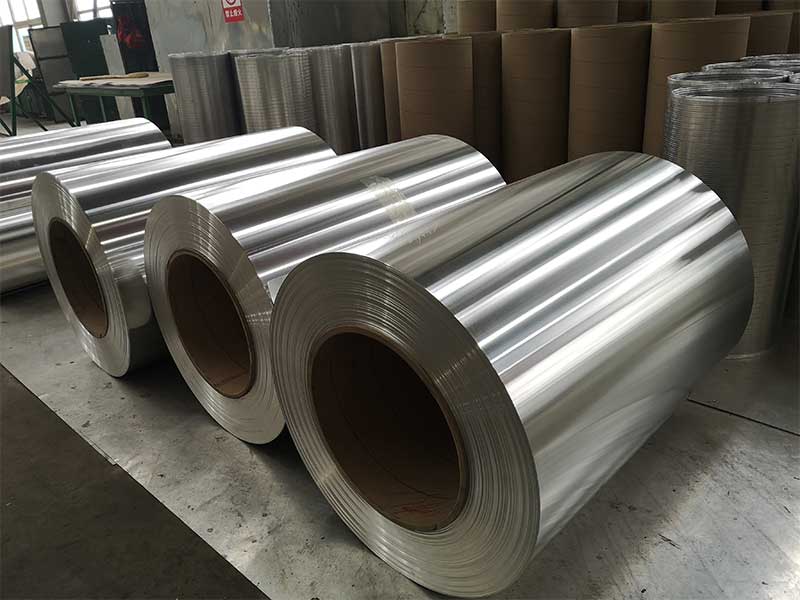

Prepainted aluminum coil 1100,5052,1060,3003,3004

Prepainted Aluminum Coil 1100, 5052, 1060, 3003, 3004: Features and Applications

Prepainted aluminum coil is a versatile building and manufacturing material designed to combine the inherent advantages of aluminum with durable, decorative coatings.

Overview

Prepainted aluminum coil consists of aluminum substrates coated with organic paint layers on one or both surfaces. The aluminum coils deduce the core benefits:

- Corrosion resistance

- Light weighting

- High weatherability

- Design versatility with diverse colors and finishes

Selecting suitable alloys allows tuning physical and chemical performance per requirements such as formability, strength, or corrosion resistance.

Alloy Summaries and Properties

| Alloy Grade | Main Magnesium Content (%) | Typical Properties | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Corrosion Resistance |

|---|---|---|---|---|---|---|

| 1100 | ≤ 0.05 | Excellent corrosion resistance; highly formable; soft and low strength | 35 – 50 | 60 – 90 | 35 – 45 | Excellent in atmospheric environments |

| 5052 | 2.2 – 2.8 | High strength among non-heat-treatable alloys; excellent marine corrosion resistance; good weldability | 193 – 240 | 228 – 283 | 10 – 20 | Superior; ideal for saline/marine use |

| 1060 | ≥ 99.6 (almost pure Al) | Great ductility and surface finish; industrial & architectural polished surfaces | 35 – 50 | 70 – 110 | 28 – 40 | High, but lowers if oxidized or painted |

| 3003 | ~1.2% - 1.5% manganese | Moderate strength, excellent corrosion resistance, good formability, and moderate workability | 70 – 110 | 130 – 160 | 20 – 25 | Good in various environments |

| 3004 | 1.0 – 1.5% manganese; small Cu addition | Improved strength vs 3003; medium corrosion resistance; typical choice in roofing and siding | 140 – 200 | 160 – 220 | 10 – 15 | Slightly less than 3003, still very good |

Chemical Composition (Typical per Alloy)

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) | Others (%) |

|---|---|---|---|---|---|---|---|---|

| 1100 | 0.95 max | 0.95 max | 0.05 max | 0.05 max | 0.05 max | 0.10 max | 0.03 max | Balance Al |

| 5052 | 0.25 max | 0.40 max | 0.10 max | 0.10 max | 2.2-2.8 | 0.10 max | 0.03 max | Balance Al |

| 1060 | 0.25 max | 0.35 max | 0.05 max | 0.05 max | 0.03 max | 0.10 max | 0.03 max | Balance Al |

| 3003 | 0.6 max | 0.7 max | 0.05 max | 1.0-1.5 | 0.10 max | 0.10 max | 0.20 max | Balance Al |

| 3004 | 0.7 max | 0.7 max | 0.05 max | 1.0-1.5 | 0.10 max | 0.10 max | 0.20 max | Balance Al |

Features of Prepainted Aluminum Coil:

Superior Aesthetic AppealThe organic coating systems, typically PE (polyester), SMP (silicone modified polyester), PVDF (polyvinylidene fluoride), enable high-quality finish with brilliant sheen and color retention under various climatological exposures.

Excellent Corrosion and Weather ResistanceAluminum's inherent resistance paired with coatings allows CPS (coil prepainting system) components to weather wind, rain, UV light, and pollution without degradation.

Lightweight and High StrengthAlloys like 5052 and 3004 offer a lightweight alternative with impact and abrasion resistance.

Outstanding Formability and WorkabilitySelect alloys provide excellent press and roll forming performance, critical in architectural and industrial facades.

Cost-efficiencyCompared with stainless steel and other metals, prepainted aluminum offers a good balance between performance and price.

Environment Friendly and RecyclableAluminum coils are 100% recyclable saving energy comparing to virgin aluminum production, and coatings adhere strictly to global VOC and hazardous material standards.

Applications by Alloy

Alloy 1100 Prepainted Coil

Due to its exceptional formability and corrosion resistance, 1100 aluminum prepainted coils are mainly used for interior decorative panels, control panels, false ceilings, ductwork, camping goods, and lighting fixtures.

Alloy 5052 Prepainted Coil

With high mechanical strength and excellent marine environment corrosion resistance, 5052 is widely adopted in outdoor architectural panels, storefronts, canopies, and signage. It is also popular for vehicle parts, shipbuilding, marine applications, and cold storage rooms.

Alloy 1060 Prepainted Coil

As almost pure aluminum, 1060 coil offers superior conductivity and extreme corrosion resistance. It suits food and beverage packaging, electrical applications, reflective material, advertising panel substrates, and electronic chassis.

Alloy 3003 Prepainted Coil

3003’s moderate strength and improved formability compared to 1100 along with excellent corrosion resistance make it ideal for kitchen appliances, roof gutters, rainwater pipes, siding, flooring profiles, and wraps.

Alloy 3004 Prepainted Coil

For increased strength and superior weather ability, 3004 is preferred in roofing, siding, rainwater systems, mobile homes, dumpster body panels, and metal furniture.

Conclusion

Selecting the right aluminum alloy in a prepainted coil form grants processors and manufacturers an optimum balance of strength, corrosion resistance, and appearance fit for many modern industrial and architectural solutions.

| Alloy Grade | Best Use Cases | Benefit |

|---|---|---|

| 1100 | Interior decorative panels, ceiling, HVAC duct | Workability and corrosion resistance |

| 5052 | Marine equipment, industrial facades, signage | Strength and marine corrosion defense |

| 1060 | Food packaging, reflective materials | Purity and surface finish |

| 3003 | Roof gutters, appliances, siding | Affordable, medium strength/ easy to form |

| 3004 | Roofing, siding, outdoor panels | Medium strength, weather resistance |

For enquiries on custom coating colors, thickness, alloy treatments, or any application-specific requirements for prepainted aluminum coils in these alloys, please contact our specialists for tailored solutions and quotation.

Haomei Aluminum CO., LTD., Inc. remains at the forefront of producing premium prepainted aluminum coil products that meet worldwide regulations in material integrity, CREW (coating resistance, environmental wear) capability, and sustainability regard.

https://www.al-alloy.com/a/prepainted-aluminum-coil-11005052106030033004.html