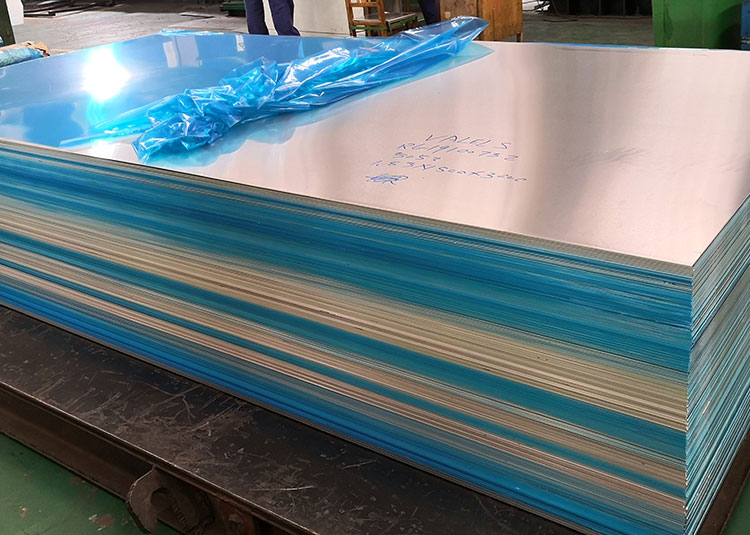

10mm 8mm 6mm Marine Aluminium Sheet

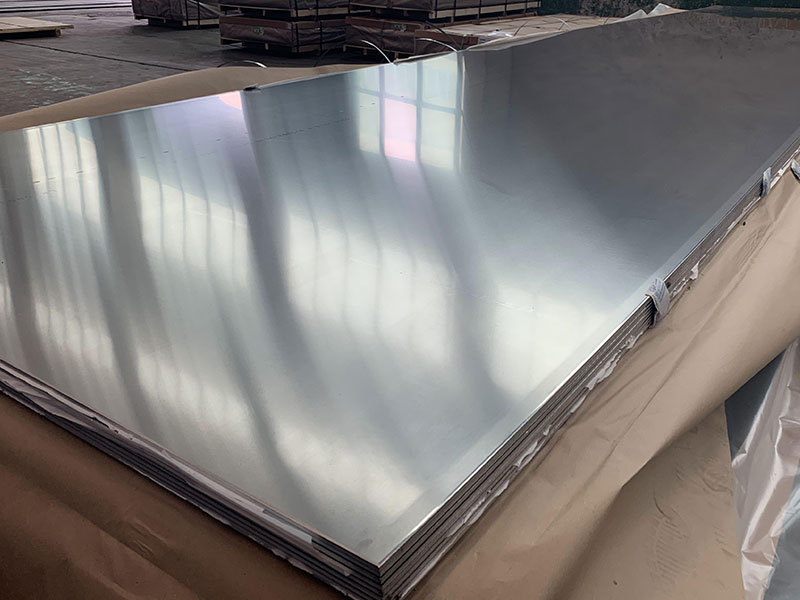

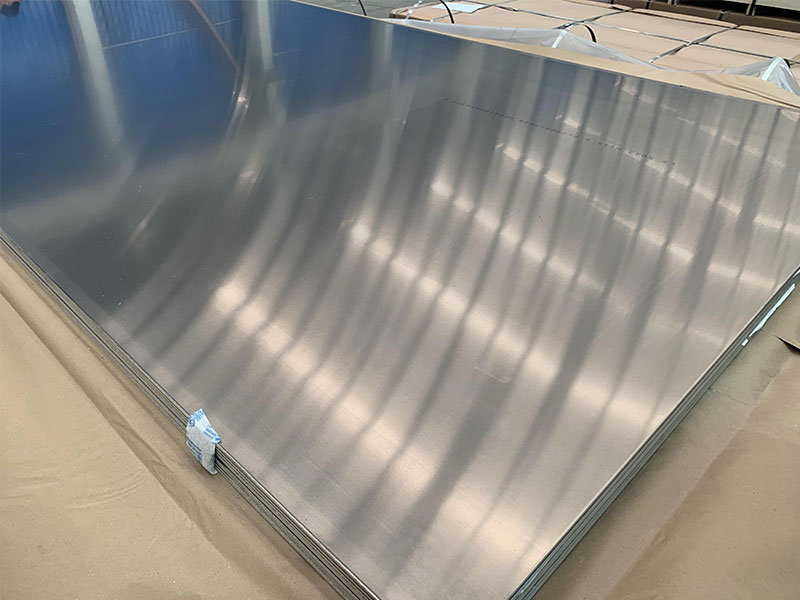

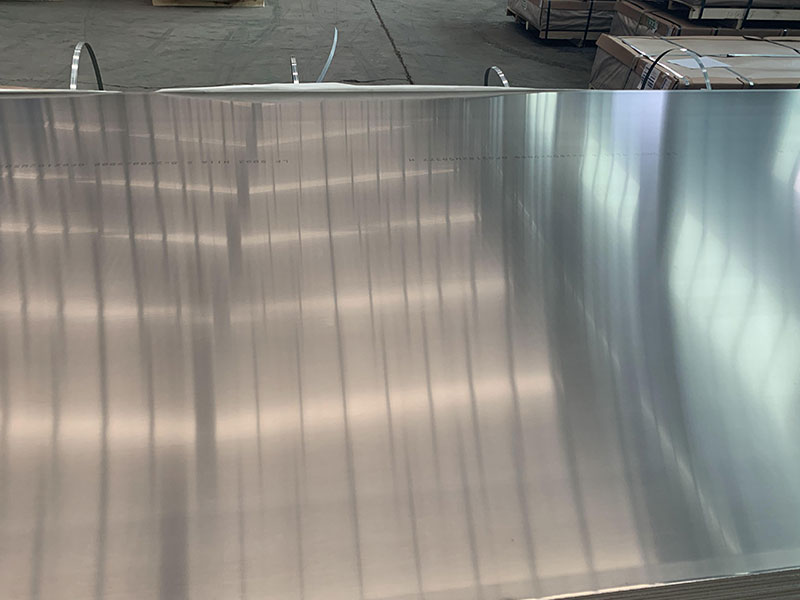

Marine aluminium sheets have revolutionized the shipbuilding and marine engineering sectors due to their outstanding combination of strength, weight, and corrosion resistance. Among these, the 10mm, 8mm, and 6mm marine aluminium sheets is know as versatile options tailored to specific structural and functional demands in maritime environments.

The Unique Functions of Marine Aluminium Sheets

Marine aluminium sheets are primarily designed to withstand harsh marine conditions — salty air, moisture, and mechanical stress from waves and impacts. Their core functions include:

Corrosion Resistance: Marine aluminium sheets, especially those from the 5xxx series, inherently resist corrosion caused by saltwater exposure. This makes them indispensable in ship hulls, decks, and offshore applications.

Lightweight Structural Integrity: Aluminium sheets with thicknesses of 10mm, 8mm, and 6mm provide an optimum balance between strength and weight saving which is crucial for fuel efficiency and maneuverability in marine vessels.

Formability and Weldability: These sheets come in varying gauges that allow efficient forming either through rolling or bending while maintaining excellent weldability critical for joining complex ship structures.

Thickness Matters: 10mm vs. 8mm vs. 6mm Marine Aluminium Sheets

While all three thicknesses come from similar alloys, the differences in use highlight their application specificity.

10mm Marine Aluminium Sheets: Used predominantly in primary structural applications such as hull plating, bulkheads, and frames where high tensile strength (around 290-330 MPa yield strength) withstands mechanical and hydrodynamic stresses. Their robust thickness brings enhanced blocking resistance and vibration damping, vital for cargo ships and passenger liners.

8mm Sheets: Represent a balance of moderate strength and weight, frequently found in deckhouses, secondary structural parts, and intermediate ship bulkheads. A thickness of 8mm provides easier fabrication while maintaining corrosion resistance critical for layered assembly in ships and offshore platforms.

6mm Sheets: Generally applied in superstructure cladding, interior paneling, and protective coverings that require less mechanical load capacity but equally vital corrosion resistance and lightweight characteristics. They facilitate intricate shaping, bending, and easier welding on aluminium boats and smaller marine vessels.

Technical Parameters & Implementation Standards

Typically, marine aluminium sheets conform to internationally recognized shipbuilding regulations and standards such as:

| Parameter | Typical Specification |

|---|---|

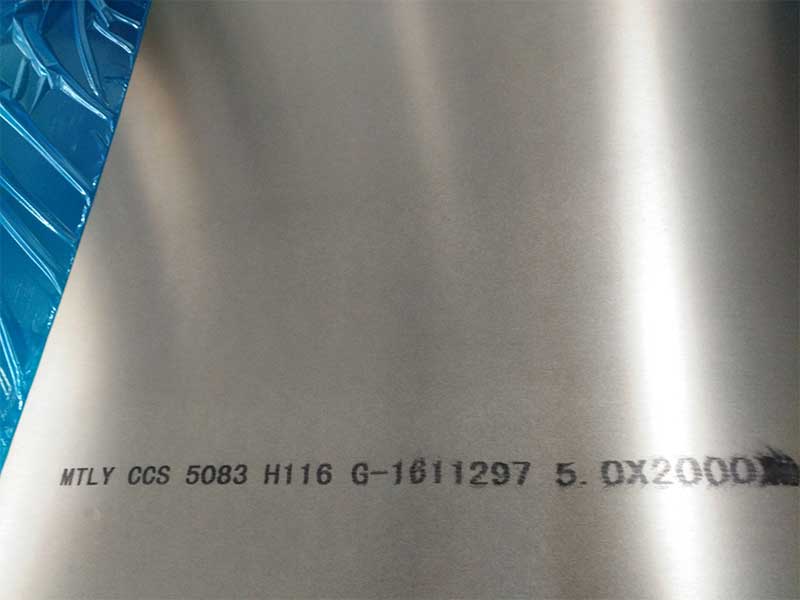

| Alloy system | 5083-H116 / 5005 / 5454 |

| Thickness range | 6mm, 8mm, 10mm |

| Width range | Up to 2500mm |

| Length range | Custom cut length up to 12 meters |

| Yield strength (σ0.2) | 215 - 330 MPa (dependant on alloy temper) |

| Tensile strength (σu) | 275 - 350 MPa |

| Elongation (A%) | ≥ 12% |

| Hardness (Brinell) | Approx. 70-90 HB depending on thickness |

| Corrosion resistance | Excellent in marine environments |

The marine grade aluminium 5083-H116 alloy typically boasts superior corrosion and mechanical properties, catered to shipbuilding. The “H116” temper represents enhanced resistance to exfoliation corrosion, vital in marine usage.

Alloy Tempering and Chemical Properties

The marine aluminium sheets commonly used in 6-10mm thickness belong to non-heat-treatable alloys like 5083 and 5005. Their strengthening mechanism stems from solid solution strengthening rather than precipitation hardening.

| Element | Alloy 5083 Max Content (%) |

|---|---|

| Magnesium (Mg) | 4.0 - 4.9% |

| Manganese (Mn) | 0.4 - 1.0% |

| Chromium (Cr) | 0.05 - 0.25% |

| Iron (Fe) | ≤ 0.4% |

| Silicon (Si) | ≤ 0.4% |

| Zinc (Zn) | ≤ 0.25% |

| Copper (Cu) | ≤ 0.1% |

| Titanium (Ti) | ≤ 0.15% |

| Aluminium (Al) | Balance |

- Magnesium: This is primarily responsible for corrosion resistance and strength, ensuring that thicker sheets (10mm) hold up in heavy-duty applications.

- Chromium: Provides precipitation-hardening resistance even under severe marine exposure.

- Manganese and others: Work synergistically for enhancing toughness and hardening.

Tempering such as H116 is done to improve exfoliation and stress corrosion cracking resistance, render better toughness without loss of ductility, and prevent cracking likelihood under cyclic marine conditions.

Real-World Applications Coverage

- Ship & Boat Hulls: The absolute reliability of 10mm sheets here keeps maritime vessels safe against impact stresses and salt erosion.

- Deck & Bulkhead Construction: 8mm sheets are prevalent in these intermediate power zones, providing ease in assembly and relinquishing unnecessary additional weight.

- Superstructures and Interior Fittings: 6mm sheets serve aesthetics and protective purposes in vessel cabins and cantilever covers.

- Offshore Platforms: These sections depend on strategic combinations of 6mm - 10mm sheets conferring adaptability in diverse load zones and corrosion risk categories.

The selection of 10mm, 8mm, or 6mm marine aluminium sheets does not simply rest on thickness but deeply integrates alloy chemistry, tempering practice, mechanical demands, fabrication feasibility, and the harshness of the maritime environment faced. The interplay of these factors enhances structural integrity, reliability, and longevity of modern marine architectures.

Whether reinforcing the skeleton of a purebred ocean-going tanker or melding the inner framework of recreational yachts, the distinct role of each thickness amplifies cost-efficiency and design sophistication in marine aluminium engineering. This synergy of metal science and engineering ensures sustainable, safer seas and vessels navigating treacherous waters with optimal structural confidence.

Interested in premium marine aluminium sheets tailored to your vessel’s exact structural needs? Contact us to discover Specifications, Supply Options, or Technical Support leveraging cutting-edge marine aluminium technology.

https://www.al-alloy.com/a/10mm-8mm-6mm-marine-aluminium-sheet.html