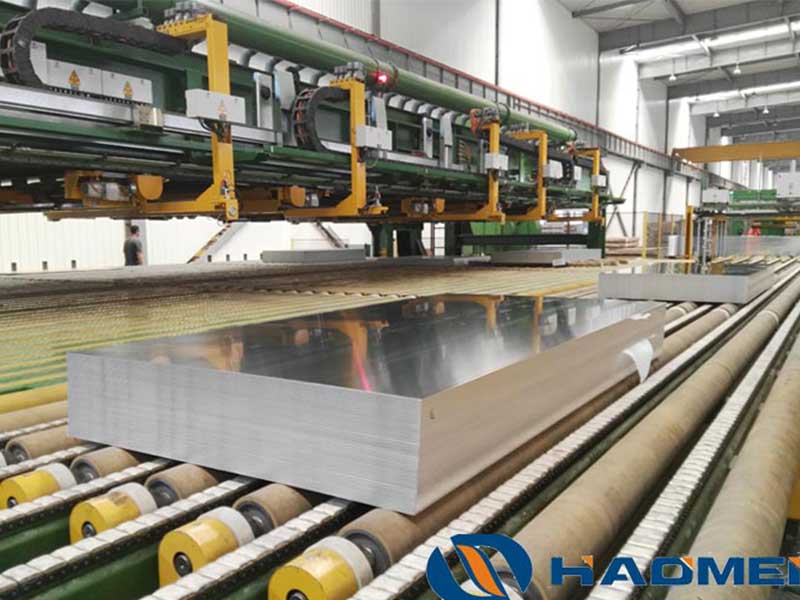

6082 t6 aluminum sheet

6082 T6 Aluminum Sheet: The Unsung Hero of Structural Innovation

When we think of aluminum alloys, names like 6061 or 7075 often steal the limelight. Yet, tucked comfortably between these two giants lies the 6082 T6 aluminum sheet—a material whose nuanced strengths and distinctive qualities make it an unsung hero in structural and engineering applications.

the Basics: What Is 6082 T6 Aluminum?

At a glance, 6082 aluminum is part of the 6xxx series, which means it’s primarily alloyed with magnesium and silicon. These elements combine to give the sheet a commendable balance of strength, corrosion resistance, and machinability. The “T6” temper designation refers to a specific heat treatment—solution heat treated and artificially aged—that optimizes its mechanical properties.

But beyond these basics lies a story of engineering finesse. The chemistry of 6082 T6 allows it to hold structural integrity even under harsher environments than some of its 6xxx siblings. This makes it a preferred choice in sectors such as construction, marine, and transport.

A Unique External Perspective: Why Designers and Manufacturers Prefer 6082 T6

Imagine you're an engineer tasked with designing an outdoor architectural feature—say, a bridge component or a decorative cladding piece. Your primary considerations are strength, weight, corrosion resistance, and ease of fabrication. Here the 6082 T6 aluminum sheet shines admirably.

-

Strength Without Compromise: With tensile strengths reaching up to approximately 290 MPa and good elongation, 6082 T6 offers reliable load-bearing capability. It strikes a sweet spot between rigidity and flexibility, allowing components to withstand daily wear and periodic stress surges.

-

Resistance to the Elements: Thanks to its magnesium and silicon composition, 6082 provides superior resistance against corrosion. This means reduced maintenance cycles, critical for outdoor installations exposed to rain, salt spray, or changing temperatures.

-

User-Friendly Fabrication: Whether it’s welding, cutting, or bending, 6082 T6 excels. Unlike some higher strength alloys that prove temperamental during manufacturing, 6082’s versatility lets designers experiment without fear of cracking or deformation.

Beyond Raw Performance: Environmental Friendliness and Cost Efficiency

In today’s world, sustainability and fiscal responsibility guide almost all purchasing decisions. The 6082 T6 aluminum sheet strikes again by being:

-

Highly Recyclable: Aluminum alloys, including 6082, benefit from a “closed-loop” recycling process, reducing the environmental footprint compared to many other metals.

-

Cost-Effective Material: While not as cheap as pure aluminum, the combination of performance and durability often leads to longer service life, thus lowering the total cost of ownership. This makes it attractive in industries where budget meets long-term reliability.

The Niche Applications That Make a Difference

One might think 6082 T6 is just another degree of aluminum alloy—but its correct application can redefine outcomes. Specialized sectors including:

-

Automotive: Frames and parts optimized for weight saving without sacrificing safety.

-

Rail and Marine: Structural elements enduring stress, vibrations, and corrosive conditions for years.

-

Renewable Energy: Mounting systems for solar panels demanding strength and weather resistance.

These application nuances offer a unique outlook on how specific material selections serve broader technological and economic objectives.

Final Thoughts: Encouraging a Shift in Perspective

The world of aluminum alloys is vast and complex, sometimes overwhelming even for seasoned professionals. Yet, by stepping back and viewing options like 6082 T6 aluminum sheet through a wide-angle lens—considering not only chemical properties but also fabrication skillset, sustainability, and cost—we gain new respect for this often underrated material.

In a landscape crowded with options, the 6082 T6 aluminum sheet offers a compelling combination of traits ensuring that infrastructure, vehicles, and consumer products maintain integrity and reliability while easing manufacturing challenges.