8mm Thick Aluminum Sheet

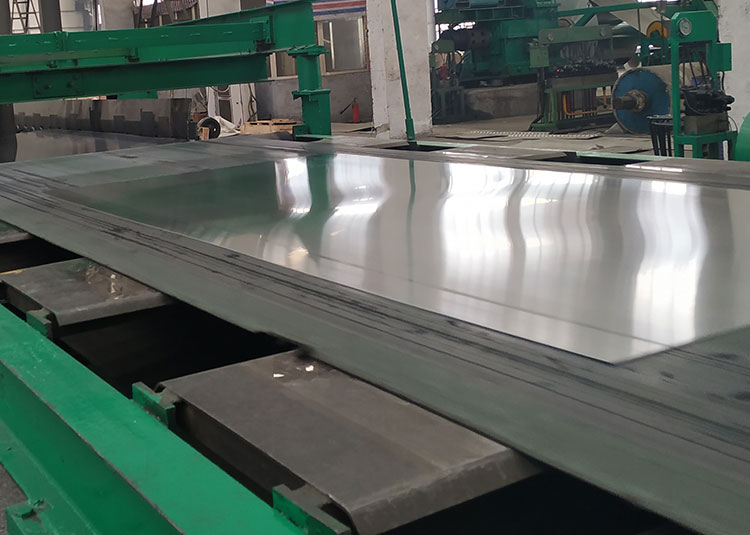

8mm thick aluminum sheets represent a crucial segment in various industrial applications, offering an effective balance of strength, weight, and formability. Whether utilized in aerospace, automotive, construction, or manufacturing sectors, these sheets fulfill stringent performance requirements while providing excellent durability and flexibility.

An 8mm thick aluminum sheet belongs to the category of medium to heavy gauge materials within the aluminum sheet range. This thickness allows the sheet to possess robust mechanical properties without significant compromise on the material's ease of fabrication, such as cutting, bending, or welding.

Alloy Types

Aluminum sheets are typically classified by their alloy series, which determine their material characteristics. The most relevant alloys available in 8mm thickness include:

| Alloy Series | Common Alloys (8mm) | Characteristics | Typical Applications |

|---|---|---|---|

| 1xxx (Pure Al) | 1050, 1060 | Excellent corrosion resistance, high conductivity, low strength | Electrical components, packaging |

| 3xxx (Mn Alloys) | 3003, 3004 | Good corrosion resistance, fair strength, excellent formability | Roofing, siding, general sheet metal |

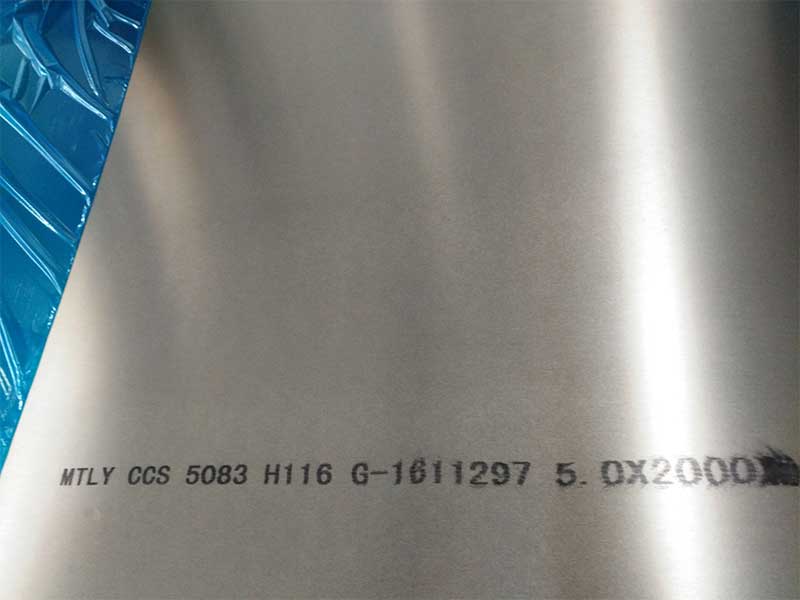

| 5xxx (Mg Alloys) | 5052, 5083, 5005 | High strength, excellent corrosion resistance in marine environments | Marine structures, pressure vessels |

| 6xxx (Mg + Si) | 6061, 6082 | Good mechanical properties, medium strength, good corrosion resistance | Structural framing, transport |

| 7xxx (Zn Alloys) | 7075 (less common in thick sheet) | Very high strength, less corrosion resistance | Aerospace, military applications |

For an 8mm thickness, 5xxx and 6xxx series alloys are most common due to their excellent strength-to-weight ratio and corrosion resistance.

Temper Conditions

The temper condition influences material hardness, strength, and ductility. Commonly supplied tempers for 8mm aluminum sheets include:

- O (Annealed): Fully annealed condition offering maximum ductility, easier to form.

- H1x (Strain Hardened): Partial hardening by cold work (e.g., H12, H14); good strength with limited tolerance on elongation.

- H3x (Strain Hardened and Stabilized): Stored or "stabilized" condition to retain mechanical properties under temperature effects.

- T4 (Solution Heat Treated and Naturally Aged): Moderate strength, improved corrosion resistance, good formability.

- T6 (Solution Heat Treated and Artificially Aged): Peak strength condition, reduced ductility but excellent mechanical performance at room temperature.

Choosing the right temper depends on the requirement of the application in terms of mechanical strength versus formability.

Mechanical and Chemical Properties

Below is a typical property table for a standard 8mm 5052-H32 aluminum sheet:

| Property | Value | Test Standard |

|---|---|---|

| Chemical Composition (%) | ||

| Aluminum (Al) | Balance | |

| Magnesium (Mg) | 2.2 – 2.8 | ASTM B209 |

| Chromium (Cr) | 0.15 – 0.35 | ASTM B209 |

| Manganese (Mn) | ≤ 0.1 | ASTM B209 |

| Iron (Fe) | ≤ 0.4 | ASTM B209 |

| Silicon (Si) | ≤ 0.25 | ASTM B209 |

| Mechanical Properties | ||

| Tensile Strength (MPa) | 200 – 250 | ASTM E8 / EN 485-2 |

| Yield Strength (MPa) | 110 – 140 | ASTM E8 / EN 485-2 |

| Elongation (%) | ≥ 10 | ASTM E8 / EN 485-2 |

| Hardness (HB) | ~60 | Brinell Hardness |

| Density (g/cm³) | 2.68 |

Note: Properties vary depending on alloy and temper.

Implementation Standards

Our 8mm aluminum sheets comply with international quality and metallurgical standards to fit diverse global needs.

- ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- EN 485-2 - Aluminum and aluminum alloys; sheet, strip, and plate; mechanical properties

- AMS 4017 - Heat treated aluminum alloy plate, sheet, and strip

- AA (Aluminum Association) alloy codes

Applications

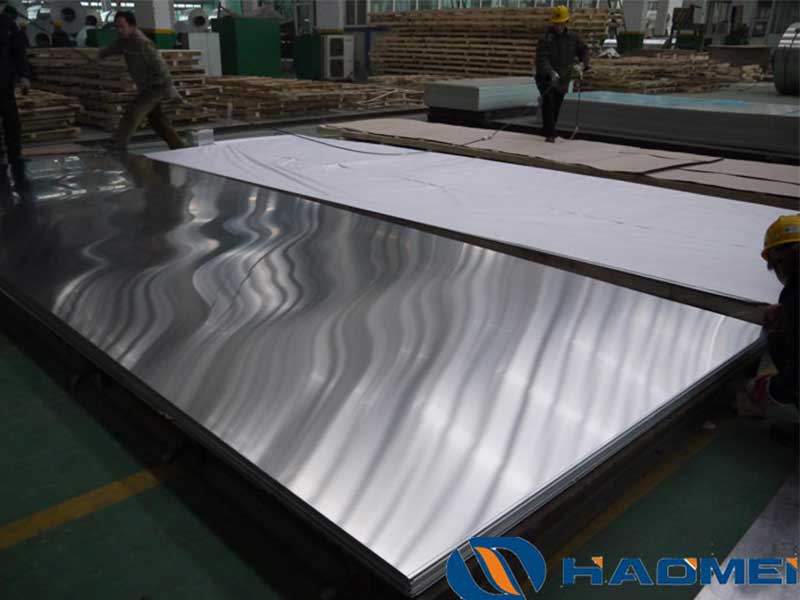

Due to their thickness and reliable mechanical performance, 8mm aluminum sheets suit applications such as:

- Structural Components: Load-bearing frameworks, automotive chassis parts, industrial machinery baseplates.

- Marine Industry: Hulls, bulkheads in boats using 5xxx alloy due to saltwater resistance properties.

- Transportation: Trailer walls, truck bulkheads, and containers.

- Building and Construction: Cladding, roofing, facade panels, elevator walls requiring durability and corrosion resistance.

- Manufacturing: Tooling baseplates, protective shields, machine parts.

Fabrication Notes

- Cutting: Can be processed by laser cutting, water jet, or mechanical shearing depending on tolerances.

- Welding: Compatible with TIG, MIG welding methods with recommended filler materials consistent with shop welding procedures.

- Surface Treatment: Anodizing or powder coating can be applied for further corrosion protection or aesthetics.