2.5 mm aluminum sheet

A 2.5 mm aluminum sheet is a practical "sweet-spot" thickness: rigid enough to hold shape and resist denting in many real-world assemblies, yet thin enough to remain lightweight, formable, and cost-efficient. It is widely used across transportation, building & construction, enclosures, signage, marine components, and general fabrication, where designers need a balance of strength, corrosion resistance, and manufacturability.

Why 2.5 mm thickness is popular

At 2.5 mm, aluminum sheet sits in a versatile range for both structural and cosmetic uses:

- Good stiffness-to-weight ratio: noticeably stiffer than 1–2 mm sheet, with only a modest weight increase.

- Better dent resistance: improved resistance to handling damage, vibration, and localized impacts.

- Manufacturing flexibility: supports bending, rolling, laser cutting, punching, and welding depending on alloy/temper.

- Consistent flatness and fit-up: easier to maintain tolerances for panels, lids, covers, and fabricated frames.

Common alloys and tempers (selection guide)

Different alloys are chosen based on corrosion resistance, strength, weldability, and forming behavior. The table below summarizes the most common choices for 2.5 mm sheet.

Alloy selection quick guide

| Alloy (Series) | Typical Tempers | Strength Traits | Corrosion Resistance | Weldability | Best Use Cases |

|---|---|---|---|---|---|

| 1050 / 1060 (1xxx) | O, H12, H14 | Low strength, very high ductility | Excellent | Good | Reflectors, insulation cladding, cosmetic panels |

| 3003 (3xxx) | O, H14 | Moderate strength, excellent formability | Excellent | Very good | Roofing, gutters, enclosures, general forming |

| 5052 (5xxx) | H32, H34 | Higher strength than 3003, good fatigue | Excellent (marine-grade) | Excellent | Marine panels, vehicle body parts, fuel-related parts |

| 5083 (5xxx) | H111, H116 | High strength, strong in marine environments | Excellent (marine) | Very good | Shipbuilding, heavy-duty panels, ramps |

| 6061 (6xxx) | T6, T4 | High strength, machinable | Good | Good (procedure-sensitive) | Brackets, structural panels, frames (often T6) |

Practical tip: If you need tight bending radii and deep forming, choose 3003-O/3003-H14 or 5052-H32. For marine exposure, favor 5052 or 5083. For high strength and machined features, consider 6061 (often with welding considerations).

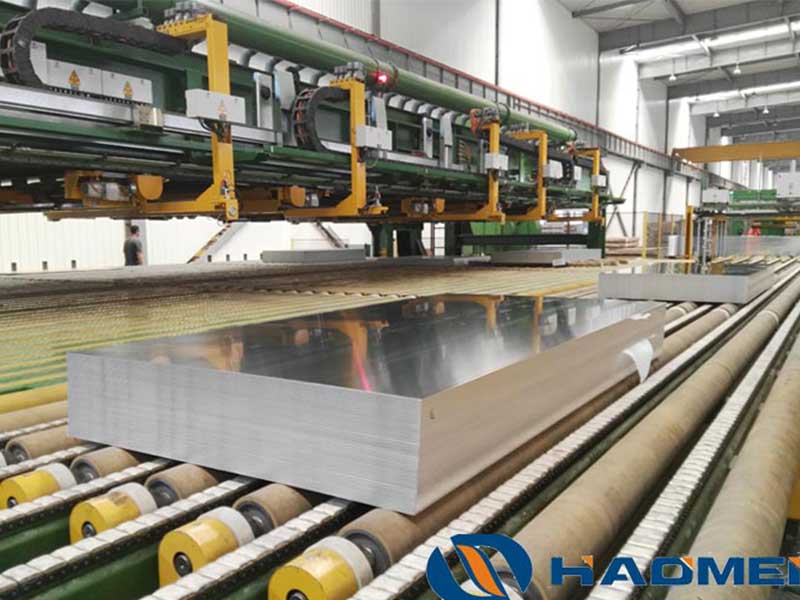

Technical specifications (typical supply scope)

A 2.5 mm aluminum sheet is supplied in various widths and lengths, and may come with protective film for cosmetic applications.

Dimensional and delivery specifications

| Item | Typical Range / Option |

|---|---|

| Thickness | 2.5 mm (tolerance depends on standard and supplier capability) |

| Width | 1000–2000 mm (common: 1000 / 1220 / 1250 / 1500 mm) |

| Length | 2000–6000 mm (common: 2000 / 2440 / 2500 / 3000 mm) |

| Edge | Mill edge or slit edge |

| Surface finish | Mill finish, brushed, embossed, anodizing-quality, painted/pre-coated |

| Flatness control | Standard or improved leveling (for CNC/laser and panel work) |

| Protective film | Optional (single or double-sided) |

| Standards (typical) | ASTM B209 / EN 485 / JIS H4000 (depending on region) |

Density and weight (helps estimate freight and handling)

| Parameter | Value |

|---|---|

| Density of aluminum | ~2.70 g/cm³ |

| Weight per m² at 2.5 mm | ~6.75 kg/m² |

Typical chemical composition (by alloy family)

Chemical composition varies by standard and supplier melt practice. The table below provides representative compositions for widely used sheet alloys.

Chemical composition (typical, wt.%)

| Alloy | Al | Mg | Mn | Si | Fe | Cu | Cr | Zn |

|---|---|---|---|---|---|---|---|---|

| 1050 | ≥99.5 | - | ≤0.05 | ≤0.25 | ≤0.40 | ≤0.05 | - | ≤0.05 |

| 3003 | Bal. | - | 1.0–1.5 | ≤0.6 | ≤0.7 | 0.05–0.20 | - | ≤0.10 |

| 5052 | Bal. | 2.2–2.8 | ≤0.10 | ≤0.25 | ≤0.40 | ≤0.10 | 0.15–0.35 | ≤0.10 |

| 6061 | Bal. | 0.8–1.2 | ≤0.15 | 0.4–0.8 | ≤0.7 | 0.15–0.40 | 0.04–0.35 | ≤0.25 |

| 5083 | Bal. | 4.0–4.9 | 0.4–1.0 | ≤0.40 | ≤0.40 | ≤0.10 | 0.05–0.25 | ≤0.25 |

Mechanical performance (what you can expect)

Mechanical properties depend strongly on temper (O, H32, T6, etc.) and processing route. The following values are typical ranges used for engineering selection.

Mechanical properties (typical ranges)

| Alloy & Temper (typical) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Notes |

|---|---|---|---|---|

| 1050-H14 | 95–120 | 75–105 | 3–10 | Great conductivity and corrosion resistance; low strength |

| 3003-H14 | 130–180 | 110–150 | 4–12 | Excellent forming; common for panels and enclosures |

| 5052-H32 | 210–260 | 130–200 | 7–16 | Strong, marine-capable, good fatigue behavior |

| 6061-T6 | 260–320 | 240–280 | 8–12 | High strength; best for structural parts; bend radius needs care |

| 5083-H116/H111 | 275–350 | 200–260 | 10–16 | Marine/high-load sheet; strong corrosion resistance in seawater |

Engineering note: For bending and forming, elongation and temper often matter more than peak tensile strength. If your part requires tight bends, choose a softer temper or form first and heat-treat later where applicable.

product features and benefits

1) Corrosion resistance that reduces lifecycle cost

Aluminum naturally forms a protective oxide layer. Alloys like 5052/5083 provide excellent resistance in humid or marine environments, minimizing paint failures and rust-related maintenance compared with carbon steel.

2) High strength-to-weight for transport and mobile equipment

A 2.5 mm sheet offers meaningful stiffness while staying lightweight. This helps reduce fuel consumption in vehicles, improves payload efficiency, and makes manual installation easier for panels and covers.

3) Fabrication-friendly: cut, form, weld, finish

Depending on alloy:

- Laser/plasma/waterjet cutting produces accurate profiles.

- Press brake forming supports brackets, channels, and enclosures.

- Welding is reliable for 5xxx alloys; 6xxx welding can be done with correct filler and post-weld strength considerations.

- Finishing options include anodizing, powder coating, PVDF coating, brushing, and embossing.

4) Aesthetic flexibility

For signage, architectural panels, appliances, and decorative trims, 2.5 mm sheet can be specified with:

- brushed or satin finishes,

- color-coated surfaces,

- protective films to prevent scratches during installation.

Typical applications (where 2.5 mm excels)

| Industry | Application Examples | Recommended Alloys |

|---|---|---|

| Construction | Curtain wall backing sheets, soffits, roofing accessories, flashing | 3003, 5052, pre-coated options |

| Transportation | Trailer side panels, bus/coach interior panels, protective covers | 5052, 5083, 6061 |

| Marine | Deck plates, partitions, equipment panels | 5052, 5083 |

| Industrial & Electrical | Machine guards, control cabinets, instrument enclosures | 3003, 5052 |

| Signage & Display | Sign boards, frames, structural backing plates | 3003, 1050 (for reflectivity) |

| General fabrication | Brackets, panels, covers, jigs | 5052, 6061 |

How to specify the right 2.5 mm aluminum sheet (buyer checklist)

To avoid mismatches and rework, specify these items clearly:

| Specification Item | What to Decide |

|---|---|

| Alloy & temper | Based on forming, strength, corrosion needs (e.g., 5052-H32) |

| Surface | Mill finish vs brushed vs coated vs anodizing-quality |

| Flatness | Standard vs leveled for CNC/laser and large panels |

| Protective film | Needed for cosmetic surfaces and shipping |

| Tolerances & standard | ASTM/EN/JIS requirement; inspection method |

| End-use environment | Indoor, outdoor, marine, chemical exposure |

| Fabrication process | Bend radius, welding plan, fasteners, coating compatibility |

A 2.5 mm aluminum sheet delivers a reliable combination of strength, corrosion resistance, low weight, and fabrication flexibility. With the right alloy selection-3003 for forming, 5052/5083 for corrosion and marine duty, 6061 for high strength-it becomes an efficient material choice for both industrial production and custom fabrication.