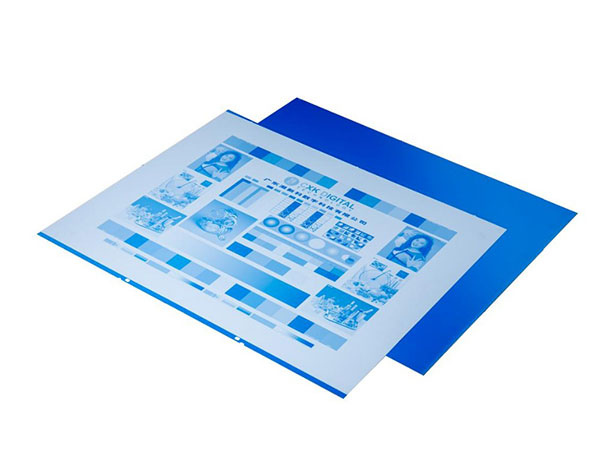

PS Offset Printing Plate Positive CTCP Plate Aluminum Thermal UV CTP Plates

PS Offset Printing Plates, Positive CTCP plates, and aluminum-based Thermal/UV CTP plates are engineered for one goal: stable, repeatable printing with fast platemaking and reliable press performance. Built on precision-grained and anodized aluminum, these plates combine strong image reproduction, long run length, and excellent ink–water balance-making them a practical choice for commercial, packaging, and publication printing.

For plate buyers, the value is simple: consistent coating quality, controlled aluminum metallurgy, and tight dimensional stability translate into fewer press stops, less waste, and predictable dot gain. Whether you are exposing via conventional PS workflows, CTcP (violet) systems, or thermal/UV CTP engines, the aluminum substrate is the foundation that governs durability, resolution, and processing latitude.

These plates are manufactured from high-quality aluminum coil (typical series AA1xxx/3xxx) processed through electrolytic graining, anodizing, and surface sealing. Depending on plate type, a photosensitive coating is applied for positive PS, positive CTcP, or thermal/UV CTP imaging. The plate surface is designed to hold a clean latent image, accept fountain solution uniformly, and maintain press stability over long runs.

Features (Customer-Focused)

| Feature | What it means in production | Customer benefit |

|---|---|---|

| Precision grained & anodized aluminum | Uniform micro-porous oxide layer | Stable ink–water balance, reduced scumming |

| High dimensional stability | Controlled alloy, flatness, and gauge | Accurate registration, fewer remakes |

| Strong adhesion between coating and anodic film | Optimized sealing and coating chemistry | Better wear resistance, reduced image loss |

| Wide processing latitude | Developer tolerance and stable coating response | Easier operation, consistent results across shifts |

| Clean background and sharp dot formation | Controlled roughness and hydrophilicity | High resolution, smooth gradients |

| Compatibility across workflows | PS / CTcP (violet) / Thermal / UV CTP | Flexible line setup, easier plate sourcing |

Typical Applications

| Application segment | Printing characteristics | Recommended plate choice |

|---|---|---|

| Commercial printing | Fast turnaround, varied paper stocks | Positive PS or CTcP; thermal for higher stability |

| Publication printing | Long runs, consistent tone | Thermal CTP for run length and dot stability |

| Packaging (paper-based) | Dense solids, fine text, spot colors | Thermal or UV CTP for durability |

| Labels and inserts | Tight registration, crisp small fonts | CTcP or thermal depending on device |

| General offset jobbing | Mixed workloads and short/medium runs | PS or CTcP for cost-effective output |

Aluminum Substrate: Alloy & Temper Conditions

The plate base typically uses high-purity aluminum or Al-Mn alloy for strength and forming stability. Temper selection supports flatness, coil handling, and consistent graining response.

| Item | Common options | Why it matters |

|---|---|---|

| Alloy family | AA1050, AA1060, AA1070, AA3003 (typical) | Purity supports uniform anodizing; Mn improves strength |

| Temper | H18 / H19 (common), customized on request | Balances hardness, flatness, and post-processing stability |

| Grain structure | Electrolytic graining | Defines water retention and imaging uniformity |

| Anodic film | Sulfuric anodizing (typical) | Improves abrasion resistance and hydrophilicity |

Chemical Composition (Typical Aluminum Plate Base)

Actual composition depends on chosen alloy and customer requirements. The following table reflects commonly used plate-base alloys in the industry.

| Element (wt.%) | AA1050 (typ.) | AA1060 (typ.) | AA3003 (typ.) |

|---|---|---|---|

| Al | ≥ 99.50 | ≥ 99.60 | Balance |

| Si | ≤ 0.25 | ≤ 0.25 | ≤ 0.60 |

| Fe | ≤ 0.40 | ≤ 0.35 | ≤ 0.70 |

| Cu | ≤ 0.05 | ≤ 0.05 | 0.05–0.20 |

| Mn | ≤ 0.05 | ≤ 0.05 | 1.0–1.5 |

| Mg | ≤ 0.05 | ≤ 0.05 | ≤ 0.10 |

| Zn | ≤ 0.07 | ≤ 0.07 | ≤ 0.10 |

| Ti | ≤ 0.05 | ≤ 0.05 | ≤ 0.10 |

Note: Values shown are typical industry ranges; mill certificates and coil-specific data should be used for acceptance criteria.

Technical Specifications (Core Numerical Data)

The following specifications are typical for aluminum CTP/CTcP/PS plate bases and finished plates. Final parameters can be tailored to equipment, chemistry, and run-length targets.

| Parameter | Typical range / option | Test focus |

|---|---|---|

| Plate thickness | 0.15–0.40 mm (common: 0.15 / 0.20 / 0.30) | Press cylinder fit, stiffness |

| Width | 100–1600 mm | Device compatibility |

| Length | 100–4000 mm | Device/press format |

| Thickness tolerance | ±0.005–0.010 mm | Stable packing and pressure |

| Surface roughness (Ra) | 0.30–0.60 µm (typical) | Water carrying capacity |

| Anodic layer weight | 1.0–3.0 g/m² (typical) | Wear resistance, background cleanliness |

| Coating weight | 1.0–3.0 g/m² (by plate type) | Sensitivity and durability |

| Flatness | Controlled by coil leveling | Registration and transport stability |

| Surface cleanliness | Low residual contamination | Reduces coating defects and pinholes |

Imaging & Plate Type Selection (PS / Positive CTcP / Thermal / UV)

Different imaging technologies change how the coating reacts to exposure and development, while the aluminum base ensures mechanical and chemical stability.

| Plate type | Imaging source | Typical strengths | Typical use case |

|---|---|---|---|

| PS positive plate | UV exposure via conventional platesetter/frame | Mature workflow, cost-effective | Small–mid shops, conventional exposure lines |

| Positive CTcP (violet) | 405 nm laser | Efficient imaging, good speed | Commercial printing with violet CTP |

| Thermal CTP plate | 830 nm laser | High stability, strong process tolerance | High-end commercial, publication, packaging |

| UV CTP plate | 355/405 nm depending on system | High resolution, versatile | Fine text, mixed substrates, modern UV devices |

Performance Highlights on Press

| Performance attribute | What to expect | Why it matters |

|---|---|---|

| Dot reproduction | Clean highlights, stable mid-tones | Better color control and smoother gradients |

| Ink receptivity | Quick ink-up, consistent density | Faster make-ready, less waste |

| Water balance | Stable hydrophilic background | Reduced scumming and emulsification |

| Abrasion resistance | Durable oxide + strong coating adhesion | Longer run length, fewer plate changes |

| Chemical resistance | Designed for common developers and fountain solutions | Fewer background stains, longer plate life |

Processing & Handling Notes (Practical Guidance)

| Step | Best practice | Result |

|---|---|---|

| Storage | Cool, dry environment; avoid direct sunlight | Preserves coating activity and flatness |

| Handling | Gloves recommended; avoid scratching | Prevents fingerprints and image defects |

| Development | Use matched chemistry; monitor conductivity/pH | Stable sensitivity and clean background |

| Gumming/protection | Apply clean gum; avoid contamination | Better plate preservation before press |

| Press start | Confirm fountain settings and roller condition | Faster stabilization and consistent print |

Ordering Options (Common Customer Requirements)

| Option | Typical choices |

|---|---|

| Plate format | Coil, sheet, punched, pre-bent |

| Surface | Standard grained/anodized; customized roughness |

| Alloy/temper | AA1050/1060/1070/3003; H18/H19 options |

| Packaging | Anti-moisture wrap, corner protection, palletized |

| Quality documents | Mill certificate, inspection report, traceability by coil/lot |

PS Offset Printing Plate Positive CTCP Plate Aluminum Thermal UV CTP Plates are high-performance offset printing plates built on precision-grained and anodized aluminum substrates, delivering stable ink–water balance, sharp dot reproduction, and reliable run length. Available for PS, positive CTcP (violet), thermal CTP, and UV CTP workflows, these plates support commercial, publication, and packaging printing with consistent quality, tight thickness control, and customizable alloy/temper options. Ideal for printers seeking fast make-ready, low waste, and dependable press stability across a wide range of formats and imaging systems.