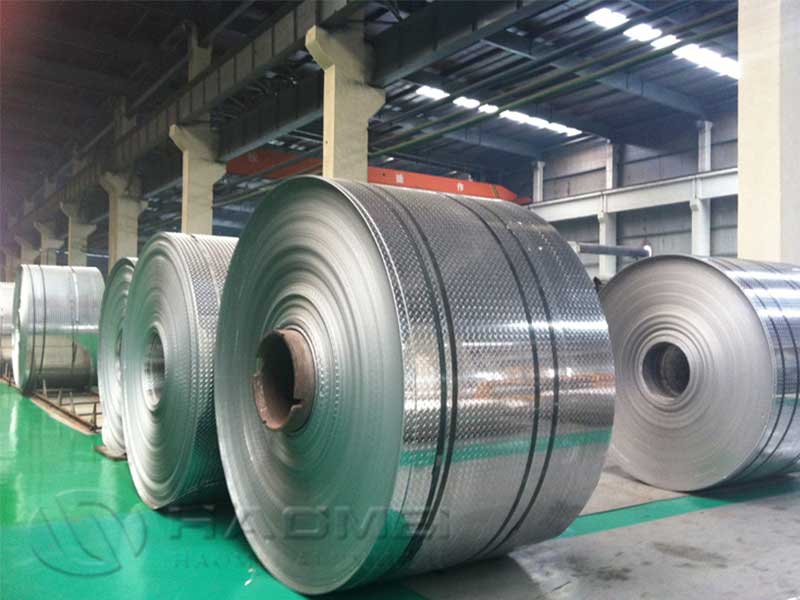

Aluminium tread sheet

Aluminium tread sheets, also known as embossed aluminium sheets or checker plates, have increasingly become staples in various industries, serving both functional and aesthetic purposes. These specialized plates, recognized for their raised diamond or bar patterns, inadvertently transform surfaces into functional territories—where design meets practicality, embodying strength and versatility.

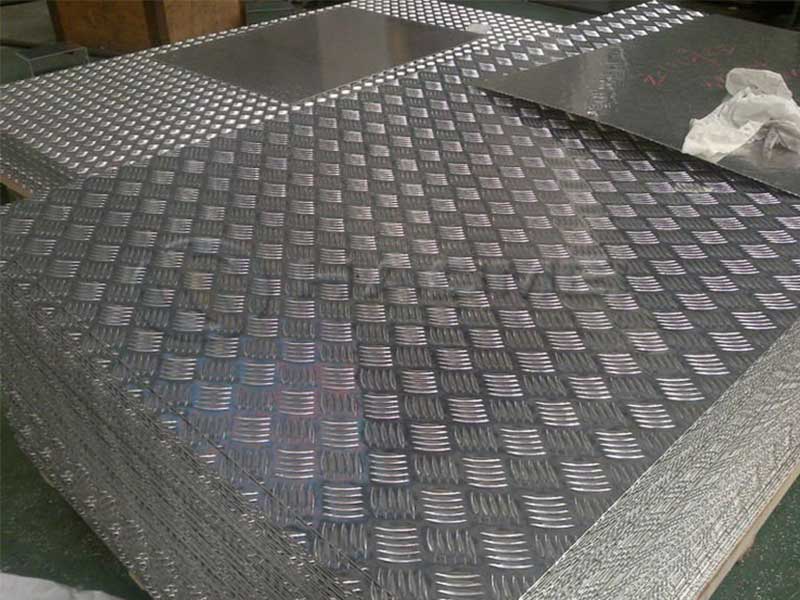

Features of Aluminium Tread Sheets

1. Surface Texture

The hallmark feature of aluminium tread sheets is the textured surface, typically engineered in a diamond or linear pattern. This unique surface enhances friction, providing crucial slip resistance which is paramount in high-traction applications. The patterns not only dissipate liquids and debris but also enhance aesthetics—allowing for integration into design-forward settings.

2. Strength-to-Weight Ratio

Aluminium is celebrated for its lightweight nature without compromising on strength. Most tread sheets are produced using high-grade alloys, such as 6061 and 5052 aluminum. These alloys meet the stringent requirement of high impact strength, corrosion resistance, and durability. Coupling excellent mechanical properties and weight advantages helps enhance performance in various applications ranging from construction to automotive.

3. Corrosion Resistance

Aluminium's natural oxide layer provides exceptional resistance to corrosion, enhancing the lifespan of panels in challenging environments. Whether exposed to water, chemicals, or diverse weather conditions, aluminium tread sheets assure minimal maintenance and long-term applications. Intrinsically, this corrosion resistance is linked to the alloys' chemical composition which often includes elements like magnesium and silicon.

4. Customizability

To further augment their versatility, aluminium tread sheets can be easily customized to fit varying thicknesses, finishes, and sizes. Standards like ASTM B221 outline specifications allowing manufacturers minimum and maximum measurements pertaining to various thicknesses in an effort to suit specific use cases without requisite compromises.

Applications of Aluminium Tread Sheets

1. Construction Sector

Given their durability and weight characteristics, aluminium tread sheets carve out applications in temporary and permanent structures. They serve as load-bearing panels, flooring materials, or wall coverings. Whether employed for tight warehouse spaces or large-scale airplane hangar entrances, their ability to support heavy usage without sustaining damage is invaluable in architectural applications.

2. Automotive Industry

Tread sheets find varied utilizations within the automotive industry. They are commonly utilized for truck beds, trailers, and vehicle running boards, enhancing lifespan and promoting safety through non-slip surfaces. Endowed with thermal and chemical resistance coupled with easy workability, tinkers often fancy aluminium tread sheets for kreative modifications, safety upgrades, or customizable aesthetic enhancements.

3. Flooring Solutions

Aluminium tread sheets act as fundamental flooring materials in both industrial and commercial facilities where slip hazards remain a concern, such as machineries, factories, while sharpening ergonomics. Their minimal maintenance requirements align them economically with the constraints of original capital investments, safe-keeping workplace conditions both for human safety and operational efficacy.

4. Decorative Elements in Art and Design

Beyond functionality, aluminium tread sheets forge the bridge into contemporary decor through their unique surfaces transforming unadorned metal into prospects of artful ventilation panels, architectural claddings, and settings remarkably influenced toward patina effects or unique surfaces capturing light diligently against contours.

Technical insights and Specifications

Manufacturers lean heavily on established standards when sourcing or creating aluminium tread sheets to interpret the balance in properties comprehensively. Recognized standards include the aforementioned ASTM B221, ISO 9001 quality standards, aligning device practices to performance-relevant practices.

Chemical Properties Table

The chemistry of commonly used aluminium alloys for tread sheets is essential in application for a balance on functionality:

| Alloy | Si (%) | Fe (%) | Cu (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Mn (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|---|

| 5052 | 0.25 | 0.4 | 0.1 | 2.2 | 0.15 | 0.25 | 0.15 | 0.8 | Balance |

| 6061 | 0.4 | 0.7 | 0.15 | 1.0 | 0.15 | 0.25 | 0.15 | 0.15 | Balance |

- The values enclosed symbolize general compositions and may vary slightly based on versions and finishing techniques siginificant in treat sheets happy within capacities serving tungsten compelling neutrality.*

In a realm where aesthetics marries resilience, aluminium tread sheets stand out, ushered by durability attributes, along with visual allure, proliferating trends across various spheres and making them quintessential in stakes owned within our domestic infrastructures plus diverse expressions into mechanizing elements of our daily interactions. Choosing the right aluminium tread sheet transcends simple selection—an impactful-driven choice yielding wider implications based upon the adorned applications sought. Certainly, they compel moves toward sustainable made design dilemmas within tomorrow’s context that revel arithmetic in collage and function.