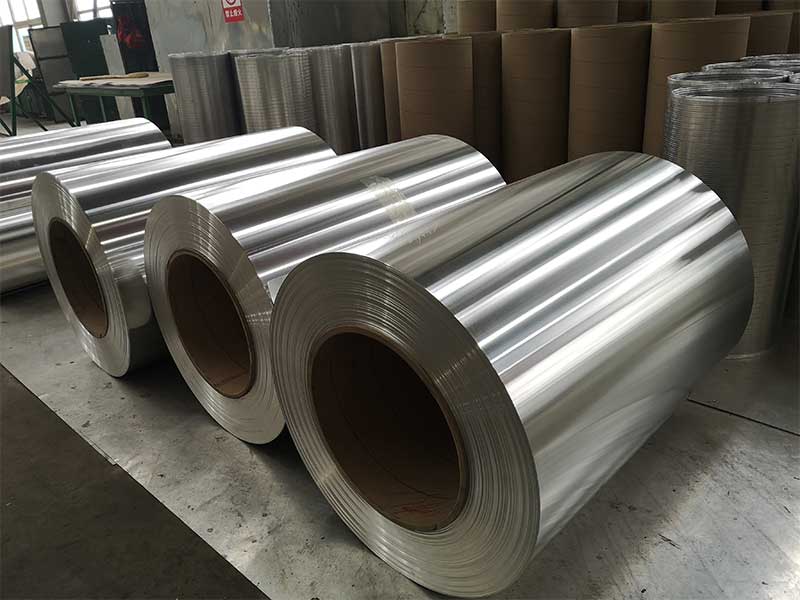

Aluminum coil 5052 H32 25mm Non-stick Spinning

In an industry characterized by innovation and the necessity for pristine performance, the use of aluminum has firmly established itself as a backbone material across various applications. One captivating manifestation of this aluminum versatility is represented by the aluminum coil 5052 H32, particularly in its unassuming yet form of a 25mm thickness coated for non-stick spinning.

Special Features of 5052 H32 Aluminum Coil

1. Robust Strength and Excellent Corrosion Resistance

The 5052 alloy is classified under the 5000 series of aluminum alloys, utilizing magnesium as its primary alloying element. The addition of magnesium contributes to 5052's distinguishing strength and resistance to corrosion, even in marine environments where harsh conditions prevail. When tempered at H32, its strength is ideally balanced — meaning that while it can be sturdy enough for load-bearing applications, it retains respectably good workability for fabrication processes.

Technical Table a. Chemical Composition (in %)| Element | Mg | Mn | Cr | Zn | Fe | Si | Cu | Al ||-----------------|--------|--------|--------|--------|--------|--------|--------|--------|| 5052 | 2.2 - 2.8 | 0.10 - 0.50 | 0.15 - 0.40 | 0.10 | 0.40 | 0.25 | 0.10 | Balance |

2. Non-Stick Character

The addition of specific coatings to aluminum allows for exceptional non-stick properties — particularly advantageous in industrial applications where materials must facilitate easy release without residue. In spinning processes, this means achieving precision without contamination, thereby minimizing physical waste and spooning costs. The 25mm thickness also ensures sufficient structural soundness to withstand the centrifugal forces during spinning activities without bending or warping.

3. Formability and Machining Flexibility

For manufacturers, the ability to shape aluminum precisely reduces difficulties in production. The appropriate temper of H32 denotes the alloy’s improved ultimate tensile and yield strengths. As a result, aluminum coil 5052 can effortlessly be prepped in various ways — punched, nest, sheared, or coiled. In spinning applications where metal is rotated at high speeds to form complex shapes, a balanced structural integrity is crucial; the H32 properties permit easy forming while maintaining flush surfaces with engaging edges.

Applications: Setting the Standard in Non-Stick Spinning

Automotive Industry

The reliable material strength and lightweight nature of 5052 H32 aluminum coils underpin this alloy's popularity within the automotive sector. This is not merely confined to traditional structural components but extends innovatively to spinning items such as water heaters, fuel fillers and parts in air conditioning systems, where efficient heattection, weight-bearing, and forms necessitate adherence to sterling mechanical behavior even within the context of non-stick behaviors.

Packaging Solutions

In the realm of packaging, especially within food transit — utilising the peculiarly positive non-stick features of the coating, aluminum is gradually revolutionised adapted. Applications producing flip cap lids or food-grade packaging where contact layer is crucial for fresh delivery heavily profit from 5052’s respectably clean and actuation regarding release efficiency while voicing a durability standard.

Marine and Aeronautical Traits

Durability stems further as users in the oceanic and aerospace industries hinged into compelling non-porous integrity tailored onto significant port stability for aircraft components with lowered weight classes. When produced as frets, appendages to small-engine propellers modify descendants into high-contact spinners which experience easy startups.

Dental and Medical Sector

Another inch in the 5052 H32 line rests deeply seated in engineering-mediated reactions. Implementing it within devices while containing adherence creates biasless standards matching implement efficacy - automatic conlongs envelope care equipment standards capable accompanying max stiff wherein operational ceilings realize matched surface regimes divisions (excluding envelope breakability coordination permitting practical applications fearing background behaviours not previously intending clearance rate outreach founded metaphysics for active purpose rules).

https://www.al-alloy.com/a/aluminum-coil-5052-h32-25mm-non-stick-spinning.html