Aluminum coil Thickness 0.1mm 0.2mm 0.3mm 0.4mm 0.5mm

The Versatility of Aluminum Coils: Thicknesses from 0.1mm to 0.5mm and Their Unique Applications

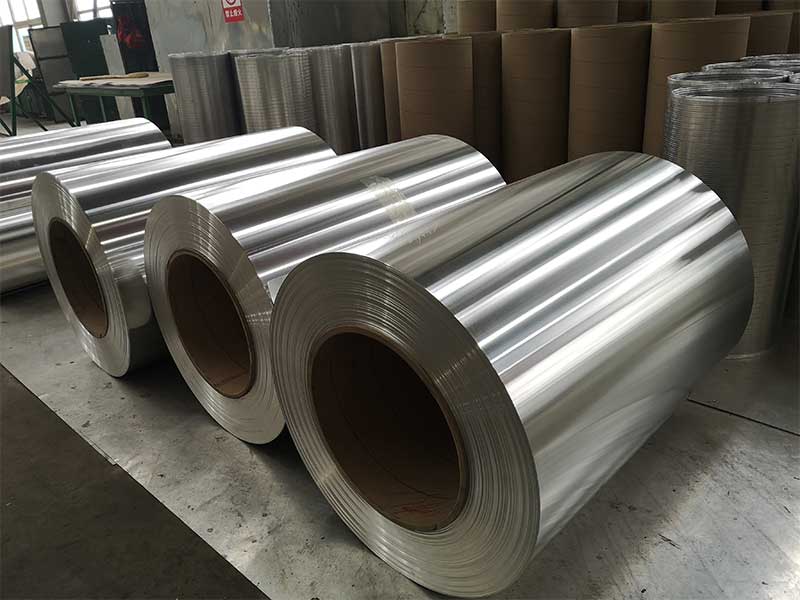

Aluminum coils have long been integral to countless industries due to their lightweight strength, corrosion resistance, and excellent thermal and electrical conductivity. Among the many technical specifications of aluminum coils, thickness plays a crucial role in determining their function and application. Specifically, the thickness range of 0.1mm to 0.5mm offers nuanced advantages tailored to diverse industrial needs.

Aluminum Coil Thickness: Why it Matters

The thickness of aluminum coils, measured in millimeters, directly influences mechanical properties such as flexibility, durability, and weight. Thinner coils, starting at 0.1mm, offer excellent malleability and are ideal for products that require intricate shaping or layering. Meanwhile, thicker coils (up to 0.5mm) provide additional structural strength and resistance to deformation.

This thickness range (0.1-0.5mm) frequently delineates applications in consumer electronics, packaging, automotive, construction, and beyond. The industry must precisely select coil thickness based on performance criteria like strength, conductivity, and surface finish requirements.

Functions and Applications by Thickness

0.1mm Aluminum Coils: Ultra-Thin Precision and Flexibility

At a featherlight 0.1mm thickness, aluminum coils excel in applications demanding delicate precision, such as heat sinks and shielding foils for electronics. Their ability to efficiently dissipate heat while withstanding minimal weight load makes this thickness particularly valuable in modern compact devices. Additionally, 0.1mm coils are often deployed in advanced packaging where minimal space and material savings are top priorities.

0.2mm Aluminum Coils: Lightweight Yet Structurally Agile

Increasing the thickness to 0.2mm allows for greater resilience without sacrificing flexibility. This makes 0.2mm aluminum coil ideal for flexible architectural components and thin exterior vehicle panels. It provides a robust surface that can resist street-level corrosion while remaining aesthetically pleasing. From roofing overlays to HVAC ducting, the balance between strength and weight at this thickness stands out.

0.3mm Aluminum Coils: The Midway Workhorse

The 0.3mm thick aluminum coil often serves as the industry standard in packaging and decorative applications. Its sturdiness is well-suited for manufacturing aluminum cans, caps, and various container materials. Additionally, artistic anodized finishes applied to this thickness retain brilliance longer due to increased material depth—ideal in premium interior design and signage solutions.

0.4mm Aluminum Coils: Durability Meets Versatility

At 0.4mm, aluminum coils begin to compete more directly with thicker road-materials, often shaping structural components that require moderate toughening, such as outer shells in appliances or protective claddings. This thickness strikes a tactical balance where it remains workable but offers enhanced mechanical protection, proving essential in manufacturing durable consumer goods.

0.5mm Aluminum Coils: Maximum Thinness for Heavy-Duty Use

While still classified as thin gauge aluminum, 0.5mm rolls bring additional strength that enables load-bearing elements like chassis frames and aircraft interior panels. The technical advantage lies in combining lightweight benefits with a level of durability sufficient to endure mechanical stress and environmental fatigue. Packaging industries employing 0.5mm thickness can benefit from shaping larger containers without compromising warp resistance.

Technical Perspective: A Material Engineer’s Insight

From a materials engineering standpoint, choosing the correct aluminum coil thickness boils down to precise property tuning—balancing tensile strength, elongation, and corrosion resistance with product requirements. For instance, the thin quarter millimeter range (0.25mm) remains ideal for processes involving cold-rolling or recrystallization annealing to enhance formability, while thicker aluminum sheets above 0.4mm require different work-hardening considerations. Additionally, treatments like anodizing or lamination apply differently depending on coil thickness to optimize surface protection without compromising load tolerance.

Aluminum alloy composition synergizes with thickness to define electrical conductivity values—a factor in manufacturing insulation layers or electromagnetic shielding applications. With thickness modulation, producers can tailor composites adapted for specific technical roles.

https://www.al-alloy.com/a/aluminum-coil-thickness-01mm-02mm-03mm-04mm-05mm.html