Aluminum foil for blister pack for pharmaceutical

Aluminum foil plays a critical role in the pharmaceutical industry, especially as a packaging material for blister packs. Its unique characteristics ensure the preservation of medicinal products while maintaining safety, hygiene, and compliance with regulatory standards.

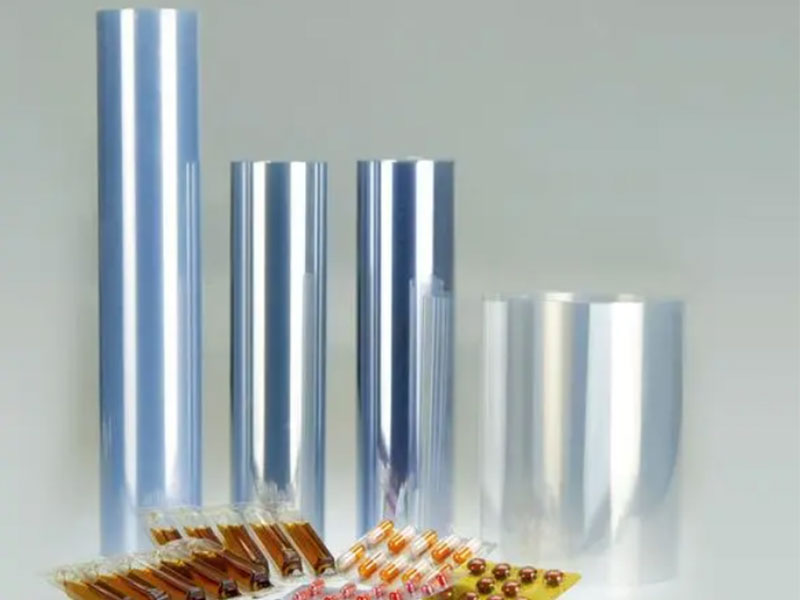

In pharmaceutical packaging, aluminum foil for blister packs serves as an environmental barrier, protecting drug products from moisture, oxygen, light, and contamination. Its versatility and reliability make it an optimal choice for preserving the stability and efficacy of medicines such as tablets, capsules, and soft gels.

Why Use Aluminum Foil for Blister Packs?

- Excellent barrier to moisture, air, and light

- High corrosion resistance prevents interaction with medicines

- Ideal thickness and mechanical strength allow for efficient packaging

- Compatible with various coatings and laminates for additional protection

- Cost-effective and recyclable, supporting sustainability goals

Features

| Feature | Description |

|---|---|

| Barrier Properties | Impermeable to oxygen, moisture, and UV light |

| Heat Resistance | Suitable for thermoforming and thermo sealing processes |

| Mechanical Strength | Balances malleability with tensile and puncture resistance to withstand packaging operations |

| Surface Coating Compatibility | Can be laminated with polymer films or coated with inks for printing and brand labeling |

| Pharmaceutical Compliance | Meets FDA, EU Pharmacopeia, and other regulatory standards |

| Customization | Available in varying gauges, widths, and finishes depending on blister pack machinery and drug specifics |

Chemical Composition

Typically, aluminum foil for pharmaceutical blister packs is made of high purity aluminum to guarantee exceptional barrier performance.

| Element | Typical Composition (%) | Purpose/Benefit |

|---|---|---|

| Aluminum (Al) | 99.3 – 99.8 | Core metal ensuring foil purity and barrier quality |

| Iron (Fe) | 0.4 – 0.7 | Controls foil strength and formability |

| Silicon (Si) | 0.05 – 0.20 | Enhances corrosion resistance |

| Copper (Cu) | ≤ 0.05 | Generally minimized to maintain chemical inertness |

| Others | ≤ 0.1 | Trace metals minimized in high-purity grades |

Mechanical & Physical Properties

| Parameter | Typical Value | Unit | Description |

|---|---|---|---|

| Thickness | 15 – 60 | Micrometers (µm) | Determines barrier characteristics & flexibility |

| Tensile Strength | 90 – 120 | MPa | Resistance to tearing and deformation during packing |

| Elongation at break | 5 – 15 | % | Indicative of foil flexibility and ductility |

| Puncture Resistance | 18 – 25 | MPa | Critical for withstanding packing pressures |

| Density | 2.70 | g/cm³ | Standard for pure aluminum |

| Melting Point | 660 | °C | Allows for heat sealing during packaging |

Technical Specifications

| Attribute | Value Range | Notes |

|---|---|---|

| Gauge Thickness | 15µm to 60µm | Customized to match blister pack design and sealing process |

| Width | 100mm to 600mm | Adaptable to blister packing machines |

| Coating/Covering Type | PVDC, Acrylic, or Electrolytic | For enhanced moisture and oxygen resistance |

| Lamination Capability | Polymer laminates (PVC/PVDC) or Paper | Forms multilayer structures for blister packaging |

| Surface Finish | Bright / Matt | Depending on printing & branding requirements |

| Roll Length | According to customer requirement | Typical range: 1000 – 6000 m |

Performance & Benefits

- Moisture Barrier: Prevents degradation of moisture-sensitive drugs by blocking humidity ingress.

- Light Barrier: Protects photosensitive pharmaceuticals, maintaining efficacy over a product's shelf life.

- Oxygen Barrier: Blocks atmospheric oxygen that may cause oxidation or reduce shelf stability.

- Puncture Resistance: High mechanical strength prevents accidental damage and preserves seal integrity.

- Thermal Compatibility: Suitable for thermoforming with plastics like PVC and PET, facilitating blister pack manufacture.

- Regulatory Compliance: Manufactured and processed to meet stringently the FDA Code of Federal Regulations, USP, EP standards.

Applications

| Pharmaceutical Product Type | Application Detail |

|---|---|

| Tablets and Capsules | Primary protection layer in blister packs, preventing contamination and moisture |

| Soft Gels | Barrier to maintain shape integrity and prevent oxygen exposure affecting pliability |

| Over-the-Counter Medicines | Used for engaging branding with printed aluminum, assuring theft protection |

| Vaccines and Temperature Sensitive Products | Often laminated foils for additional protection against light and environment |

The use of high-quality aluminum foil customized for pharmaceutical blister packaging provides exceptional protective performance, durability, and compliance assurance. By choosing aluminum foil with optimal thickness, mechanical properties, and surface treatments, pharmaceutic manufacturers can significantly improve their packaging efficacy, safeguard product quality, and comply with global regulation standards.

Embracing aluminum foil in blister packs ensures extended product shelf life, excellent consumer safety, and alignment with sustainable packaging practices.

For detailed technical consultation or custom requirements, please contact our technical support team or request our product datasheet.

https://www.al-alloy.com/a/aluminum-foil-for-blister-pack-for-pharmaceutical.html