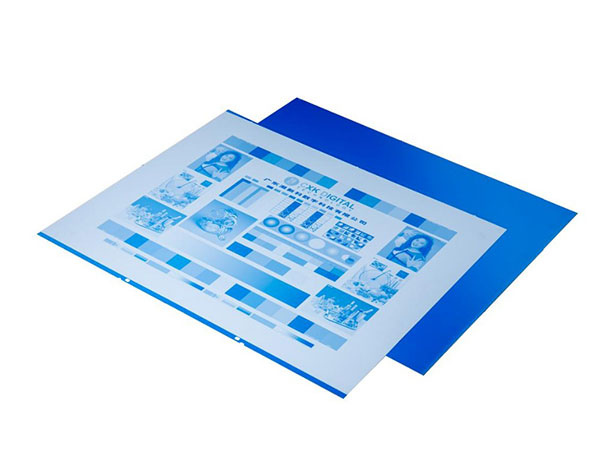

UV CTP CTCP printing plates use on offset printing machine

UV CTP (Computer-to-Plate) and CTCP (Computer-to-Conventional-Plate) printing plates are the workhorses of modern offset printing, turning digital layout files into stable, high-resolution printing surfaces with speed and repeatability. Built on carefully grained and anodized aluminum, these plates are engineered to carry sharp dots, resist press chemistry, and deliver consistent ink-water balance across long runs. For commercial printers, packaging converters, and newspaper plants, UV CTP/CTCP plates offer a practical blend of image fidelity, press durability, and process tolerance-especially where UV plate setters or CTCP exposure systems are already part of the workflow.

What Makes UV CTP and CTCP Plates Different?

Both plate types use an aluminum base with a photosensitive coating that forms the image after exposure and processing.

- UV CTP plates are optimized for UV laser imaging systems. They are designed for precise dot reproduction, stable tone transfer, and fast plate-making cycles in busy prepress rooms.

- CTCP plates are designed to work with more "conventional" exposure/processing expectations, providing a cost-effective bridge between traditional PS plates and fully thermal workflows.

In practice, both are commonly used on sheet-fed and web offset presses, with reliable performance across commercial printing, books, and packaging applications-when paired with the right developer, fountain solution, and press settings.

Product Features That Matter on Press

High-fidelity imaging and dot stability

A strong plate must hold highlights without dropping dots and keep midtones smooth without graininess. UV CTP/CTCP coatings are formulated to form clean edges after development, supporting fine screens and sharp text.

Consistent ink-water balance

Offset success depends on stable hydrophilic non-image areas and oleophilic image areas. The anodized aluminum layer and post-treatment help maintain water receptivity and reduce toning, even under longer runs.

Durable aluminum base for long runs

The aluminum substrate is electrochemically grained and anodized to create a micro-porous surface that anchors the coating and improves abrasion resistance, helping the plate withstand blanket pressure, dampening rollers, and chemical exposure.

Fast make-ready and predictable reproduction

When plates develop cleanly and consistently, press operators spend less time chasing color and balance. Well-controlled coating weight, anodic film quality, and surface roughness translate into faster stabilization during make-ready.

Aluminum Substrate: Why It Dominates Plate Performance

The plate base is typically an aluminum alloy chosen for formability, consistent graining response, and corrosion resistance. While exact grades vary by manufacturer, the chemistry is controlled to reduce defects and deliver stable electrochemical behavior during graining and anodizing.

Typical Aluminum Base Chemical Composition (Reference Range)

| Element | Typical Range (wt%) | Why It Matters for Plates |

|---|---|---|

| Al | Balance | Provides lightweight, stiffness, and corrosion resistance foundation |

| Fe | 0.20–0.60 | Controlled to avoid inclusions; affects surface uniformity |

| Si | 0.10–0.40 | Impacts grain structure and anodizing response |

| Mn | 0.00–0.30 | Helps control strength and microstructure stability |

| Mg | 0.00–0.30 | Can influence hardness and chemical reactivity |

| Cu | 0.00–0.10 | Kept low to improve corrosion resistance |

| Zn | 0.00–0.20 | Low level supports stability; excess may affect corrosion |

| Ti/Cr (trace) | 0.00–0.05 | Grain refinement and process stability in rolling |

Note: Actual composition depends on the specific plate base alloy and supplier melt control. Plate base quality is validated more by surface and electrochemical performance than by chemistry alone.

Technical Specifications (Typical Product Window)

UV CTP/CTCP printing plates are usually offered in multiple thicknesses and sensitivities to match press type and imaging equipment. The values below represent commonly supplied industrial ranges.

| Parameter | Typical Range / Option | Notes for Offset Printing Machine Use |

|---|---|---|

| Plate type | UV CTP / CTCP | Selected based on imaging system and workflow |

| Plate base | Grained & anodized aluminum | Ensures water receptivity and coating adhesion |

| Thickness | 0.15 mm / 0.20 mm / 0.25 mm / 0.30 mm / 0.40 mm | Thicker plates improve rigidity on large formats |

| Standard widths | 300–1400 mm (custom possible) | Matched to press format and plate bender requirements |

| Length | 400–2000+ mm (custom possible) | Depends on press cylinder circumference |

| Surface roughness (Ra) | 0.35–0.65 μm (typical) | Supports water retention and stable ink-water balance |

| Anodic layer | 1.0–3.0 g/m² (typical) | Higher anodizing improves wear resistance |

| Coating color | Commonly green/blue (varies) | Aids inspection and handling |

| Imaging energy / sensitivity | System-dependent | Determined by plate setter power and speed |

| Processing | Compatible with standard developers | Developer choice impacts clean-out and dot gain |

| Run length | Commonly 50,000–200,000+ impressions* | Depends on press, paper, chemistry, and baking option |

*Run length varies widely. Coating type, fountain solution conductivity/pH, blanket condition, and press pressure are major contributors.

Performance on Offset Printing Machines

Stable printing latitude

On press, UV CTP/CTCP plates are valued for tolerance to small variations in dampening and ink keys. A well-made plate maintains non-image cleanliness, helping reduce background toning and minimizing the need for aggressive fountain solution settings.

Clean highlights and solid ink density

The coating's image area must accept ink rapidly while keeping edges crisp. This leads to better microtext reproduction, smoother gradients, and stronger solids-especially important for packaging and high-coverage commercial work.

Reduced plate-related downtime

Uniform graining and consistent anodizing reduce risk of scumming, poor development, or coating pick-off. That means fewer remakes, fewer stoppages, and more consistent color from plate to plate.

Compatibility with common press chemistry

UV CTP/CTCP plates are designed to work with standard dampening solutions and plate cleaners typically used in offset shops. Matching chemistry to coating recommendations improves press stability and extends plate life.

Applications: Where UV CTP and CTCP Plates Excel

Commercial printing

Brochures, catalogs, posters, corporate stationery, and general jobbing work benefit from quick plate turnaround and reliable tone reproduction. For mixed jobs and frequent changeovers, consistent plate behavior reduces makeready waste.

Packaging and labeling

Folding cartons, inserts, tags, and certain label segments demand sharp solids, clean reverses, and predictable trapping. Plates with good abrasion resistance help maintain quality through higher ink coverage and longer runs.

Publishing and books

Text-heavy jobs need strong line definition and stable midtones. Plate consistency supports uniformity across signatures and reduces risk of visible variation between forms.

Newspaper and short-deadline production

For operations that prioritize speed and cost efficiency, UV CTP/CTCP plates can provide a practical balance of imaging speed and acceptable run length, especially when workflows are already standardized around UV exposure systems.

Buying Considerations for Customers

| Customer Need | What to Choose / Verify | Practical Benefit |

|---|---|---|

| Maximum on-press durability | Higher anodizing, robust coating, suitable thickness | Longer run length and fewer plate changes |

| High-resolution fine screen work | Stable imaging response and clean development | Better dot fidelity and smoother gradients |

| Fast turnaround | Plate sensitivity matched to imager | Faster plate output with consistent quality |

| Press stability | Verified roughness/anodic consistency | Lower toning risk and easier ink-water balance |

| Lower cost per plate | CTCP option with proven processing latitude | Efficient production without over-specification |

UV CTP and CTCP printing plates are engineered aluminum-based materials designed to translate digital files into reliable offset performance. Their strongest value comes from the combination of a controlled aluminum substrate, uniform graining/anodizing, and a coating system tuned for clean development and stable press behavior. Whether used for commercial jobs, packaging work, books, or fast-cycle production, these plates help printers achieve crisp detail, consistent color, and predictable run performance-while keeping plate-making efficient and press time productive.

https://www.al-alloy.com/a/uv-ctp-ctcp-printing-plates-use-on-offset-printing-machine.html