Mirror aluminum plate 1060

Mirror aluminum plate 1060 is a widely used reflective aluminum sheet known for its excellent surface quality, high corrosion resistance, and outstanding malleability. With its brilliant mirror-like finish, this aluminum alloy plate is popular across industries that require both functionality and aesthetic appeal.

Belonging to the 1000 series of aluminum alloys, 1060 aluminum is almost pure aluminum (minimum 99.6%), recognized for excellent thermal and electrical conductivity, good corrosion resistance, and high ductility. The mirror finish aluminum plate enhances these inherent qualities with a polished surface that reflects up to 80% of visible light, offering both decorative and practical value.

Functions and Benefits

The mirror aluminum plate 1060 offers multiple benefits that make it a critical material in various sectors:

Reflectivity and Aesthetics

Its ultra-smooth and highly polished surface reflects light efficiently, providing superior brightness and decorative appeal for architectural elements, signage, or product components.Corrosion Resistance

The natural oxide layer on alloy 1060 imparts excellent resistance to atmospheric conditions and many chemicals, which extends product longevity.Lightweight and Durable

Aluminum 1060 maintains an excellent strength-to-weight ratio, allowing flexible formability while maintaining reasonable mechanical strength after tempering.Thermal and Electrical Conductivity

Due to its purity, the alloy efficiently conducts heat and electricity, making it suitable for heat exchangers and electrical equipment where reflective properties support performance.Ease of Fabrication

The alloy melts and machines easily, and the mirror finishing process ensures the surfaces are resistant to tarnishing or corrosion without affecting alloy integrity.

Typical Applications

Because of these properties, mirror aluminum plate 1060 is widely deployed in:

- Decorative cladding and architectural panels

- Elevator interiors and decorative surfaces

- Reflectors for lighting and solar energy collectors

- Kitchen appliances and cookware surfaces

- Electrical enclosures and heat sinks

- Art installations and showroom displays

- Advertising boards and signage due to high visibility and appeal

Technical Parameters and Standards

Implementation Standards

| Standard | Description |

|---|---|

| ASTM B209 | Specification for aluminum and aluminum-alloy sheet and plate |

| GB/T 3880 | Aluminum and aluminum alloy chemical composition standards (China National Standard) |

| JIS H4100 | Japanese Industrial Standard for aluminum and aluminum alloy |

| EN 485-2 | European Standard for aluminum sheets and plates |

Alloy and Tempering Conditions

| Alloy Number | Temper | Properties | Description |

|---|---|---|---|

| 1060 | H14 | Cold worked | Harder and less ductile than O temper |

| 1060 | H18 | Full hard | Maximum strength for cold-working |

| 1060 | O | Annealed (soft) | Highest ductility and formability |

H14 and H18 tempers offer higher strength for structural use, while O temper is preferred for applications requiring deep drawing and extensive forming.

Chemical Composition (% by Weight)

| Element | Minimum | Maximum | Typical Value |

|---|---|---|---|

| Aluminum (Al) | 99.6 | – | 99.6–99.8 |

| Iron (Fe) | – | 0.35 | 0.2 |

| Silicon (Si) | – | 0.25 | 0.1 |

| Copper (Cu) | – | 0.05 | 0.02 |

| Manganese (Mn) | – | 0.03 | 0.01 |

| Magnesium (Mg) | – | 0.03 | 0.02 |

| Zinc (Zn) | – | 0.05 | 0.01 |

| Titanium (Ti) | – | 0.03 | 0.005 |

| Others | – | 0.05 | Trace |

Mechanical Properties

| Property | Temper | Typical Values | Units |

|---|---|---|---|

| Tensile Strength | O | 55–70 | MPa |

| Tensile Strength | H14 | 85–115 | MPa |

| Yield Strength | O | 30–40 | MPa |

| Yield Strength | H14 | 40–75 | MPa |

| Elongation (%) | O | ≥ 25 | % |

| Elongation (%) | H14 | 5–10 | % |

| Hardness (Brinell) | O | 15–25 | HB |

| Hardness (Brinell) | H14 | 30–45 | HB |

| Density | – | 2.7 | g/cm³ |

Thermal and Electrical Conductivity

| Parameter | Value | Unit |

|---|---|---|

| Thermal Conductivity | ~220 (1060-O) | W/m·K |

| Electrical Conductivity | 59–62 (IACS %) | % IACS |

| Melting Point | 640–650 | °C |

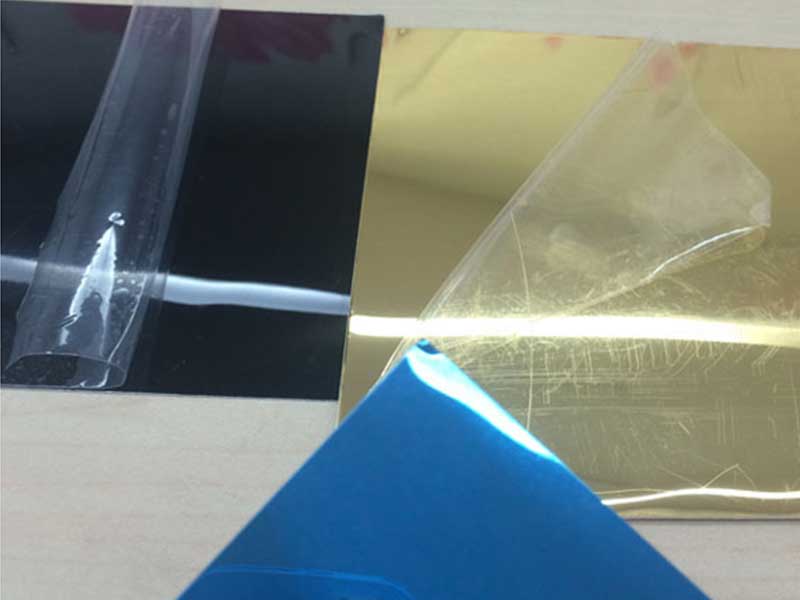

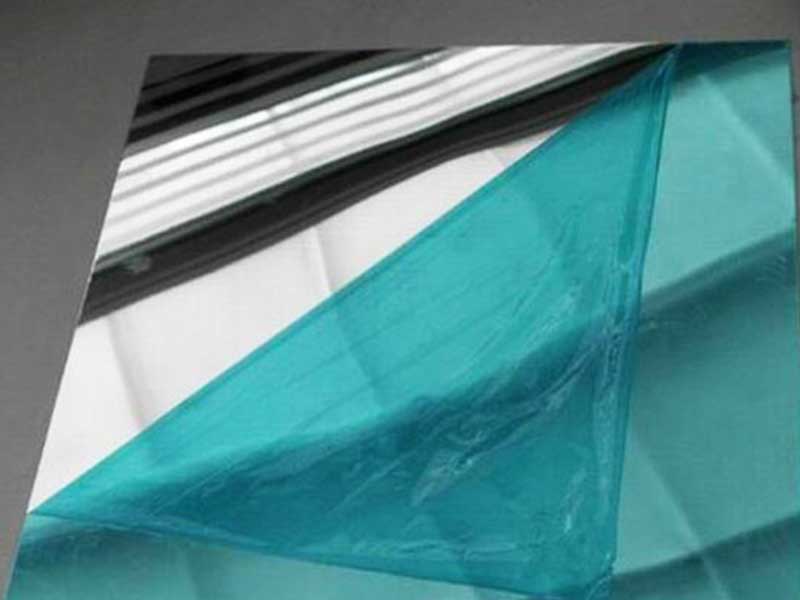

Surface Finish Features

The mirror aluminum plate 1060 achieves its gleaming appearance via a multi-step polishing and buffing process that imparts:

- High resistance to oxidation and rust

- Low surface roughness (Ra typically < 0.2 μm)

- Excellent reflectivity (~80%) suitable for optical and aesthetic applications