0.0055mm-0.03mm Laminated Aluminium foil

0.0055mm–0.03mm Laminated Aluminium Foil: The "Invisible Interface" That Makes Packaging, Insulation, and Protection Work

When people think about aluminium foil, they often picture a shiny sheet that wraps food. In industrial reality, ultra-thin laminated aluminium foil in the 0.0055mm–0.03mm range is less a "sheet" and more an engineered interface. It is the silent layer that blocks oxygen, seals in aroma, reflects heat, stabilizes structures, and protects sensitive products from moisture, light, and contamination-while being thin enough to disappear into a laminate.

This thickness range is where aluminium becomes a high-performance functional film. At 5.5–30 microns, foil is light, flexible, and responsive to lamination design choices such as adhesive type, polymer pairing, coating selection, and temper condition. The result is not just "foil + plastic," but a tuned barrier system that behaves differently depending on whether it is used for pharmaceutical blister packs, food pouches, insulation facings, or battery-related packaging.

What Laminated Foil Really Does: Function First, Thickness Second

In laminated structures, aluminium foil typically plays four core roles, but its true value lies in how reliably it performs them in extremely thin gauges.

Barrier performance is the headline feature. Aluminium is essentially impermeable to gases and light when intact, which makes it ideal for protecting oxygen-sensitive foods, aroma-rich products like coffee, and light-sensitive pharmaceuticals. At ultra-thin gauges, the laminate design must also prevent pinholes and flex cracking, so foil quality and temper matter as much as thickness.

Thermal reflectivity and insulation enhancement are often underestimated. Laminated foil reflects radiant heat, and when combined with air gaps, foams, or kraft paper, it becomes a highly effective facing for insulation, duct wrap, roofing underlays, and thermal packaging.

Seal integrity and process compatibility come from pairing the foil with heat-sealable layers such as PE, PP, PET, or specialized sealant resins. Foil itself is not always the sealing layer; it is the barrier and structural backbone that supports consistent sealing behavior through the laminate.

Mechanical stability and tactile feel may be the most "invisible" function. Foil improves stiffness, dead-fold behavior, puncture resistance, and premium hand-feel in packaging-especially noticeable in sachets, stick packs, lids, and wraps.

Parameters at a Glance: Practical Ranges for 0.0055mm–0.03mm Foil

Because lamination performance depends on end-use, buyers usually specify foil by thickness, alloy/temper, surface condition, and pinhole limits rather than only by weight.

Typical thickness range: 0.0055mm–0.03mm

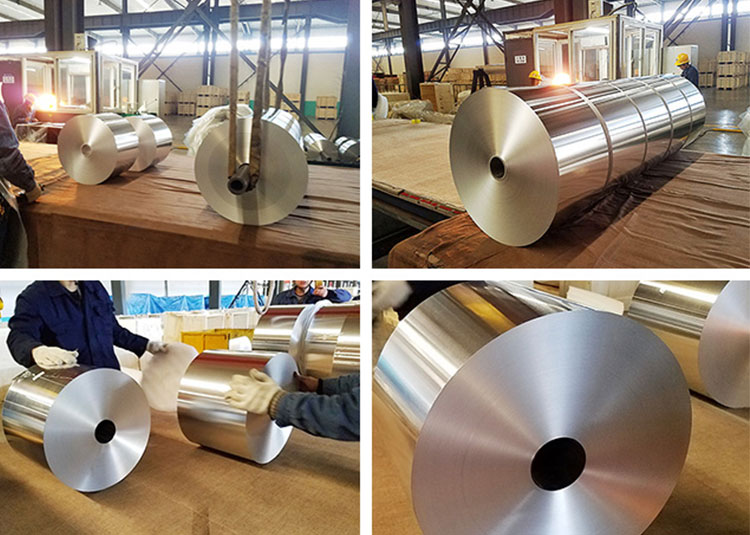

Common width range: custom slit widths; large-jumbo rolls available for converters

Inner core: 3 inch or 6 inch (customizable)

Surface options: one-side bright / two-side bright, matte/bright combinations, primer-coated, lacquered, or treated for adhesive bonding

quality indicators: pinhole count, surface cleanliness, wetting tension (if coated/treated), thickness tolerance, roll flatness, and splice control

Ultra-thin foil tends to be selected when flexibility and laminate efficiency are prioritized. As thickness moves closer to 0.03mm, puncture resistance and forming performance improve, which is useful for certain lids, pharmaceutical and medical packaging, and robust insulation facings.

Alloy and Temper: The Design Lever Behind Formability and Strength

A distinctive way to choose laminated foil is to treat alloy and temper like "behavior settings" rather than chemical labels. The same thickness can act soft and conformable or firm and shape-stable depending on temper.

Common alloys for laminated aluminium foil

8011 is widely used for packaging due to balanced strength, good barrier performance, and stable processing behavior.

1235 is known for high aluminium purity and excellent ductility, often used where softness and formability matter.

8079 is commonly chosen for high-end packaging and pharmaceutical uses where better strength and pinhole resistance are expected at low thickness.

Typical temper conditions

O (soft annealed) is preferred for deep forming, better dead-fold, and smoother lamination conformability.

H18 (full hard) offers higher strength and stiffness, useful where wrinkle resistance and dimensional stability matter.

H19/H22/H24 may be used depending on converter preference; many laminated foil structures favor soft temper for reliability in converting.

For many flexible packaging laminates, 8011-O or 1235-O are common workhorses. For applications that are sensitive to pinholes at very thin gauges, 8079 is frequently specified.

Implementation Standards and Common Compliance References

Laminated aluminium foil is usually produced and inspected under widely recognized aluminium and packaging standards, then verified against converter-specific requirements.

Typical referenced standards include:

ASTM B479 / ASTM B373 for aluminium foil general requirements and testing practices

EN 546 series for aluminium and aluminium alloys foil specifications (often used in EU-linked supply chains)

GB/T standards commonly referenced in China-based production and inspection workflows for foil and packaging materials

ISO 9001 quality system alignment is commonly expected for stable roll-to-roll manufacturing

For food and pharmaceutical packaging, additional compliance may be required depending on destination market, such as FDA or EU food-contact frameworks, and migration testing on the final laminate structure rather than the foil alone.

Chemical Properties: Typical Composition Table (Reference)

The foil's chemical composition influences corrosion behavior, strength potential, and processing stability. Actual composition should be confirmed by mill test certificate for each batch.

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|

| 1235 | ≤0.65 | ≤0.65 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.06 | ≥99.35 |

| 8011 | 0.50–0.90 | 0.60–1.00 | ≤0.10 | ≤0.20 | ≤0.05 | ≤0.10 | ≤0.08 | Remainder |

| 8079 | ≤0.30 | 1.00–1.30 | ≤0.10 | ≤0.10 | ≤0.05 | ≤0.10 | ≤0.08 | Remainder |

These are commonly cited ranges in industry practice; individual specifications may vary slightly by standard and manufacturer.

Applications: Where 0.0055mm–0.03mm Laminated Foil Excels

Food packaging laminates use foil as the "aroma vault." Coffee, tea, chocolate, spices, dairy-based powders, and retort-ready foods depend on aluminium's light and oxygen barrier. In multi-layer pouches, foil typically sits between PET (printability and strength) and PE (sealability), forming a structure that protects product quality throughout distribution.

Pharmaceutical and medical packaging relies on foil for stability and shelf-life. While blister lidding foils may be thicker in some cases, many laminated medical packaging materials use ultra-thin foil layers to block moisture and oxygen while maintaining processability on high-speed lines.

Insulation facings and HVAC applications use laminated foil to reflect radiant heat and act as a vapor barrier. When bonded with kraft paper, scrim, or fiberglass reinforcement, foil becomes a building-envelope component rather than a packaging material-helping improve energy efficiency and moisture control.

Industrial and chemical packaging benefits from foil's chemical resistance and barrier properties when paired with compatible polymers. Laminated foil liners and sachets protect hygroscopic powders and reactive materials by isolating them from ambient humidity.

Battery-associated packaging and protective wraps often leverage laminated foil structures for shielding, barrier protection, and thermal management in certain peripheral components. Exact suitability depends on laminate design, cleanliness level, and application-specific validation.

A Practical Way to Specify: Think in "Conversion Reality"

The most effective procurement approach is to specify laminated aluminium foil based on how it will be converted, not just what it is. Ask whether the laminate will be printed, whether it will be hot-filled or retorted, whether it will be deep-formed, and how much flexing the package will experience in logistics. In ultra-thin gauges, pinhole control, surface cleanliness, and the right temper selection often determine success more than the nominal thickness.

https://www.al-alloy.com/a/00055mm-003mm-laminated-aluminium-foil.html