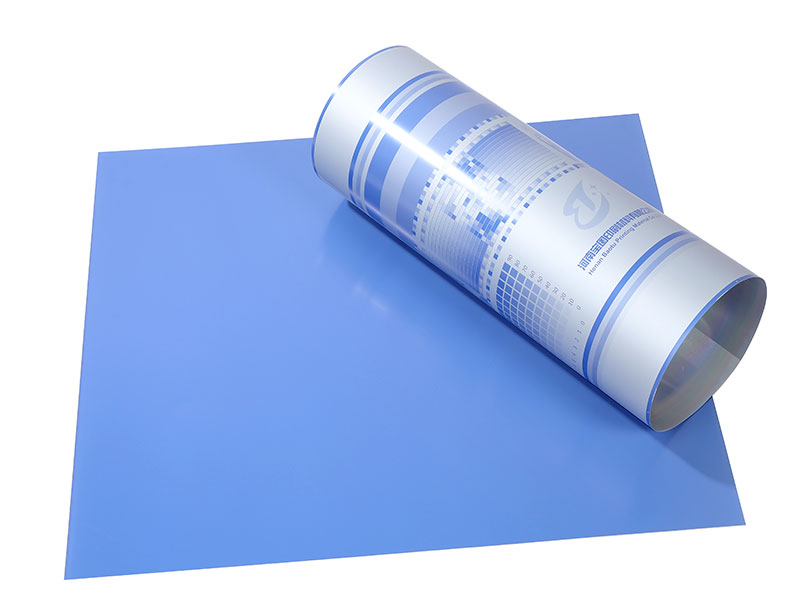

Aluminum Plate CTP Offset Printing Thermal Custom Sizes Daylight Plates

In the world of modern printing technology, the demand for high-quality, durable, and precise printing plates has never been greater. Aluminum CTP (Computer-to-Plate) plates, especially those designed for offset printing with thermal daylight capabilities and customizable sizes, have become indispensable components in professional print production.

Aluminum CTP plates refer to precision-engineered printing plates made from high-grade aluminum alloys, structured specifically for thermal processing. These plates provide a surface onto which digital printing data is directly transferred using laser-based CTP systems, bypassing legacy film-based methods. The “daylight” specification denotes plates that are not highly photosensitive to visible light, allowing safer handling in standard ambient lighting—significantly improving workflow safety and efficiency.

Core Advantages:

- Chemical and manipulation resistance for longer run lengths

- Compatibility with thermal exposure for high-resolution imaging

- Customizable dimensions to suit varied printing presses and job profiles

- Robust aluminum alloy base offering strength and thermal conductivity for precise thermal transfer

- Reduced environmental hazards supported by daylight-safe chemistry reducing ozone generation and processing chemicals

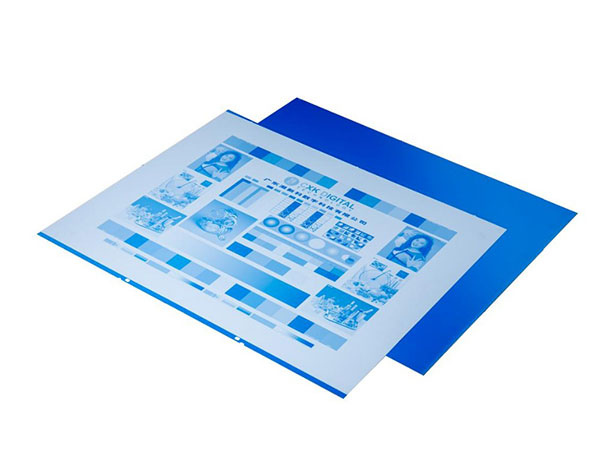

Working Principle

Thermal CTP plates operate by absorbing heat selectively during exposure by a thermal laser of precise wavelength (typically around 830 nm). The heat triggers polymerization or solubilization in the plate’s photosensitive coating, creating the pattern to transfer ink selectively. Daylight-safe coatings involve specific polymers and diazo compounds stabilized against visible light, though sensitive to infrared wavelengths, reducing the need to operate under red safelights or dark rooms.

Detailed Specifications and Parameters

| Parameter | Value/Description |

|---|---|

| Base Material | High-purity aluminum alloy (typically ASTM AA1050 or AA1060) |

| Alloy Temper | O-H14 to O-H24 (cold working degrees for rigidity) |

| Thickness | 0.3 mm to 0.5 mm (customizable according to press type) |

| Surface Roughness | Ra (Average Roughness) 0.1 - 0.2 μm |

| Surface Treatment | Electrochemical anodizing creating pores of ~100 nm for uniform coating adhesion |

| Photosensitive Layer | Thermal polymer monolayer (daylight optimized coating system) |

| Exposure Source | Thermal laser at 830 nm |

| Run Length Capability | Up to 300,000 impressions (run dependent) |

| Plate Chemistry | Oils and alkaline water wash adaptable |

Aluminum Alloy Temper and Quality

The aluminum alloys typically deployed (AA1050/AA1060) feature excellent corrosion resistance and chemiomechanical qualities suited to offset printing:

| Alloy Element Composition (%) | AA1050 | AA1060 |

|---|---|---|

| Aluminum (Al) | Min 99.5 | Min 99.6 |

| Copper (Cu) | 0.05 max | 0.05 max |

| Iron (Fe) | 0.4 max | 0.30 max |

| Silicon (Si) | 0.25 max | 0.25 max |

| Magnesium (Mg) | 0.05 max | 0.05 max |

| Manganese (Mn) | 0.05 max | 0.05 max |

Temper ratings such as O-H14 (15% cold worked hardness) provide improved plate rigidity without compromising flexibility, for stability during press runs.

Implementation Standards in Offset Printing

Established industry standards influence plate manufacturing and usage intents:

Working with custom-sized aluminum CTP plates for daylight offset printing presents unique challenges compared to standard sizes. The biggest hurdle is often the increased setup and processing time. While our automated systems are designed for efficiency, handling non-standard dimensions requires manual adjustments, increasing the risk of human error and potentially impacting plate quality. We've found that careful planning and meticulous attention to detail during the pre-press phase are crucial. This includes precise measurements, rigorous quality checks of the raw aluminum, and adapting our imaging and processing parameters to accommodate the specific size and thickness of the custom plate. Even minor variations can lead to registration issues or inconsistencies in image reproduction, ultimately affecting the final print quality and potentially impacting client deadlines.

Furthermore, optimizing the thermal processing for custom sizes requires a nuanced of heat transfer dynamics. Larger plates require longer processing times and potentially necessitate adjustments to the thermal profile to ensure even exposure and development. We've had instances where uneven heating resulted in variations in plate density, leading to inconsistent ink transfer and poor print quality. To mitigate this, we’ve developed internal SOPs that include detailed thermal profiles for various custom sizes, coupled with rigorous testing and quality control measures at each stage of the process. This proactive approach has significantly minimized defects and improved our ability to deliver high-quality custom-sized aluminum CTP plates consistently.

- ASTM B209 for aluminum alloy sheet specifications guarantees compositional purity and mechanical attributes.

- ISO 12647 enables color management standards that depend on high fidelity CTP converters.

- GRACoL and SWOP standards emphasize cobalt shell layer uniformity toward achieving optimal ink transfer media, ensuring plates meet performance specifications.

- Electrochemical anodizing uniformity must meet thickness around 15 microns to increase the plate base corrosion resistance during washes and jabs in the printing process.

Applications of Aluminum CTP Thermal Daylight Plates Custom Sizes

Commercial Printing

Perfect for forms, brochures, packaging, catalogs, where robustness over long print runs matters. Thermal plates yield sharp halftones and photographic quality text impressions with excellent consistency.

Packaging Industry

Direct thermal imaging supports specialty coated substrates for food packaging, requiring hygienic non-toxic chemistry and abrasion-resistant surfaces.

Newspaper Printing

Newspapers benefit from fast-processing daylight plates minimizing downtime and chemical waste. Aluminium plates withstand large cyclic print quantities catering to newspaper demands.

Specialty and Custom Printing

Daylight-safe properties facilitate in-house plate handling with reduced safety precautions. Custom sizes ensure physical dimensions to fit non-standard presses — ranging from sheet-fed presses to web/frame lithographics design.