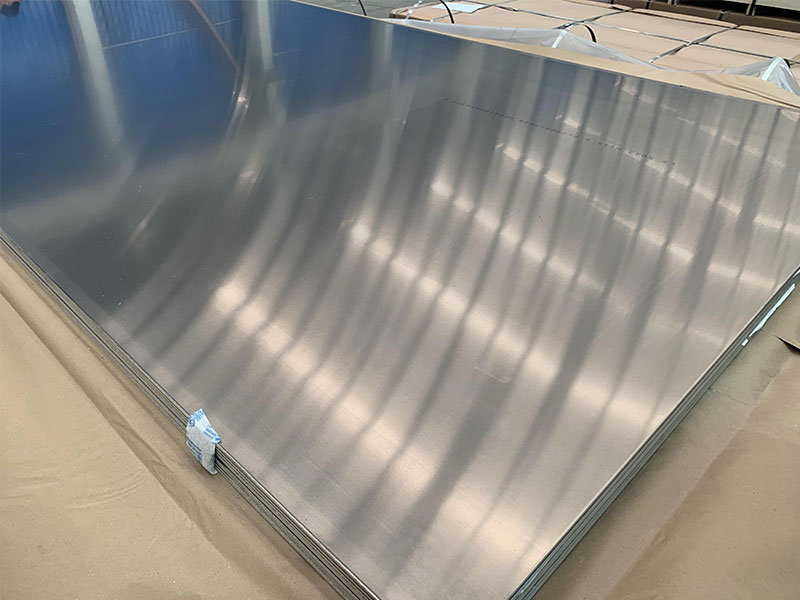

Marine aluminium plate 5052

When navigating the complex world of marine construction and vessel manufacturing, the choice of materials is as critical as the engineering behind them. One such material that stands at the confluence of strength, corrosion resistance, and lightweight efficiency is the marine aluminum plate 5052. Often overshadowed by more commonly discussed metals, this alloy’s unique characteristics and technical specifications make it an indispensable asset in the maritime industry.

Unveiling the Functionality of Marine Aluminum Plate 5052

Marine aluminum plate 5052 is an aluminum-magnesium alloy that has carved its niche for superior performance in oceans' harshest environments. Its primary function revolves around providing durable, corrosion-resistant panels and components that ensure structural integrity without the burden of excessive weight. Unlike typical steel plates, 5052 offers exceptional resistance to seawater corrosion, making it the go-to material for marine decks, hulls, and superstructures.

This resilience is largely thanks to its magnesium content, usually around 2.2% to 2.8%, which enhances its strength and reinforces the protective oxide passive layer that's crucial for repelling saltwater chemistry attacks. The lightweight property of 5052 aluminum also optimizes fuel efficiency in marine vessels, contributing to environmentally friendly maritime solutions.

marine aluminum plate 5052 requires an appreciation of more than just the surface exercise of durability.

- Density: Approximately 2.68 g/cm³ – about one-third the density of steel, lending significant weight savings in construction.

- Tensile Strength: Ranges typically from 220 to 330 MPa depending on the temper, granting adequate strength for structural elements.

- Yield Strength: Varies typically between 140 and 245 MPa, ensuring dependable elasticity limits under stress.

- Elongation at Break: Around 10-20%, indicating good ductility conducive to forming and welding.

- Hardness: Measured between 60 and 95 HRB depending on tempering.

These parameters vary based on the temper condition – critical for manufacturers targeting a balance of workability and mechanical performance.

Alloy Temper and Implementation Standards – The Backbone of Reliability

The versatility of 5052 lies in its multiple temper conditions, each modifying mechanical properties subtly to fit precise applications:

| Temper Code | Description | Typical Use Cases |

|---|---|---|

| H32 | Strain Hardening, Partial Annealed | Structural parts needing formability & moderate hardness |

| H34 | Strain Hardening Cold Working | Enhanced strength with bending or medium forming required |

| H36 | Strain Hardening, High Levels | High strength parts, weather fitting components |

| O | Annealed (Soft condition) | Maximum ductility for forming or welding tasks |

Complementary fabrication processes adhere strongly to standards, such as:

- ASTM B928 – The specification encompassing chemical composition and mechanical properties for marine aluminum plates including grade 5052.

- ISO 6361 (Aluminum and Aluminum Alloys - Sheets, Strips and Plates) tailoring international consistency.

- Marine Classification Society Rules such as the American Bureau of Shipping (ABS) and Lloyd's Register validate the plating suitability in seaworthy applications.

Chemical Composition Table: A Window into Alloy Behavior

| Element | Weight Percentage (%) | Role in Alloy |

|---|---|---|

| Aluminum (Al) | Balance | Primary base metal |

| Magnesium (Mg) | 2.2 – 2.8 | Increases strength and corrosion resistance |

| Chromium (Cr) | 0.15 – 0.35 | Enhances corrosion resistance and stability |

| Manganese (Mn) | 0.10 max | Refining while preserving color and strength |

| Iron (Fe) | 0.40 max | Typical allowed impurity within limits |

| Copper (Cu) | 0.10 max | Minimizing contributors of corrosion weakness |

| Silicon (Si) | 0.25 max | Impurity minimized to preserve mechanical properties |

These elements collaboratively shape the chemical integrity of 5052 aluminum plating, influencing everything from welding compatibility to long-term environmental endurance.

Robust Applications Powered by 5052 Marine Aluminum Plate

By balancing form, function, and longevity, 5052 marine aluminum plates prove essential for:

- Boat Hull Construction: Lightweight yet tough, reduces vessel displacement and enhances speed.

- Decking and Superstructures: Provides a solid, corrosion-resistant work surface above decks.

- Storage Tanks and Pipelines: Thanks to its purity and corrosion resistance, it’s a preferred material for fluid containment onboard.

- Marine Architectural Framework: Used in bridges, platforms, and offshore equipment requiring strength and resistance.

- Automotive and Aircraft Marine Hardware: Many hybrid water/land craft or amphibious vehicles leverage 5052 aluminum’s durability against elemental forces.