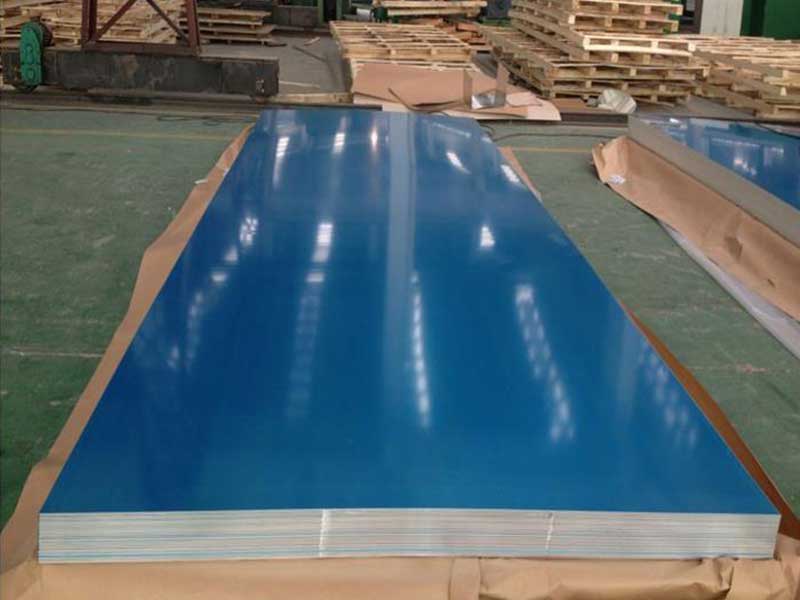

Aluminum Sheet Plate 1050

Aluminum Sheet Plate 1050 is a prime product in the aluminum family that is widely recognized for its excellent corrosion resistance, high thermal conductivity, and outstanding workability. Formed from the reputed 1000 series aluminum, this alloy provides a range of mechanical properties that make it suitable for various applications across diverse industries.

Features

High Purity: 1050 contains 99.5% aluminum content, ensuring it has very low impurity levels, contributing to its excellent characteristics.

Corrosion Resistance: Naturally resistant to corrosion, 1050 aluminum forms a protective oxide layer, increasing longevity.

Workability: This alloy offers excellent workability characteristics, allowing it to be easily bent, rolled, or machined.

Fabricability: Suitable for various manufacturing capabilities, such as welding, handling, and fabrication with forge abilities.

Thermal and Electrical Conductivity: It boasts a high level of heat and electrical conductance making it ideal for specific electronic applications.

Applications

Aluminum Sheet Plate 1050 is used in various industries due to its numerous beneficial properties, which include:

Food and Chemical Industries: Its high corrosion resistance makes it ideal for container use in chemical handling and bulk storage tanks.

Electrical Applications: With its excellent electrical conductivity, it is supplied for use in electrical transformer parts and connections.

Heat Exchangers: Its thermal properties allow for use in heat exchangers where temperature regulation is crucial.

Architectural Applications: An attractive and lightweight material suitable for architectural panels.

Welding Applications: Its navigational ease when welding provides utility for fabricators.

Technical Specifications

Chemical Composition

The following table summarizes the chemical composition of Aluminum Sheet Plate 1050.

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | ≥ 99.5% |

| Silicon (Si) | 0.25 max |

| Iron (Fe) | 0.40 max |

| Copper (Cu) | 0.05 max |

| Manganese (Mn) | 0.05 max |

| Magnesium (Mg) | 0.05 max |

| Chromium (Cr) | 0.10 max |

| Zinc (Zn) | 0.10 max |

| Titanium (Ti) | 0.05 max |

| Others | Each ≤ 0.03 and total ≤ 0.10 |

Technical Specifications

The following table presents specifications for Aluminum Sheet Plate 1050.

| Specification Line | Description |

|---|---|

| Alloy | 1050 |

| Temper | H14, H18, H22, H24, H28 |

| Density | 2.70 g/cm³ |

| Melt Point | 660 °C |

| Yield Strength | 70 MPa |

| Ultimate Strength | 90 MPa |

| Elongation at Break | 10% - 20% |

| Electrical Conductivity | 61% IACS |

| Thermal Conductivity | 235 W/m·K |

Aluminum Sheet Plate 1050 represents an essential material choice in several applications due to its high purity, excellent corrosion resistance, and adaptability to manifold fabrication techniques. Its versatility makes it invaluable within industries from chemical processes to construction. With superior thermal and electrical conductivity, this aluminum alloy solutions effectively addresses modern application needs specially where reliability and performance are paramount.

Discover Aluminum Sheet Plate 1050's features, applications, and technical specifications in our comprehensive guide. Ideal for the food, chemical, and electrical industries!