Anodized aluminum sheet 1050 1060 1070 1100 1200

Anodized aluminum sheets are essential materials in various industries due to their enhanced durability, aesthetic appeal, and excellent chemical properties.

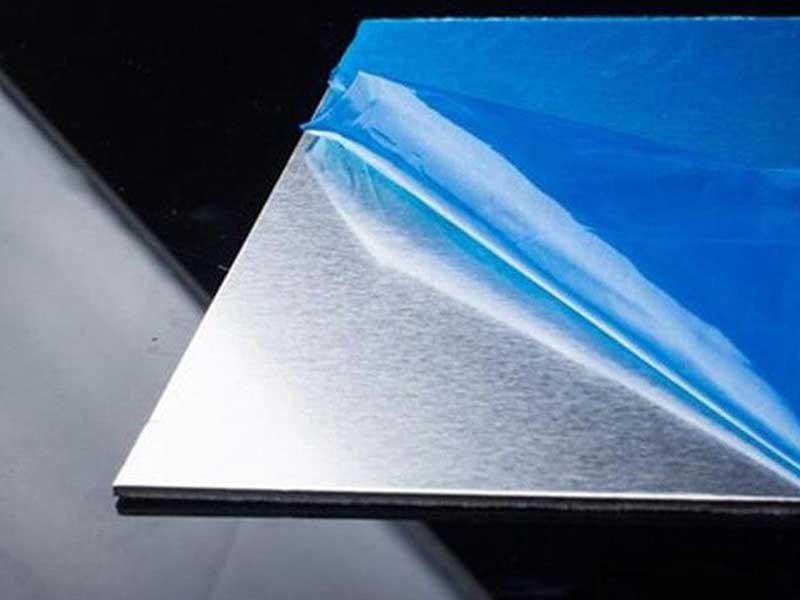

Anodization is an electrochemical process that forms a protective oxide layer on the aluminum surface. This treatment enhances corrosion resistance, improves wear properties, and provides coloring options, making the anodized aluminum sheet an excellent choice for numerous applications.

Features

- Enhanced Corrosion Resistance: Anodization provides a non-corrosive layer that protects the aluminum from harsh environmental conditions.

- Increased Surface Hardness: The anodized layer increases the hardness of the aluminum surface, making the material more durable against scratching and wear.

- Aesthetic Flexibility: Anodized surfaces can be easily dyed and brought varied colors, ensuring material versatility.

- Non-Toxic and Eco-Friendly: The anodization process and the materials involved are environmentally friendly, presenting no danger to health or the surroundings.

Technical Specifications

The performance of anodized aluminum sheets signifies their adoption across multiple sectors. Below is a table summarizing the important technical specifications for the anodized aluminum sheets made of the aforementioned alloys:

| Alloy | Thickness (mm) | Width (mm) | Length (mm) | Finish | Max Hardness (HV) |

|---|---|---|---|---|---|

| 1050 | 0.5 - 30 | 1000 - 2500 | 2000 - 6000 | Matte/Gloss | 85 |

| 1060 | 0.5 - 25 | 1000 - 2500 | 2000 - 6000 | Smooth/Pattern | 90 |

| 1070 | 1.0 - 20 | 1000 - 3000 | 2000 - 6000 | Pewter/Soft | 95 |

| 1100 | 0.5 - 20 | 1000 - 2500 | 2000 - 6000 | Rough/Anodized | 95 |

| 1200 | 0.3 - 20 | 1000 - 2500 | 2000 - 6000 | Brushed/Login | 99 |

Chemical Composition

The chemical composition of different alloys significantly impacts their strength, malleability, and suitability for specific applications. Below is a comprehensive table detailing the chemical composition of the listed alloy grades:

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1050 | 0.25 | 0.40 | 0.00 | 0.05 | 0.00 | 0.00 | 0.00 | 0.05 | Rest |

| 1060 | 0.25 | 0.40 | 0.00 | 0.05 | 0.00 | 0.00 | 0.00 | 0.05 | Rest |

| 1070 | 0.20 | 0.25 | 0.00 | 0.05 | 0.00 | 0.00 | 0.00 | 0.03 | Rest |

| 1100 | 0.95 | 0.40 | 0.05 | 0.05 | 0.00 | 0.00 | 0.00 | 0.10 | Rest |

| 1200 | 0.30 | 0.60 | 0.05 | 0.05 | 0.00 | 0.00 | 0.00 | 0.05 | Rest |

Alloy compositions indicate primary elements present while Al (%) is considered "remainder".

Mechanical Properties

mechanical properties highlights each alloy's strength, flexibility, and other critical characteristics. Below shows a relevant table for mechanical properties:

| Alloy | Yield Strength (MPa) | Ultimate Tensile Strength (Mpa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|

| 1050 | 70 | 100 | 30 | 30 |

| 1060 | 75 | 105 | 30 | 31 |

| 1070 | 85 | 116 | 20 | 32 |

| 1100 | 100 | 115 | 25 | 34 |

| 1200 | 95 | 123 | 25 | 35 |

Applications

Anodized aluminum sheets yield valuable utilizations across various markets. Below are distinguished applications relevant to each alloy grade:

- 1050: Used in applications requiring high thermal and electrical conductivity. It’s prevalent in the electronics and chemical processing industries.

- 1060: Typically signifies a processed application in roofing sheets and decorative pieces where aesthetics seamlessly integrate with durability.

- 1070: Known for its heat tolerance, favored in high-temperature engines and in applications within automotive environments or components.

- 1100: Used frequently in food and chemical handling due to its non-toxic traits, prevalent in kitchen equipment.

- 1200: This high-purity aluminum sheet works well for high-strength applications such as transporting pharma, medical device cleanliness, and battery offers components.

https://www.al-alloy.com/a/anodized-aluminum-sheet-1050-1060-1070-1100-1200.html