Brushed Aluminum Sheet Coil A1050 1060 1100

01/26 2026

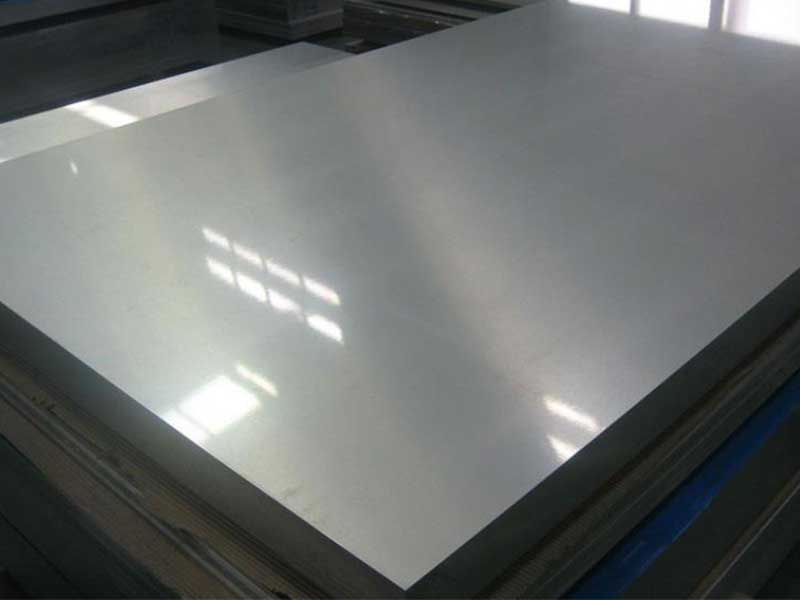

Brushed aluminum sheet coil in grades A1050, 1060, and 1100 offers a clean, modern metallic appearance combined with good formability and corrosion resistance. These grades belong to the 1xxx series of commercially pure aluminum, making them ideal for decorative, architectural, and light industrial uses where appearance and surface quality matter as much as function.

| Item | Description |

|---|

| Product form | Brushed aluminum sheet & coil |

| Alloy series | 1xxx (commercially pure Al) |

| Typical grades | A1050, 1060, 1100 |

| Temper availability | O / H12 / H14 / H16 / H18 / H24 / H26, others on request |

| Surface finish | Brushed / hairline / satin, single or double-sided |

| Thickness range | Approx. 0.2 – 6.0 mm (custom ranges available) |

| Width range | Approx. 20 – 2000 mm (depending on mill capability) |

| Coil inner diameter | Commonly 505 mm, 508 mm, 610 mm, customized on request |

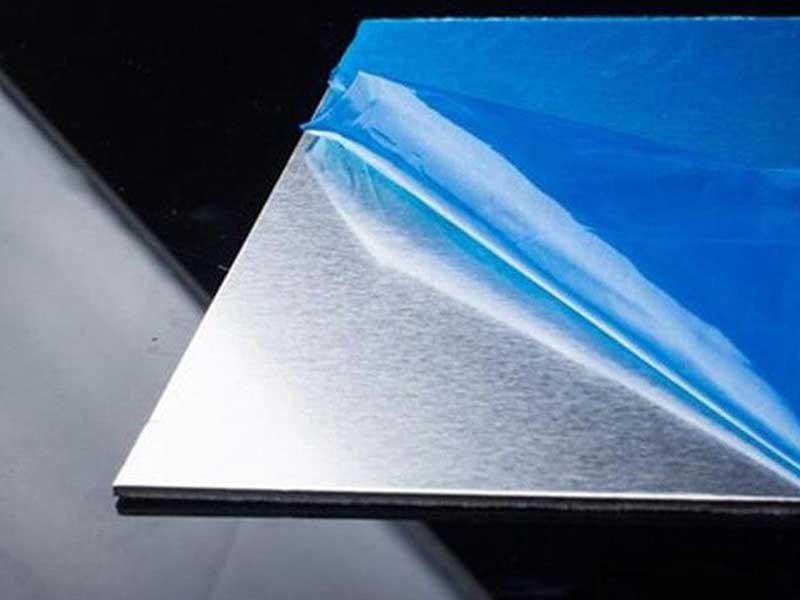

| Protective film | PE/PVC film, laser film, or custom films available |

Chemical Composition

These three alloys are all high-purity aluminum with minor differences in alloying elements, especially Fe, Si, and Cu. Values below are typical maximum limits; exact specs can vary slightly with standards (ASTM, EN, GB, JIS).

A1050 Chemical Composition (Typical, wt%)

| Element | Si | Fe | Cu | Mn | Mg | Zn | Ti | Others (each) | Others (total) | Al |

|---|

| Max % | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 | 0.10 | Balance |

1060 Chemical Composition (Typical, wt%)

| Element | Si | Fe | Cu | Mn | Mg | Zn | Ti | Others (each) | Others (total) | Al |

|---|

| Max % | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | 0.03 | 0.10 | ≥ 99.6 |

1100 Chemical Composition (Typical, wt%)

| Element | Si + Fe | Cu | Mn | Mg | Zn | Ti | Others (each) | Others (total) | Al |

|---|

| Max % | 0.95 | 0.05–0.20 | 0.05 | 0.05 | 0.10 | 0.05 | 0.05 | 0.15 | Balance |

Features of Brushed A1050 / 1060 / 1100

Surface and Aesthetic Advantages

| Feature | Description |

|---|

| Brushed / hairline texture | Linear grain pattern minimizes small scratches and fingerprints in daily use |

| Satin metallic sheen | Soft gloss, non-mirror, ideal for modern and minimalist design |

| Consistent color tone | Controlled rolling and surface treatment for uniform shade over large areas |

| Easy cleaning | Smooth but not mirror-slick surface; dust and stains wipe off easily |

| Film protection | PE/PVC film prevents damage during cutting, bending, and installation |

Material Performance

| Property Category | Characteristics |

|---|

| Purity | High aluminum content (≥ 99.0–99.6%), excellent corrosion resistance in normal atmospheres |

| Formability | Very good; suitable for bending, deep drawing, rolling, and simple forming |

| Weldability | Good for most conventional processes (TIG, MIG, resistance welding); low risk of hot cracking |

| Workability | Easy to cut, punch, shear, stamp, and router with standard equipment |

| Electrical conductivity | High conductivity due to purity; suitable for low-load conductive components |

| Non-magnetic | Suitable for applications requiring non-magnetic materials |

| Recyclability | 100% recyclable without loss of core properties |

Mechanical Properties (Typical)

Values vary with temper and thickness; table shows approximate room-temperature data.

| Alloy | Temper | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A50 (%) |

|---|

| A1050 | O | 60 – 95 | 20 – 30 | 25 – 40 |

| A1050 | H14 | 100 – 130 | 60 – 95 | 10 – 20 |

| 1060 | O | 60 – 100 | 20 – 30 | 25 – 40 |

| 1060 | H14 | 105 – 135 | 65 – 100 | 9 – 18 |

| 1100 | O | 70 – 110 | 25 – 35 | 25 – 35 |

| 1100 | H14 | 110 – 145 | 60 – 110 | 8 – 18 |

Brushed Surface Processing Options

| Parameter | Options / Description |

|---|

| Brushing direction | Longitudinal (coil direction), transverse, or cross-brushed |

| Grain type | Straight hairline, fine satin, coarse line, or customized textures |

| Roughness (Ra) | Typically 0.2 – 1.0 μm, adjustable depending on decorative demand |

| Sides | Single-sided brushed (standard) or double-sided brushed on request |

| Post-treatment | Cleaning, passivation, color anodizing (if required), protective film application |

The brushed finish is created by controlled mechanical abrasion, giving the surface a linear grain pattern. This softens reflections, hides minor handling marks, and delivers a high-end metallic look suitable for visible surfaces.

Dimensional and Supply Specifications

Standard Dimensions

| Parameter | Typical Range / Options |

|---|

| Thickness | 0.2 – 6.0 mm (ultra-thin foils or thicker plates available on request) |

| Standard width | 1000 / 1200 / 1250 / 1500 mm; custom widths up to ~2000 mm |

| Coil ID | 505 / 508 / 610 mm |

| Coil OD | Usually up to 1600 mm (subject to line limits) |

| Coil weight | Approx. 1 – 8 tons per coil, customizable |

| Flat sheet size | Common sizes: 1000 × 2000, 1220 × 2440, 1250 × 2500 mm, customized |

Tolerance and Flatness

| Item | Typical Control Level (Reference Only) |

|---|

| Thickness tol. | According to ASTM B209 / EN 485 / GB/T standards or customer specification |

| Width tol. | Typically ±1.0 mm or better, depending on width |

| Flatness | Controlled by tension leveling or stretcher leveling |

| Edge type | Mill edge or slit/deburred edge |

Typical Applications

Brushed A1050/1060/1100 finds use in both decorative and functional fields where lightweight, corrosion-resistant, and visually appealing metal is required.

Architectural & Interior Decoration

| Application Area | Examples |

|---|

| Wall cladding | Interior wall panels, lobby feature walls, elevator halls |

| Ceilings | Modular ceiling tiles, linear strip ceilings |

| Door & window trims | Frames, skirting, reveal trims, decorative caps |

| Elevator & escalator | Car walls, handrail side panels, ticket gate covers |

| Furniture & fixtures | Cabinet fronts, wardrobe doors, shelving faces, partition systems |

Appliances & Consumer Products

| Product Segment | Examples |

|---|

| Home appliances | Front panels for refrigerators, microwaves, air conditioners, ovens |

| Consumer electronics | Decorative covers for audio equipment, PC cases, control panels |

| Lighting | Lamp housings, reflectors (non-mirror), fixture trims |

| Kitchen & bathroom | Backsplashes, kick plates, decorative cladding, bath panel fronts |

Signage & Display

| Use Case | Examples |

|---|

| Sign boards | Corporate signage, building directories, safety signs |

| Display systems | Exhibition stands, retail shelving, brand walls |

| Nameplates & labels | Logo plates, instrument nameplates, control tags |

| POS / POP displays | Decorative face sheets, pylon trims, product display panels |

Light Industrial & Other Uses

| Segment | Examples |

|---|

| HVAC & ventilation | Decorative grilles, linear diffusers, vent covers |

| Transportation interior | Trim panels, luggage rack covers, instrument bezels (non-structural) |

| Electrical | Decorative covers for low-voltage boxes and panels |

| General fabrication | Custom enclosures, housings, art installations |

Advantages of Each Alloy Grade

While all three grades share similar appearance when brushed, each has small performance differences that help in choosing the right one.

| Alloy | Characteristic Focus | Typical Benefits |

|---|

| A1050 | General-purpose pure Al | Good formability, high ductility, economical choice for decorative panels |

| 1060 | Higher purity | Slightly improved conductivity and corrosion resistance, common in electrical & decorative uses |

| 1100 | Slightly alloyed with Cu | Better strength than 1050/1060 while maintaining good corrosion resistance and workability |

Selection often depends on required strength, ductility, and regional standard preferences rather than visible differences alone.

Handling, Fabrication, and Surface Care

| Aspect | Recommendations |

|---|

| Cutting | Shearing, laser, or CNC cutting with appropriate support to avoid surface dents |

| Bending | Use suitable radius to avoid cracking; softer tempers (O, H12) bend more easily |

| Welding | Clean the brushed surface before welding; re-brushing or blending may be needed |

| Surface protection | Keep PE/PVC film on during processing; remove after installation for best finish |

| Cleaning | Mild detergent and soft cloth; avoid strong alkalis or abrasive scouring pads |

Proper handling during transportation and fabrication helps preserve the fine brushed texture and consistent grain direction that are critical to appearance, especially on large visible surfaces.

Brushed aluminum sheet coil in A1050, 1060, and 1100 offers a balanced package of:

- Clean, uniform brushed aesthetics

- Lightweight, corrosion-resistant base metal

- Excellent formability and weldability

- Flexible dimensions and surface options

These qualities make it a reliable choice for architectural decoration, interior finishing, appliances, signage, and a wide range of consumer and light industrial products where both appearance and practicality are important.

1050

1060

1100

https://www.al-alloy.com/a/brushed-aluminum-sheet-coil-a1050-1060-1100.html