1050 1060 3003 5052 5083 6061 H14 H24 O Aluminum Sheet

When engineers and buyers talk about “1050 1060 3003 5052 5083 6061 H14 H24 O aluminum sheet,” they are really talking about a toolkit of aluminum solutions. Each alloy brings its own balance of strength, formability, corrosion resistance, and weldability; each temper (H14, H24, O) fine‑tunes that alloy for a specific job.

Instead of memorizing dozens of designations, it is more useful to understand how these alloys behave in the real world. Think of them as a spectrum: from very soft, pure aluminum for deep drawing, to marine‑grade plate for extreme environments, to structural sheet for load‑bearing components.

Below is a practical, application‑driven view of these common aluminum sheet alloys and tempers, with technical parameters and standards woven into how they are actually used.

Alloy Series: 1xxx, 3xxx, 5xxx, 6xxx

Aluminum alloys are grouped by their main alloying element.

- 1xxx series (1050, 1060): Commercially pure aluminum, excellent conductivity and formability, low strength.

- 3xxx series (3003): Aluminum–manganese, improved strength over pure aluminum, very good corrosion resistance.

- 5xxx series (5052, 5083): Aluminum–magnesium, high strength, excellent corrosion resistance, especially in marine and chemical environments.

- 6xxx series (6061): Aluminum–magnesium–silicon, heat‑treatable, good strength and machinability, widely used as a general structural alloy.

This chemical backbone determines core performance, while the temper (O, H14, H24, etc.) controls hardness and mechanical properties.

Tempers: O, H14, H24 – How “Soft” or “Hard” is the Sheet?

Temper describes the mechanical condition after processing.

- O (annealed): Fully soft, maximum ductility, lowest strength. Ideal for deep drawing, complex bending, spinning.

- H14 (half‑hard, strain‑hardened): Work‑hardened to about half of the maximum; good balance of strength and formability. Often used where moderate forming and higher stiffness are required.

- H24 (strain‑hardened and partially annealed): Slightly softer than full hard but stronger than H14 in many alloys; used where some forming is needed but dimensional stability and strength matter.

In practice:

- Choose O temper if the part requires severe forming or deep drawing.

- Choose H14 or H24 when you need stiffer panels, flatter sheets, and better dent resistance, with only moderate forming.

1050 and 1060 Aluminum Sheet – The Clean, Conductive Workhorses

1050 and 1060 are high‑purity aluminum (roughly 99.5–99.6% Al). They excel where electrical or thermal conductivity and corrosion resistance matter more than strength.

functions:

- Excellent electrical conductivity: ideal for busbars, transformer windings, electrical enclosures.

- High thermal conductivity: used in heat sinks, HVAC fins, and heat spreader plates.

- Outstanding formability: perfect for lamp reflectors, kitchenware, signage, and decorative panels.

Typical uses:

- Lighting reflectors and decorative trims (O or H14).

- Electrical busbars and foil stock (H24 or harder, depending on design).

- Chemical and food handling equipment where corrosion resistance and cleanliness are required.

Typical parameters:

- Thickness range: about 0.2–6.0 mm for sheet; up to 10 mm and above as plate.

- Standard width: commonly 1000–2000 mm; custom widths available.

- Surface: mill finish, brushed, embossed, or anodized.

3003 Aluminum Sheet – The Everyday Formable Alloy

3003 adds manganese to pure aluminum, boosting strength while keeping excellent formability and corrosion resistance. It is not heat‑treatable, so strength comes from cold working (H tempers).

functions:

- Better strength than 1xxx with similar formability: ideal for stamped and deep‑drawn parts.

- Very stable corrosion behavior: suitable for mild chemical and atmospheric environments.

- Good weldability and brazeability.

Typical applications:

- Roofing and cladding sheets.

- Air‑conditioning and refrigeration fins.

- Cookware bodies, kitchen panels, food and beverage storage.

- Fuel tanks and non‑pressurized fluid containers.

Typical tempers:

- O: deep‑drawn cookware, spun parts, and complex housings.

- H14/H24: roofing, sidings, panels, and lightweight structural sheets.

5052 Aluminum Sheet – High Strength and Marine‑Capable

5052 is an aluminum–magnesium alloy that stands out for its high strength, excellent resistance to seawater and industrial atmospheres, and very good formability for its strength level.

functions:

- Designed for environments where corrosion and strength both matter.

- Retains good bendability, even in thicker gauges.

- Welds cleanly with minimal loss of corrosion resistance.

Typical applications:

- Marine panels, boat hulls, deckplates, and cabin structures.

- Fuel tanks, truck and trailer bodies, pressure‑free vessels.

- Control panels, instrument enclosures, and chassis where stiffness is needed.

- Architectural components exposed to coastal atmospheres.

Common tempers:

- H32/H34 (not in your title but often used): balanced strength/formability.

- O: for deeply formed components like fuel tanks and complex covers.

- H14/H24: stiffer panels, brackets, and structural skins.

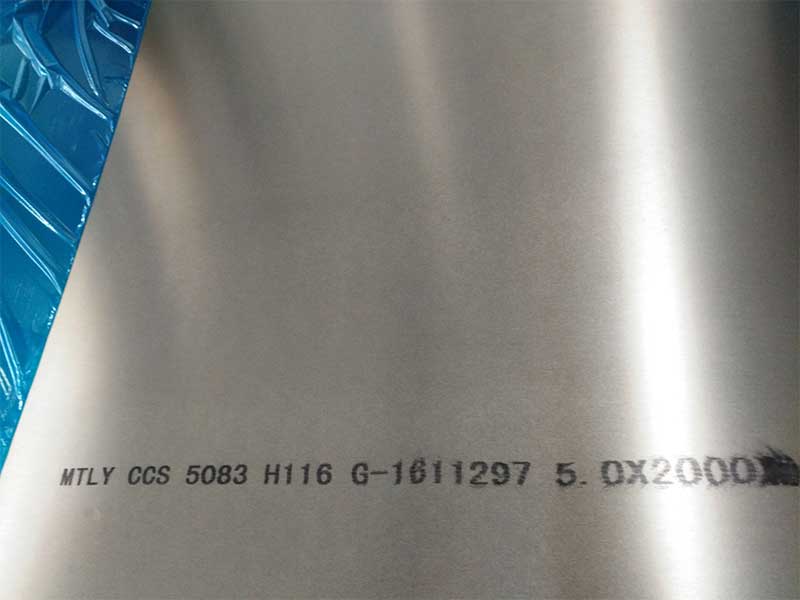

5083 Aluminum Sheet – Heavy‑Duty Marine and Cryogenic Grade

5083 takes magnesium to a higher level and introduces trace elements, giving significantly higher strength than 5052, while maintaining excellent marine and chemical resistance.

functions:

- High strength in non‑heat‑treatable category.

- Excellent resistance to seawater, brines, and many chemicals.

- Suitable for low‑temperature service (good toughness at cryogenic temperatures).

Typical applications:

- Shipbuilding: hulls, decks, superstructures, bulkheads.

- Offshore structures: platforms, gangways, access systems.

- Cryogenic and LNG tanks, pressure‑related cold storage systems.

- Heavy vehicle and trailer bodies that must resist corrosion and fatigue.

Typical parameters:

- Common in medium to heavy gauge sheet and plate (from about 2 mm up to thick plate).

- Often supplied in H116, H321 for marine service, but O or H tempers are also used for forming operations.

6061 Aluminum Sheet – The Versatile Structural Alloy

6061 is a heat‑treatable aluminum–magnesium–silicon alloy. While often seen as plate and extrusions, 6061 sheet brings structural strength and machinability to flat products.

functions:

- Good mechanical strength and stiffness, especially in T temper (T6, T651).

- Good machinability and acceptable corrosion resistance.

- Suitable for components that need both strength and precision machining.

Typical applications:

- Machine bases, structural panels and frames.

- Automotive and motorcycle parts, suspension brackets, adapter plates.

- Aerospace fixtures, jigs, and non‑critical aircraft components.

- Industrial covers, platforms, high‑stiffness mounting plates.

Note: For heavy forming, O or T4/T6 with subsequent forming/heat treatment strategies may be used. For general sheets, buyers often combine 6061 with H tempers when they prioritize specific fabrication processes, but strictly speaking, 6061’s main strength advantage emerges in T tempers rather than H.

Implementation Standards and Typical Specifications

These alloys are commonly produced under standards such as:

- ASTM B209 – Aluminum and Aluminum‑Alloy Sheet and Plate

- EN 485 / EN 573 – Aluminum and aluminum‑alloy sheets, strips, and plates

- GB/T 3880 – Aluminum and aluminum alloy plates and strips (China standard)

specification points customers typically confirm:

- Alloy and temper (for example 5052‑H32, 3003‑H14, 1060‑O).

- Thickness tolerance and flatness (critical for laser cutting, deep drawing, and panel assembly).

- Surface quality (mill finish, anodizing quality, polyester‑coated, etc.).

- Mechanical property ranges (yield strength, tensile strength, elongation).

Typical Chemical Composition (Mass %)

Values below are typical ranges; exact limits follow the relevant standard.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | – | ≤0.05 | ≤0.03 | ≥99.50 |

| 1060 | ≤0.25 | ≤0.35 | ≤0.05 | ≤0.03 | ≤0.03 | – | ≤0.05 | ≤0.03 | ≥99.60 |

| 3003 | ≤0.60 | ≤0.70 | ≤0.05–0.20 | 1.0–1.5 | – | – | ≤0.10 | – | Balance |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | ≤0.03 | Balance |

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.40–1.0 | 4.0–4.9 | 0.05–0.25 | ≤0.25 | ≤0.15 | Balance |

| 6061 | 0.40–0.80 | ≤0.70 | ≤0.15–0.40 | ≤0.15 | 0.8–1.2 | 0.04–0.35 | ≤0.25 | ≤0.15 | Balance |

This chemistry directly shapes performance: magnesium boosts strength and corrosion resistance; manganese improves strength and work‑hardening behavior; silicon and magnesium together enable heat‑treatable 6061.

Choosing the Right Alloy–Temper Combination

Viewed as a toolkit, these common combinations are especially useful:

- 1050/1060‑O: For deep‑drawn, highly formed components, reflectors, cookware bodies.

- 1050/1060‑H14/H24: For conductive components and flat panels that need light stiffness.

- 3003‑O/H14: For general‑purpose sheet metal, roofing, HVAC fins, and food‑grade containers.

- 5052‑H32/H34/H24: For marine hardware, transportation panels, enclosures requiring better strength and corrosion resistance.

- 5083‑H116/H321/O: For shipbuilding, offshore platforms, and cryogenic equipment.

- 6061 (typically T6 plate and sheet): For structural parts requiring machining and higher mechanical strength.

By matching environment (indoor, outdoor, coastal, chemical), forming requirement (simple bend or deep draw), and strength level, you can quickly narrow down the right alloy and temper.

https://www.al-alloy.com/a/1050-1060-3003-5052-5083-6061-h14-h24-o-aluminum-sheet.html