Embossed aluminum foil for tin foil paper for packaging

When we think of tin foil paper, generally, the image that comes to mind is a smooth, shiny sheet of aluminum used to wrap food for storage or cooking. Yet, not all aluminum foils are created equal. In particular, embossed aluminum foil brings a unique texture and a set of benefits that extend well beyond basic packaging.

What Is Embossed Aluminum Foil?

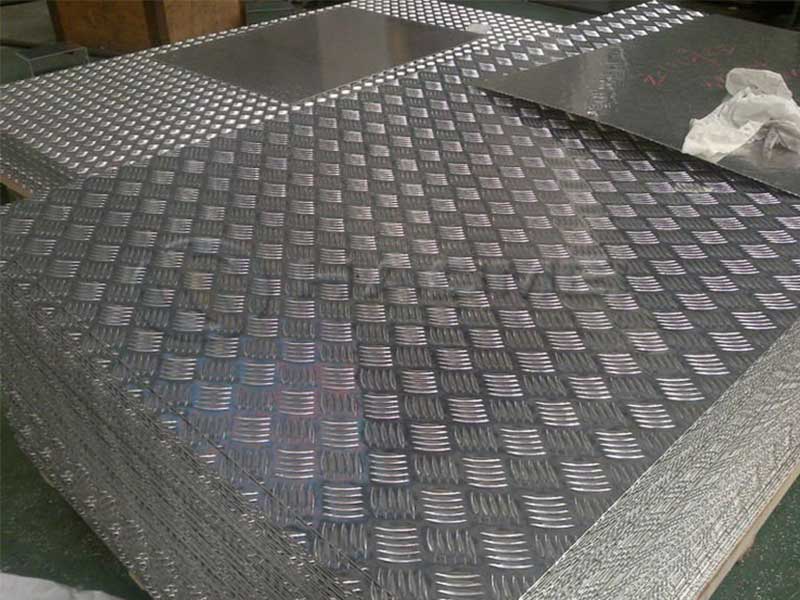

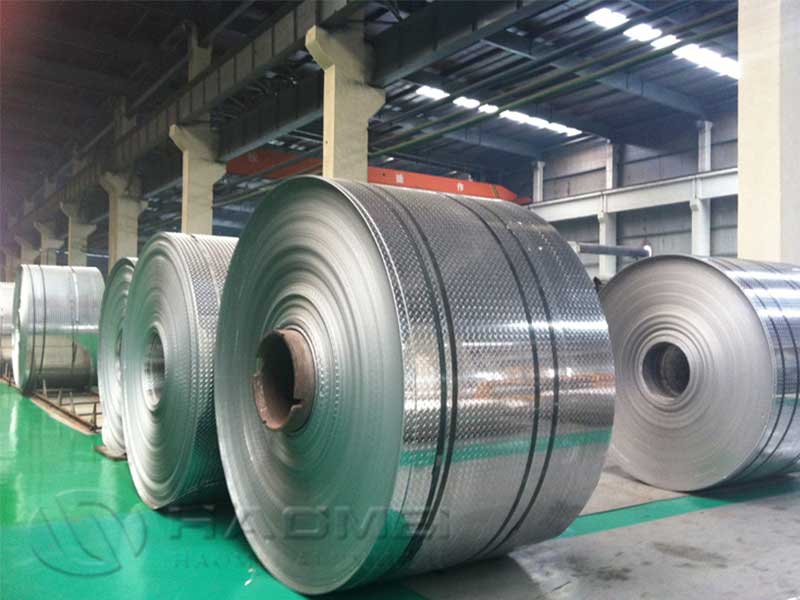

Embossed aluminum foil undergoes a mechanical process where patterns—often in the form of dimples, cross-hatches, or other textured designs—are pressed onto its surface. This contrasts with traditional smooth aluminium foil, created by rolling pure aluminum ingots until extremely thin, and then cutting or spooling them as sheets or rolls.

Typical commercial aluminum foils used for packaging belong to alloys such as 1100 (essentially pure Al with 99%+) or the slightly stronger 8011 alloy. Embossing can be applied across drammittable thicknesses, ranging commonly from 6 microns up to 20 microns or beyond.

The embossing pattern isn’t merely for aesthetics; it critically alters how the foil behaves in use.

Why Emboss Aluminum Foil for Packaging?

1. Enhanced Barrier and Insulation Properties

The embossing process slightly dims the foil’s surface, diffusing light more effectively to prevent metal photon penetration—useful when blocking UV radiation in light-sensitive packaging. More importantly, the tiny raised patterns reduce the contact surface between stacked foil layers in packaging lines and inside rolls, which improves the airtight seal by promoting micro-binding points upon folding.

Additionally, the air pockets created by embossing act as mild insulation layers. Wrapping hot or cold food in embossed foil helps maintain temperature longer compared to smooth foil packages.

2. Increased Mechanical Strength and Tear Resistance

Aluminum foil sheets spiral-wrapped with identical smooth layers can tend to stick excessively due to high surface smoothness. Embossed textures lessen this problem by decreasing surface contact, which also helps reduce distortion or wrapping tears. This facilitates easier unfolding by the consumer without catastrophic ripping.

Embossing technology can strengthen the foil by strain hardening from cold working, effectively improving the final product's ultimate tensile strength and elongation characteristics without adding weight.

3. Improved Consumer Handling and Aesthetics

The haptic feedback of embossed aluminum foil gives a tactile grip, addressing the slippery feel of smooth foil often criticized by users—particularly when handling oily or wet foods. The texture makes tearing or folding simpler and more intuitive.

Furthermore, embossed designs provide useful branding or informational markers. Manufacturers can employ embossing for logos, measurements (such as folding guides), or patterning that sets competitors apart on the shelf visually while conveying quality.

Typical Alloy and Temper Specifications for Embossed Foil

Most embossed packaging foils are made from alloy 8011-H14 or 8011-O temper, giving a balance between softness for embossing machinery and strength for handling.

| Parameter | Typical Range | Standard |

|---|---|---|

| Alloy | 1100 or 8011 | ASTM B479, EN573-3 |

| Temper | H14 (strain hardened) | ASTM B547 |

| Thickness | 6 - 20 µm | ISO 2197 |

| Ultimate Tensile Strength | 70 - 120 MPa | ASTM E8 standard |

| Elongation at Break | 1% - 6% | ASTM E8 standard |

| Surface Finish | Embossed textured surface | Custom patterns |

| Chemical Composition (8011) | Al balance, Fe < 0.4%, Si < 0.3% | ASTM B479, EN573-3 |

Embossing Methods and Patterns

Embossing can be done using several practical approaches:

- Roller embossing, where steel rollers carry the positive and negative patterns, is the most widespread method.

- Stamp embossing, ideal for small batch customization, uses individual presses.

- Laser embossing, although costly, allows highly detailed patterns.

Common embossing patterns in tin foil include hexagonal honeycomb, grid grids, cross hatch, fine dot textures, and wave designs. These patterns influence performance characteristics such as sealing quality, stiffness, and heat retention.

Environmental and Practical Advantages

From a sustainability viewpoint, embossed foil helps reduce total aluminum usage since a stronger, textured thin foil can substitute thicker smooth-grade sheets, leading to decreased material consumption and waste. This aligns well with modern packaging’s push toward lighter, eco-friendlier solutions without compromising functional qualities.

In recycling streams, embossed foil may also aid sorting equipment recognition due to different reflectance patterns, enhancing aluminum recycling efficacy.

https://www.al-alloy.com/a/embossed-aluminum-foil-for-tin-foil-paper-for-packaging.html