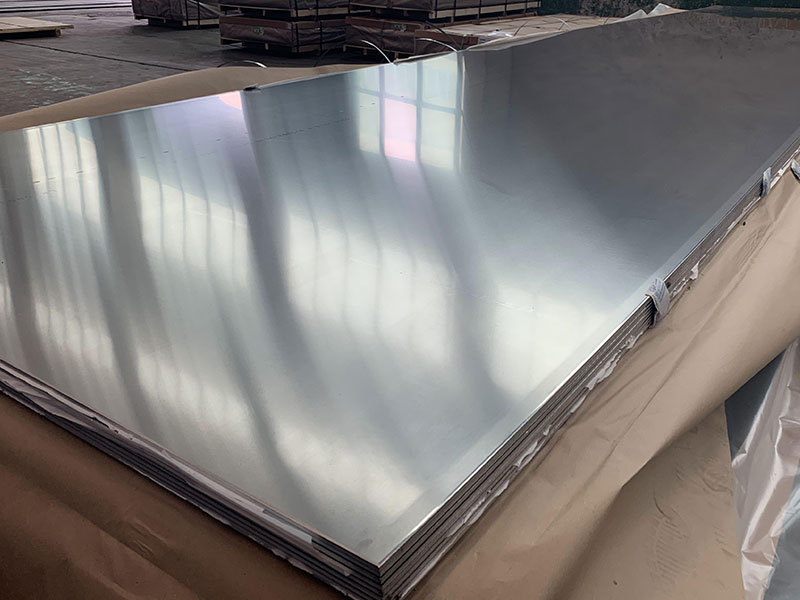

5086 H116 aluminum sheet for shipbuilding

In the sophisticated arena of shipbuilding, material selection transcends mere structural needs—requiring a harmonic balance of robustness, durability, fabrication ease, and resilience to a relentlessly corrosive environment. Among the panoply of aluminum alloys, 5086 H116 aluminum sheet emerges as a distinguished contender, offering specialized features tailored to the rigorous demands of marine vessels.

5086 Alloy and Its Unique H116 Temper

5086 is an aluminum-magnesium alloy noted for its superior corrosion resistance and high strength-to-weight ratio relative to typical aluminum lagers used in structural applications. Its nominal chemical composition (in weight percent) includes:

| Element | Min (%) | Max (%) |

|---|---|---|

| Magnesium (Mg) | 4.0 | 4.9 |

| Manganese (Mn) | 0.2 | 0.7 |

| Chromium (Cr) | 0.05 | 0.25 |

| Iron (Fe) | - | 0.5 |

| Silicon (Si) | - | 0.4 |

| Copper (Cu) | - | 0.1 |

| Zinc (Zn) | - | 0.25 |

| Aluminum (Al) | Balance |

H116 temper designates a specialized strain-hardened condition unique to marine and corrosive service: it is strain-hardened to a certain strength level while having enhanced and documented resistance against both corrosion and exfoliation. This distinguishes it from the more common H32 or H34 tempers widely used in general alloy 5086 sheets.

Technical Highlights of 5086 H116 aluminum sheets:

| Property | Specification |

|---|---|

| Tensile Strength (Ultimate) | 290–350 MPa |

| Tensile Strength (Yield 0.2%) | ≥ 200 MPa |

| Elongation (in 2 inches) | ≥ 12% |

| Resistance to Corrosion (Seawater Immersion) | Outstanding |

| Exfoliation Corrosion Resistance | High |

| Density | ~2.66 g/cm³ |

| Thermal Conductivity | ~138 W/m·K |

Process Parameters and Standards

- Processing standard: AMS 4047 (for marine-grade Al-Mg alloy sheet), MIL-DTL-46027E for aluminum alloys used in ship construction.

- Sheet thickness: Ranges broadly from 1.5mm to 25mm and can be customized per structural requirements.

- Forming: Cold work strain hardening (to meet H116 designation), recommended pre- and post-form thermal stress relief to optimize corrosion resistance.

- Welding: Compatible with gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW), though post-weld annealing may be necessary depending on joint design.

Let us approach the sea-faring applications through the lens of material biomechanics and the physics of marine corrosion processes.

Strength & Toughness Synergism: Behavior in Dynamic Wave Loads

Baltic testing and field experience reveal that 5086 H116 exhibits strain-rate dependent toughness superior to the ordinary-strength aluminum alloys. This lends early crack retardation under fluctuating vibrational impacts (e.g., wave-induced pressures). The H116 temper corners the proverbial “strength-ductility trade-off” finely: strengthening through strain-hardening while retaining ductility by controlling microstructural banding.

This biomechanical attribute means ship hulls composed of 5086 H116 conform elastically and plastically to intermittent stresses without microcrack initiation, substantially improving fatigue life. The thick and thin hull regions respond ideally due to the superior uniform elongation.

Corrosion Resistance as an Electrochemical Shield

The ocean is an electrochemical battlefield whereby chloride ions aggressively attack most metals. 5086 H116’s high Mg content fortifies its passivation film — a tight, self-healing aluminum oxide layer enhanced by selective alloying with Chromium and Manganese.

Field immersion trials in synthetic seawater demonstrated that 5086 H116 alloy sheet completed over 10,000 hours with minimal pitting and exfoliation, an insidious laminar metal degradation common with high-Mg alloys without the H116 temper's careful processing. This translates to longer overhaul periods and minimal corrosion holes in plates subjected to tidal and spray rotted zones — a decisive economic effect in maintenance-intensive naval craft and commercial ships alike.

Formability Paired with Weld Fusion Stability

Often, marine fabricators encounter a collision: to form with mini-defects threatening ship integrity or to weld robust joints whose heat affect zone (HAZ) softness fosters corrosion blind-spots.

5086 H116 navigates this particular trade skilfully. With a sufficiently high elongation (≥12%), it allows bending and complex forming contours essential to hull panel construction. Post incorporation into plate structures, weld joints respect prescribed Type IV ratings regarding corrosion in the heat-afflicted zone when conventional arc techniques are controlled accurately, aligning with AWS D17.2 compliances.

Critical Applications of 5086 H116 Aluminum Sheet in Shipbuilding

1. Hull Panels and Deck Plating

Waste and weight reduction for fuel efficiency demand both thin gauge and massive oval heavy plate grades. This alloy’s strain-hardening schemes deliver scalable strength in plates that resist propagation of cracks arising from hull stress distribution during rough seas nor suffer from the "metal sickness" caused by long-term saltwater exposure.

2. Superstructure and Offshore Platforms

Aluminum superstructures confer lighter center-of-gravity distributions enhancing vessel stability. The problem is by being dire-exposed, atmospheric gratings and support structures can endure oxidative breakdown; here, 5086 H116's superior atmospheric and splash-zone corrosion imperviousness ensure minimal preventive downtime and lifecycle cost savings.

3. Marine Tanks & Bulkheads

Holding fluids chemically related or essential for ship operations—the anti-corrosive veracity combined with extraordinary ban against local stress corrosion cracking (SCC) bolsters seaworthiness when stored liquids include potable water, greywater or even bilge fuel traps within highly stressed structural constituent bays.

Summation: The Technical-Environmental Harmony in 5086 H116

Unfolding beyond basic aluminum sheet, the 5086 H116 aluminum sheet effectuates a blend of metal physics and corrosion science specifically fashioned to profit marine and offset-making industries at varying scales—mercantile, military, and eco-purposeful alike.

- The alloy Supplemented by the bespoke heat/strain hardening process rawly upholds structural fortitude without forfeiting necessary ductility or weld stability.

- H116 temper combats one of shipbuilders' scourges by taking enzymatic deterioration off the material concern list.

- Multimodally receptive to standard fabrication techniques combined with advanced standards, the alloy introduces noticeable functional and economic uplift for protracted service periods.

In essence, for maritime endeavors echoing challenges of constant motion, aqueous born corrosion, and extended component-life targeting—the use of 5086 H116 stands astutely informed and assured.

For fabricators, marine architects, and engineers evaluating the right material footprint in expanding the capability ceiling of next-generation vessels, embracing 5086 H116 alloy first-hand may be one of the most decisive, longevity-optimizing choices available.

https://www.al-alloy.com/a/5086-h116-aluminum-sheet-for-shipbuilding.html