Mirror Finish Alloy Metal Anodized Aluminium

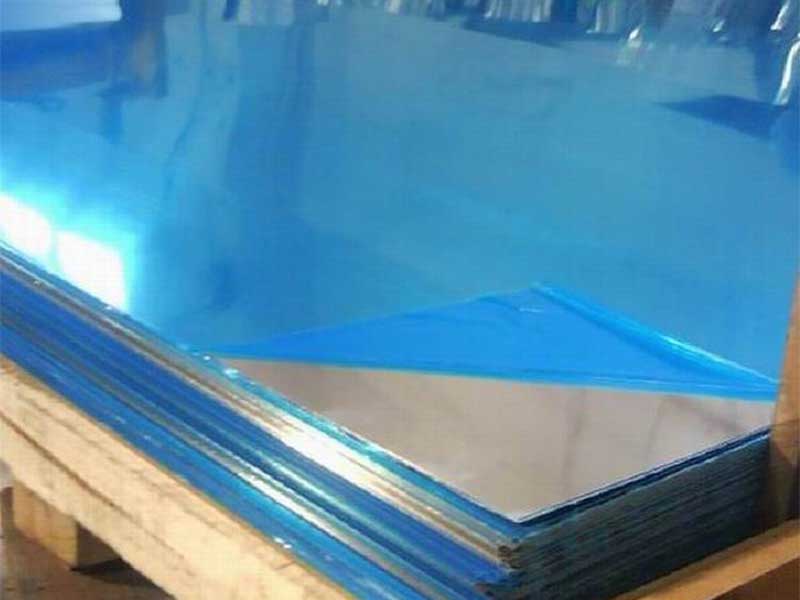

The mirror finish alloy metal anodized aluminum is a premium metallic material renowned for its exceptional aesthetic appeal, corrosion resistance, and versatility in various applications.

Features

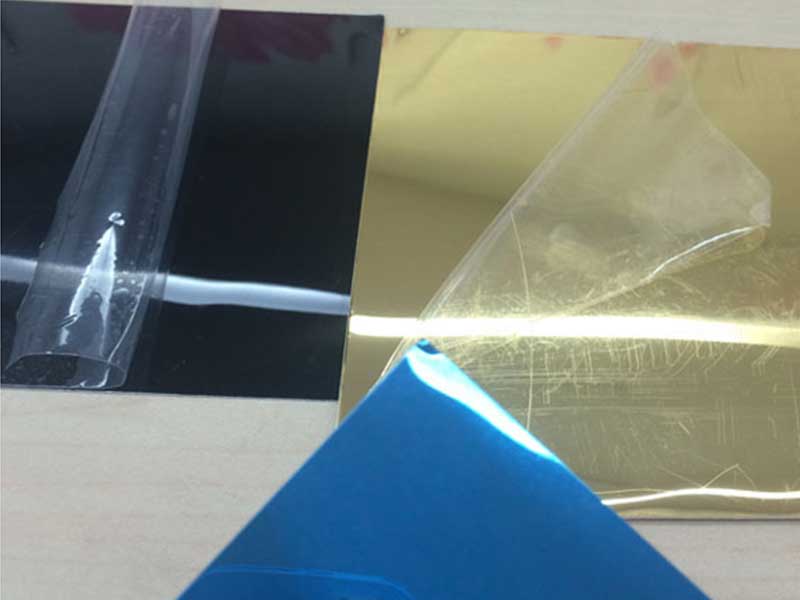

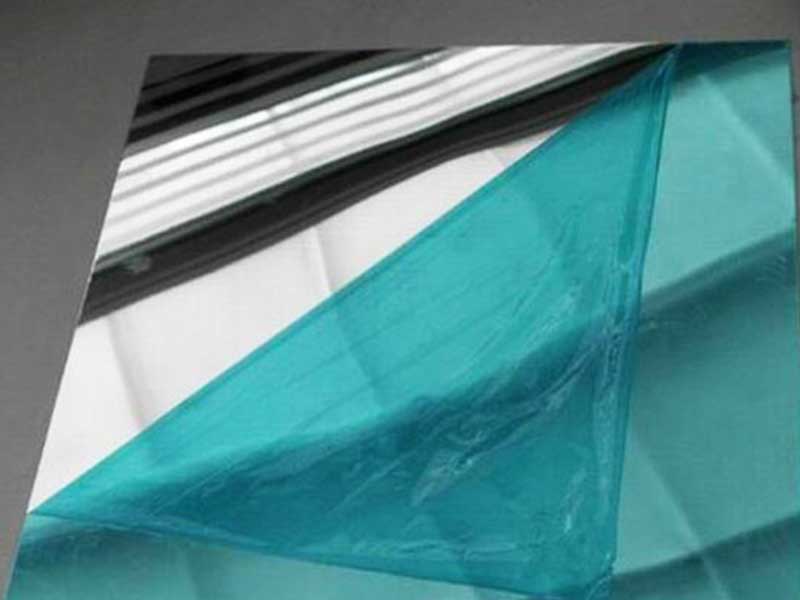

- Aesthetic Appeal: The highly reflective surface gives an elegant mirror-like finish that enhances the exterior appearance of products.

- Corrosion Resistance: Anodic oxidation creates a protective layer that significantly improves resistance to weathering and corrosion.

- Durability: The anodized process adds hardness to the surface, making it resistant to scratches and warrants longevity for indoor and outdoor use.

- Customization: Available in various colors and finishes, allowing manufacturers to achieve striking designs in various architectural and industrial contexts.

- Lightweight: Made from aluminum, it is significantly lighter than steel, which can reduce shipping costs and ease installation.

Applications

Mirror finish alloy metal anodized aluminum is used across various industries, including:

- Architectural Facades: Used in building exteriors where aesthetic and functional requirements are prominent.

- Automotive Industry: Utilized in vehicle interiors and exteriors for light weighting and design.

- Consumer Electronics: Utilized in the cases for phones and computers, enhancing aesthetics while providing a degree of protection.

- Decorative Items: Commonly included in modern art frames, mirrors, and various home decor products.

- Signage: Effective for eye-catching and long-lasting signage materials, especially in high-traffic spaces.

Technical Specifications

Chemical Composition

| Element | Symbol | Composition (%) |

|---|---|---|

| Aluminum | Al | 99.9 |

| Silicon | Si | Trace |

| Iron | Fe | 0.4 |

| Copper | Cu | 0.1 |

| Manganese | Mn | 0.1 |

| Magnesium | Mg | 0.1 |

| Zinc | Zn | 0.1 |

| Titanium | Ti | Trace |

| Other Elements | - | Trace |

Technical Specifications

| Property | Value |

|---|---|

| Alloy Series | 5000, 6000 |

| Tempers | H14, H24, H32 |

| Finish | Mirror anodized |

| Thickness | 0.3 to 5.0 mm |

| Width | Custom (Upto 1500 mm) |

| Standard Size | 1220 x 2440 mm |

| Yield Strength | > 200 MPa |

| Elongation | > 12% |

| Hardness (Brinell) | > 70 HB |

| Reflectance | > 90% |

Alloy Tempering Conditions

Mirror finish alloys are available in various temper conditions, including:

| Alloy Temper | Cooling Method | Typical Applications |

|---|---|---|

| H14 | Controlled Tempering | Quick deployment in construction open spaces |

| H24 | Solution Heat Treatment | Precision components in electronics |

| H32 | Natural Aging | Structural elements in buildings |

https://www.al-alloy.com/a/mirror-finish-alloy-metal-anodized-aluminium.html