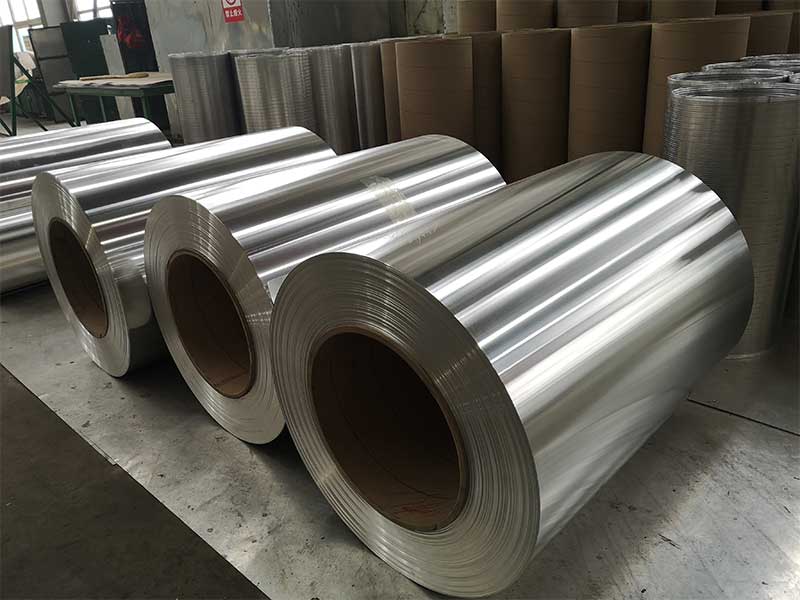

Pre-painted Aluminium Coil

Pre-painted aluminium coil is a highly versatile product widely utilized in various industries due to its excellent combination of lightweight, durability, and aesthetic appeal. This product involves applying paint or a coating on aluminium sheets or coils to provide added value and functionality. Below is an overview of the features, applications, and technical specifications of pre-painted aluminium coils.

Features

- Corrosion Resistance: The pre-painted surface enhances the natural protective properties of aluminium against corrosion.

- Weather Resistance: Designed to withstand aesthetic degradation from the elements, maintaining its brightness and color vibrancy.

- Lightweight: Significantly lighter than steel, facilitating easier handling and installation.

- Ease of Fabrication: Can be easily fabricated by cutting, bending, and moulding due to its excellent workability.

- Customizable Colors and Finishes: Available in a wide range of colors and finishes, including matte, glossy, and metallic textures.

- Eco-friendly: Often produced using sustainable materials and processes, contributing to the reduction of environmental impact.

Applications

Pre-painted aluminium coils find their use across various sectors due to their lightweight and durable nature. Some of the most common applications include:

- Building and Construction: Panels for roofing, facades, and wall cladding.

- Interior Applications: Ceiling tiles and decorative wall panels that require aesthetic appeal combined with function.

- Transportation: Interior finishes for trains, buses, and caravans.

- Signage: Durable external signs and displays in public areas.

- Home Appliances: Decorative coatings for refrigerators, washing machines, and other household products.

Technical Specifications

The performance of pre-painted aluminium coils can be specified through various technical parameters and chemical properties. Below are the specifications:

Table 1: Technical Specifications

| Parameter | Value |

|---|---|

| Alloy Type | 1050, 1100, 3003 |

| Thickness Range | 0.2 mm to 1.5 mm |

| Width | 100 mm to 1650 mm |

| Length | 1000 mm to 6000 mm |

| Finish | PE (Polyester), PVDF |

| Coating Thickness | 15-30 microns |

| Temper Conditions | H14, H24 (for light milling), H44 (for heavy milling) |

| Weight | 2.7 g/cm³ |

Table 2: Chemical Composition

| Alloy Type | Chemical Composition (Weight %) |

|---|---|

| 1050 | Al: min 99.5%, Si: max 0.25%, Fe: max 0.2% |

| 1100 | Al: min 99%, Cu: max 0.15%, Si: max 0.25% |

| 3003 | Al: min 97.5%, Mn: 1.0-1.5%, Cu: max 0.2% |

Table 3: Performance Features

| Feature | Description |

|---|---|

| Tensile Strength (MPa) | 145 - 250 |

| Elongation % | 10 - 20 |

| Yield Strength (MPa) | 90 - 120 |

| Flexibility (Flexural Modulus) | 70,000 - 80,000 MPa |

| UV Resistance | Passed ASTM G155, accelerated weather test. |