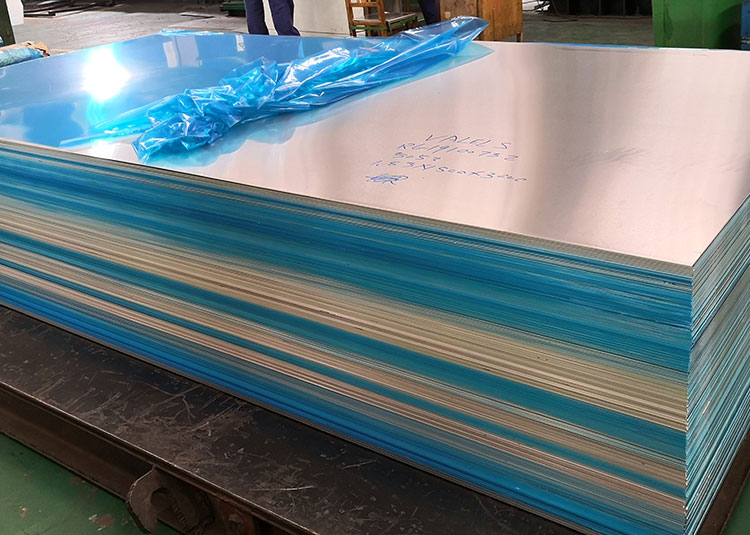

Chemical Compositions Marine Aluminum Sheet | |||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al | |

| Each | Total | ||||||||||

| 5A01 | Si+Fe≤0.40 | ≤0.10 | 0.30~0.70 | 6.0~7.0 | 0.10~0.20 | ≤0.20 | ≤0.15 | ≤0.05 | ≤0.15 | Remain | |

| 5454 | ≤0.25 | ≤0.40 | ≤0.10 | 0.50~1.0 | 2.4~3.0 | 0.05~0.20 | ≤ 0.25 | ≤ 0.20 | ≤0.05 | ≤0.15 | Remain |

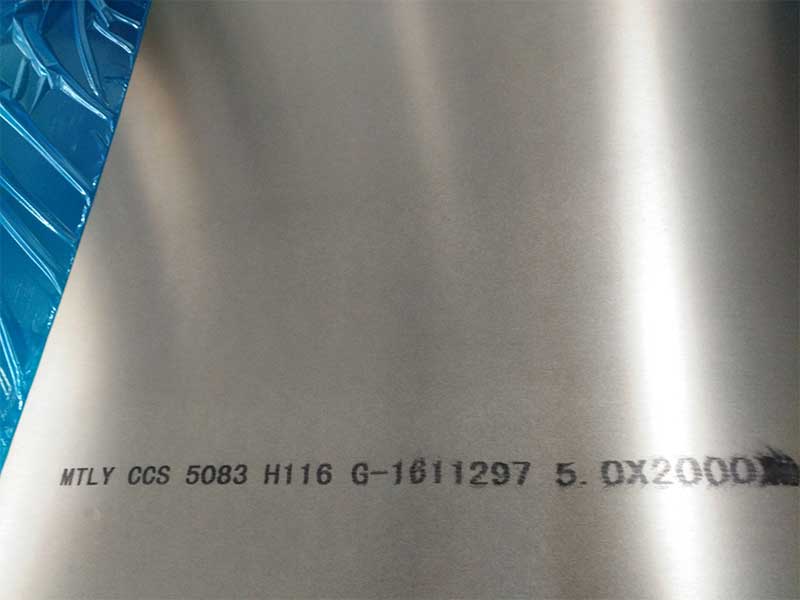

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.40~1.0 | 4.0~4.9 | 0.05~0.25 | ≤ 0.25 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 5383 | ≤0.25 | ≤0.25 | ≤0.20 | 0.7~1.0 | 4.0~5.2 | ≤ 0.25 | ≤ 0.40 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 5059 | ≤0.45 | ≤0.50 | ≤0.25 | 0.6~1.2 | 5.0~6.0 | ≤ 0.25 | 0.40~0.90 | ≤ 0.20 | ≤0.05 | ≤0.15 | Remain |

| 5086 | ≤0.40 | ≤0.50 | ≤0.10 | 0.20~0.70 | 3.5~4.5 | 0.05~0.25 | ≤ 0.25 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 5456 | ≤0.25 | ≤0.40 | ≤0.10 | 0.50~1.0 | 4.7~5.5 | 0.05~0.20 | ≤ 0.25 | ≤ 0.20 | ≤0.05 | ≤0.15 | Remain |

| 5754 | ≤0.40 | ≤0.40 | ≤0.10 | ≤ 0.50 | 2.6~3.6 | ≤ 0.30 | ≤ 0.20 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 6005A | 0.50~0.90 | ≤0.35 | ≤0.30 | ≤ 0.50 | 0.4~0.7 | ≤ 0.30 | ≤ 0.20 | ≤ 0.10 | ≤0.05 | ≤0.15 | Remain |

| 6061 | 0.40~0.80 | ≤0.70 | 0.15~0.40 | ≤ 0.15 | 0.8~1.2 | 0.04~0.35 | ≤ 0.25 | ≤ 0.15 | ≤0.05 | ≤0.15 | Remain |

| 6082 | 0.7~1.3 | ≤0.50 | ≤0.10 | 0.40~1.0 | 0.6~1.2 | ≤ 0.25 | ≤ 0.20 | ≤ 0.10 | ≤0.05 | ≤0.15 | Remain |

Mechanical Properties

6082 aluminum offers a robust combination of mechanical properties, making it suitable for a wide range of applications:

Tensile Strength: Approximately 310-340 MPa

Yield Strength: Around 260-280 MPa

Elongation: Typically about 10-12%, indicating good ductility

Corrosion Resistance

6082 aluminum exhibits excellent corrosion resistance, particularly in atmospheric conditions, which is vital for outdoor and structural applications.

Machinability

One of the standout features of 6082 aluminum is its excellent machinability, making it highly desirable for complex component manufacturing.

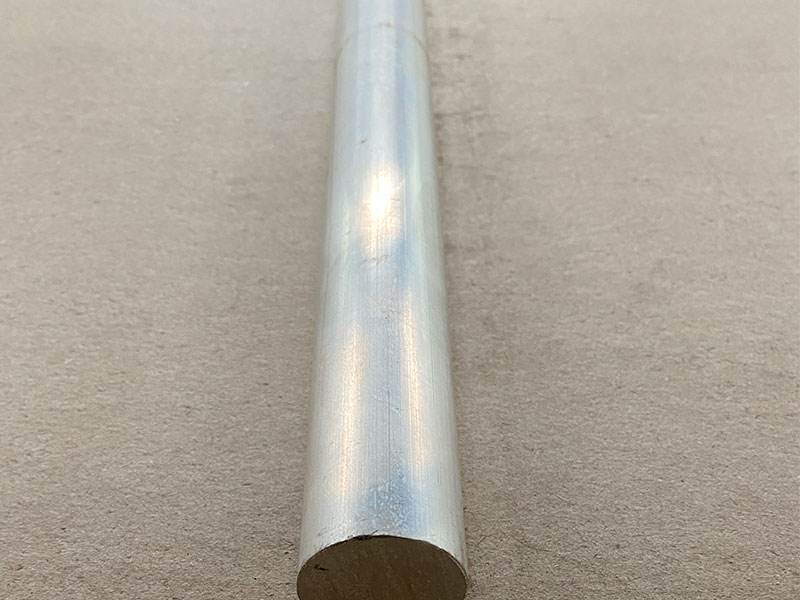

Applications of Marine 6082 Aluminum Rod & Bar

Thanks to their corrosion-resistant nature, 6082 aluminum rods and bars are employed in marine environments for applications such as boat fittings and marine structures, where they can withstand harsh conditions over time.

Advantages of Using 6082 Aluminum Rod & Bar

High Strength: Offers superior load-bearing capability, making it suitable for demanding applications.

Corrosion Resistance: Ensures longevity and reliability, especially in outdoor and marine environments.

Excellent Machinability: Provides ease of machining, reducing manufacturing time and costs for complex parts.

Weldability: 6082 aluminum is readily weldable, which facilitates ease of fabrication and assembly.

Recyclability: As with other aluminum alloys, it is fully recyclable, promoting sustainability and reducing environmental impact.

Certificate