1050-h14 Blue Film Cladding Mirror Aluminum Coil

In the world of metals, aluminum stands as a paragon of versatility, offering an exceptional balance of strength, weight, corrosion resistance, and aesthetic appeal. Among the spectrum of aluminum alloys and treatments, the 1050-H14 blue film cladding mirror aluminum coil emerges as a specialized product whose practical advantages often fly under the radar.

1050-H14 Aluminum Alloy

The base of this product is the 1050 aluminum alloy, classified under the 1xxx series, known for its purity (99.5% aluminum minimum) and superior corrosion resistance.

The 1050-H14 blue film clad mirror aluminum coil presents unique challenges compared to standard aluminum coils. The "blue film," a result of a specific anodization process, provides enhanced reflectivity and corrosion resistance, crucial for applications demanding high aesthetic quality and durability. However, this same film necessitates careful handling during processing. Scratches and blemishes are readily visible, impacting the final product's value. Our experience shows that maintaining meticulous cleanliness in the unwinding, slitting, and subsequent processes is paramount. Improper tension control during these stages can also lead to film damage, so precise machine calibration and regular maintenance are critical to avoid costly rework or scrap.

Furthermore, the specific H14 temper of the 1050 alloy itself contributes to the coil's unique properties. While it offers good formability, the blue film reduces its overall ductility, making it more prone to cracking during deep drawing or bending operations. We've found that optimizing tooling geometry and lubrication strategies is essential to mitigate these risks. We've also experimented with pre-heating the coil to improve formability without compromising film integrity, yielding improved yield rates. the interplay between the alloy's mechanical properties and the characteristics of the blue film coating is to successful processing and maximizing the value of this specialized material.

Chemical Composition (% by weight)

| Element | Minimum | Maximum |

|---|---|---|

| Al | Balance | - |

| Fe | - | 0.40 |

| Si | - | 0.25 |

| Cu | - | 0.05 |

| Mn | - | 0.05 |

| Mg | - | 0.05 |

| Cr | - | 0.05 |

| Zn | - | 0.05 |

| Ti | - | 0.03 |

The near-pure aluminum composition underpins the material’s excellent electrical and thermal conductivity as well as unsurpassed corrosion resistance.

The Tempering: What Does H14 Mean?

The H14 temper signifies the following:

- Partial hardening through strain hardening (work hardening),

- The material has been cold worked to approximately 50% of its ultimate tensile strength,

- It exhibits moderate strength and excellent ductility.

Typical Mechanical Properties in H14 Temper

| Property | Value | Standard Reference |

|---|---|---|

| Tensile Strength (MPa) | 90 - 110 | GB/T 3190-2008 / ASTM |

| Yield Strength (MPa) | 70 - 90 | |

| Elongation (%) | ~1 - 3 (due to strain hardening) | |

| Hardness (HB) | ~30-40 |

This balance makes 1050-H14 a choice alloy when surface finishing and dimensional accuracy are paramount.

The Blue Film Cladding Explained

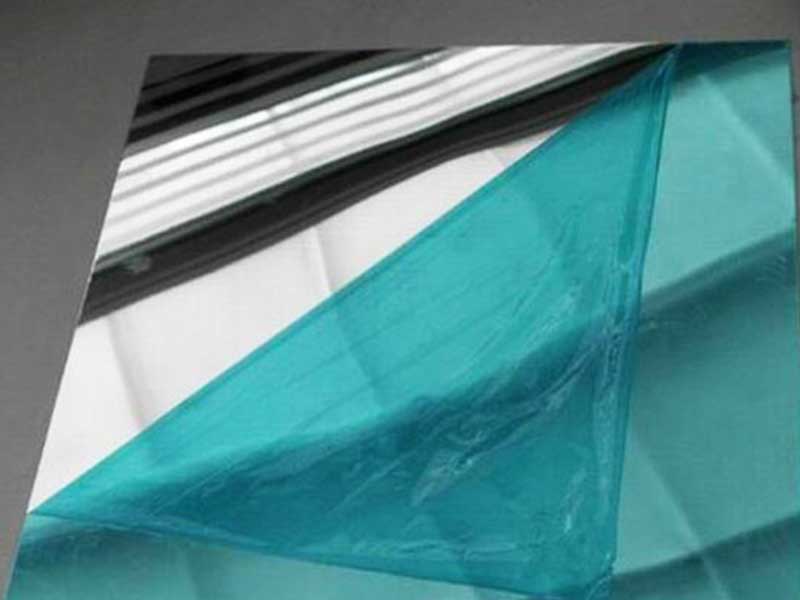

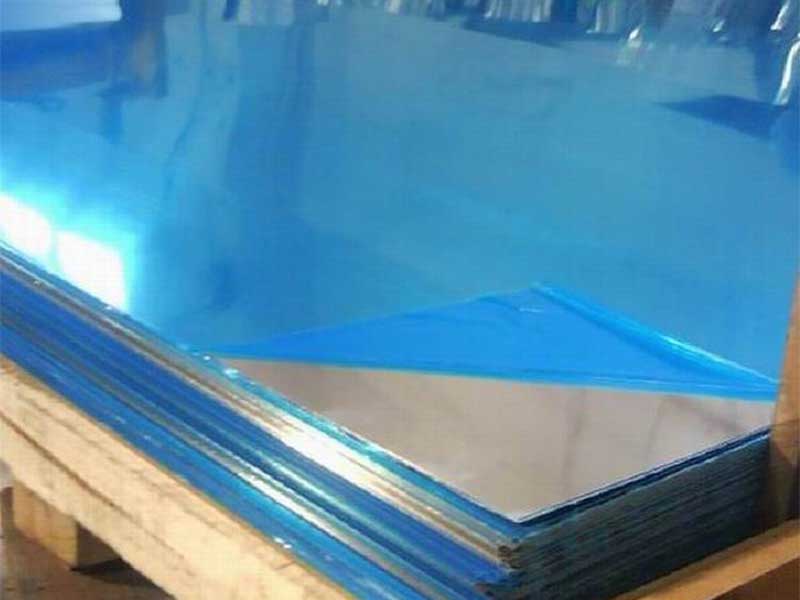

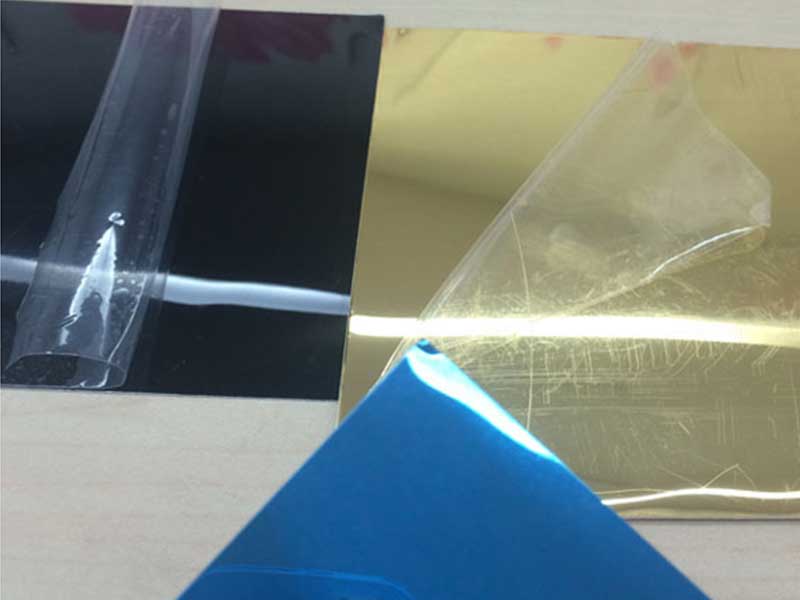

Before the aluminum coil undergoes subsequent processing, such as fabrication or assembly, it is often clad with a blue protective film — a plastic film layer applied to the aluminum mirror surface.

Why Use Blue Film Cladding?

- Surface Protection: Guards the delicate mirror finish from scratches, dirt, and oxidation during transit and handling.

- Ease of Identification: Visually aids cluster sorting and surface checking during production.

- Customer Benefit: After processing, peeling off the film reveals a pristine mirror surface, vital in decorative or optical applications.

Mirror Finish: More Than Just Appearance

The mirror treatment goes beyond mere aesthetics. Achieving a genuinely reflective aluminum surface requires:

- Precision cold rolling, to reduce surface imperfections.

- Polishing and buffing, often through mechanical and chemical means.

- Consistent quality checks to monitor reflectivity, roughness, and flatness.

The finished product typically reaches a surface roughness (Ra) of less than 0.1 µm, delivering superior reflectance and making it suitable for applications requiring optical clarity.

Application Areas

- Architectural Décor: Use in building façades and interiors where reflective qualities enhance lighting and aesthetics.

- Lighting Fixtures: Leveraged for reflectors and diffusers in LED and traditional lighting solutions.

- Advertising Panels: High reflectivity ensures vibrant and eye-catching displays.

- Kitchen Appliances and Utensils: Naturally corrosion-resistant, light, and stylish finish.

- Solar Energy Equipment: Reflective surfaces maximize sunlight gathering efficiency.

Implementation Standards and Inspection

When procuring or applying 1050-H14 blue film cladding mirror aluminum coils, clients and manufacturers typically rely on the following:

- Standards: GB/T 3190 (Chemical composition), ASTM B209 (Aluminum Sheet and Plate), JIS H4000 (Aluminum and aluminum alloys).

- Inspection Methods: Surface brightness measurement using gloss meters, chemical analysis by spectroscopy, and mechanical tests via universal testing machines.

- Processing Precautions: Ensuring minimal micro-scratches post-handling; controlled humidity and temperature to avoid adhesive problems with the film.

Final Thoughts: A Balanced Aluminum Choice

The beauty of the 1050-H14 blue film cladding mirror aluminum coil lies in its balanced offering of pure metal corrosion resistance, moderate strength, precision finishing, and protection ease. For product engineers, architects, and assemblers, it represents the backbone support layer — often unseen, but critical — in crafting products where durability and appearance harmonize.

This specialized aluminum alloy and finish cleverly combine nature’s inherent advantages with modern processing ingenuity, providing a shining example of how materials evolve to meet precise practical demands.

If you are considering aluminum solutions that require a mirrored appearance alongside protection and medium tensile strength, the 1050-H14 blue film cladding mirror aluminum coil invites a closer look. Your products may shine literally and figuratively as a result.

https://www.al-alloy.com/a/1050-h14-blue-film-cladding-mirror-aluminum-coil.html