Anodized aluminum sheet 1050 1060 1070 3003 Ho H14

Anodized aluminum sheet is often described as a finish, a surface treatment chosen for color or corrosion resistance. That view is useful, but incomplete. A more revealing perspective is to treat anodizing as a "manufactured interface" that converts a common sheet alloy into a controlled, engineered skin: harder than the base metal, chemically stable, and optically tunable. When you look at anodized aluminum sheet in grades 1050, 1060, 1070, and 3003-especially in tempers noted as O (often written "Ho" in some markets) and H14-you're really selecting a combined system: base alloy purity and work-hardening level, plus an oxide architecture whose thickness and sealing define durability, appearance, and downstream fabrication behavior.

What anodizing really adds: an oxide architecture, not paint

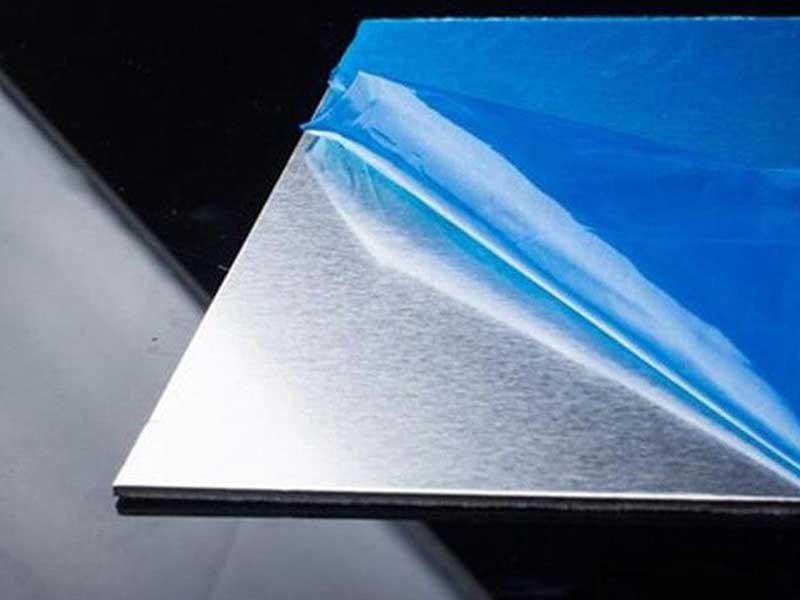

Anodizing grows aluminum oxide from the metal itself. Unlike coatings that sit on top, the anodic film is partially penetrative: a portion of the oxide grows inward and a portion outward. The resulting structure is typically a thin barrier layer with a porous layer above it. Those pores are why anodizing can be dyed and why sealing matters; sealing hydrates the oxide and closes pores, improving corrosion resistance and stain resistance.

Alloy selection through the lens of anodizing

Choosing among 1050, 1060, 1070, and 3003 becomes clearer when you start with the intended surface and forming route rather than only tensile properties.

1050, 1060, 1070 are commercially pure aluminum series. Their core advantages for anodized sheet include excellent formability, high thermal and electrical conductivity, and the ability to achieve high-brightness finishes after proper mechanical or chemical brightening. Where the part is thin, wide, and appearance-driven-reflective panels, nameplates, lamp housings, curtain wall trims-these alloys deliver stable anodic cosmetics and consistent dye uptake.

3003 is an Al-Mn alloy, selected when you need better strength and dent resistance while maintaining decent formability. For anodized products that will be handled, installed, or lightly impacted, 3003 in H14 often gives a practical edge. It is common in general sheet metal work, building components, transportation interiors, and appliance housings where a tougher sheet reduces waviness and "oil canning."

Temper as a hidden design lever: O (Ho) vs H14

Temper is where the conversation becomes truly technical, because anodizing amplifies what the sheet already "remembers" from rolling, annealing, and handling.

O temper (sometimes written "Ho" in ordering language) indicates annealed, soft condition. It is chosen when deep drawing, complex forming, or tight radii are required. For anodizing, O temper can be advantageous because it reduces forming-induced surface strain patterns. However, very soft sheet is more prone to handling damage before anodizing; scratches and pressure marks become permanently recorded under the oxide.

H14 is a strain-hardened temper, roughly half-hard. It increases strength and improves flatness stability for large panels. That stability is valuable in anodized architectural sheets because the anodic film reflects light and makes waviness more visible. The trade-off is that aggressive forming on H14 can show "strain lines" or micro-texture differences after anodizing, especially on high-purity 1xxx alloys where the surface is otherwise very uniform. If the part requires only gentle bends, hems, or roll forming, H14 is often a strong choice.

Practical anodizing parameters and implementation standards

In production, the anodized performance depends on film thickness, sealing quality, and pretreatment consistency. Requirements vary by application, but common industrial practice aligns with widely used standards such as ISO 7599 for decorative and protective anodizing, and (where specified) AA/DIN equivalents. For architectural work, many buyers also align performance targets with AAMA guidance (often referenced for anodized aluminum in building products), even when the anodize line is certified to ISO.

Typical technical ranges used for anodized sheet include:

- Film thickness for indoor decorative use: around 5–10 μm, often with dye and sealing

- Film thickness for general exterior exposure: around 10–20 μm (or higher depending on specification)

- Hard anodizing (when required for wear resistance): thicker films are possible, but sheet appearance and formability requirements often push designers back toward conventional anodize thickness

Sealing choices matter. Hot deionized water sealing and nickel acetate sealing are common routes to improve corrosion resistance and reduce dye bleed. If fingerprint resistance is critical, designers sometimes specify post-seal topcoats or integrated pretreatment chemistries, but those should be evaluated for adhesion and color shift over time.

Chemical composition (typical limits)

Below is a practical reference table for the alloys discussed. Exact limits vary slightly by standard and supplier; always confirm against the governing specification for your project.

| Alloy | Al (min, %) | Si (max, %) | Fe (max, %) | Cu (max, %) | Mn (%) | Mg (max, %) | Zn (max, %) | Ti (max, %) |

|---|---|---|---|---|---|---|---|---|

| 1050 | 99.50 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.07 | 0.05 |

| 1060 | 99.60 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 |

| 1070 | 99.70 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | 0.04 | 0.03 |

| 3003 | balance | 0.60 | 0.70 | 0.05–0.20 | 1.0–1.5 | 0.05 | 0.10 | 0.10 |

The anodizing implication is this: as purity increases (moving toward 1070), the oxide tends to look cleaner and brighter; as alloying increases (3003), mechanical robustness improves but color tone and uniformity can shift, especially across lots if surface finishing is not tightly controlled.

Features that matter in real applications

Corrosion resistance is the headline benefit, but anodizing's most valuable feature is predictability. A sealed anodic film resists oxidation staining, supports stable color, and protects against mild urban or indoor environments. For signage and decorative panels, the ability to dye pores gives controlled aesthetics without sacrificing metallic texture.

Wear resistance is another quiet advantage. Even a conventional anodize film is much harder than aluminum. In sliding contact areas it won't behave like hard anodize on 6xxx parts, but it significantly improves scuff resistance for panels, trims, and frequently touched surfaces.

Thermal behavior can be decisive. Anodized 1xxx sheet is used in lighting and heat-related assemblies because the base alloy conducts heat efficiently while the anodic film provides electrical insulation and controlled emissivity. That makes 1050/1060/1070 attractive for reflector components, LED housings, and thermal spreader-adjacent panels where you want a metallic look plus functional surface stability.

Formability and cosmetic stability define manufacturing yield. For deep-drawn parts, O temper 1050/1060 is often the low-risk path; for large flat sheets and lightly formed architectural parts, H14 in 3003 or 1050 balances stiffness with workable bends. When appearance is critical, specifying a consistent pretreatment sequence-degrease, etch or bright dip, desmut, anodize, seal-often matters more than chasing the last increment of alloy purity.

Application snapshots: choosing with intent

For interior decorative sheets, appliance faces, nameplates, and lighting reflectors, 1050/1060/1070 in O or light H tempers excel because they anodize with high clarity and accept brightening processes well. When the part will be handled heavily or needs dent resistance in service-interior panels, cladding details, transportation interiors-3003 H14 often improves durability and flatness, with anodizing providing the protective and aesthetic finish.

From this viewpoint, "anodized aluminum sheet 1050 1060 1070 3003 Ho H14" is not a shopping list of grades. It's a toolkit for engineering a surface that behaves like a material of its own. The best results come when alloy purity, temper, pretreatment, anodize thickness, and sealing are selected as one integrated design-because anodizing doesn't hide the metal underneath; it reveals it, then protects it.

https://www.al-alloy.com/a/anodized-aluminum-sheet-1050-1060-1070-3003-ho-h14.html