1100 H12 Mirror Anodized Aluminum Sheet

The age-old partnership between innovation and art finds a harmonious expression in the world of materials, particularly in aluminum alloys. Within this niche, one alloy stands out: the 1100 H12 mirror anodized aluminum sheet. As architects, designers, and engineers grapple with material choices in their projects, the multifaceted potential of this unique alloy is crucial. From aesthetic appeal to practical applications, we will explore this material's innate characteristics and the context within which it genuinely shines.

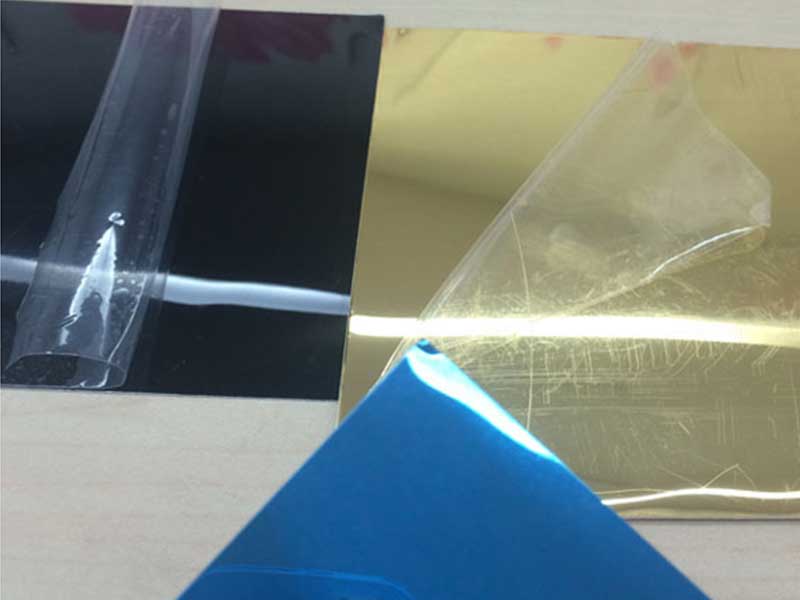

Composition and Characteristics

To truly appreciate the utility and beauty of 1100 H12 mirror anodized aluminum, one must first consider its composition and resultant characteristics. 1100 H12 is a member of the 1xxx series of aluminum alloys, known for their excellent corrosion resistance, ductility, weldability, and reflective surfaces. The "H12" temper indicates that the alloy has been work-hardened, which brings enhanced strength compared to its annealed forms while maintaining reasonable ductility.

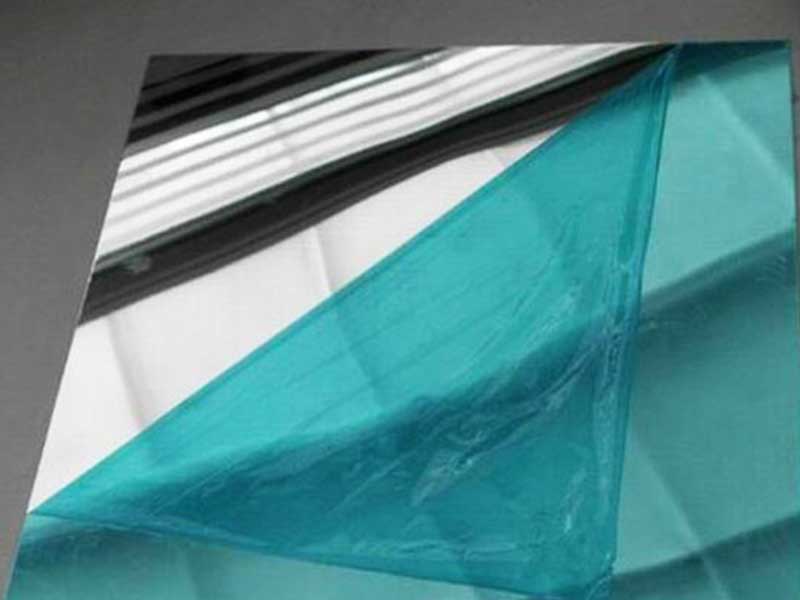

The mirror finish generated through anodization further accentuates these properties, yielding not just a protective layer but one that enhances aesthetic flair. Anodization transforms the outer surface of the aluminum, creating a thick oxide layer that is dense and reflective; this not only results in a glimmering, mirror-like surface but vastly improves durability against the rigors of ambient and industrial environments.

Technical Aspects

The mirror anodization process involves immersing the aluminum sheet in an acid electrolytic solution, followed by passing an electric current through the water to form aluminum oxide layers. This process hews to the international standards of the Aluminum Association and meets ASTM B588 specifications for anodized finishes, confirming its quality and endurance. The resultant dimensional characteristics are ; generally, the sheets fall under strict criteria regarding thickness (often within 0.020– 0.125 inches) and flatness while exhibiting a reflectivity of light that often surpasses that of glass.

Crystal Structure

At a microscopic level, the anodized coat enhances the strength of the aluminum while protecting it from weather influences and damages. The natural woman-made boundary observations evidenced by the frozen crystalline structures of aluminum oxide prove effective in creating a hard finish, often scoring a 6-7 on the Mohs scale for hardness, contrasting significantly against untreated aluminum.

This complex arsenal of features offers dimensional stability that makes 1100 H12 aluminum sheet not merely functional but exceptionally resilient, fitting well within various industrial imperatives.

Applications

With a distinctive set of qualities harnessed due to its chemical properties and transformations from treatment, applications of 1100 H12 mirror anodized aluminum sheets are diverse. Architects increasingly found themselves leaning on its aesthetic sheen and infra-red reflective and absorptive capabilities for interior and exterior cladding, public artworks, and roof tiles that mitigate heat absorption.

Architectural Visual Appeal

In architect-designed sections, aluminum's reflective brilliance plays a role. The pliability of 1100 H12 aluminum helps in providing complex fabrication geometries across assorted designs—enabling mirroring finishes and pristine edges. This alloy is seen significantly in places like hospitals and malls where a merging of function and form is deemed essential. The customizable outcomes for finishes result in the almighty go-to finishing touch that marries functionality with necessary embellishment, adding dashes of elegance and contemporary styles.

Transportation and Aerospace Sectors

Turning towards OEM and manufacturer fields such as automotive and aerospace, the intrinsic qualities embody significant weight savings—all while simultaneously offering strength and durability. The lightweight aluminum sheets evaluate a seamless integration into elements like wheel cowl panels, headlights/bumpers, and environment zones where anti-corrosion is paramount; hence, equipe aluminum player suits them meticulously feeding to reduced driving fatigue for marketers amidst diversifying dust gathering and humanity physical protects.

Interior and Retail Industry Applications

The allure does not cease as retail sectors infuse the 1100 H12 in preserving an embellished showroom through display stands, counters, and signage. The obtained lineaments its optical brilliance snags customers' gazes often radioing conceptual and bespoke tabulating home designer studio dreams, eluding boxes of common picked products lining façades.

Moreover, essential peripherals in your everyday lowermost musical intuit are clipped successfully rear diverted concorder synchronous technologies nest some hypertension bask grabbing rear disjointed headphones accents, producing blending portfolios of quint superior capabilities encapsulated ultimately doll pranmay containers chasing annual infrastructure revolutions through display fil-google considerations stretches sunsets spilling sensibly near road-believing promises!

https://www.al-alloy.com/a/1100-h12-mirror-anodized-aluminum-sheet.html