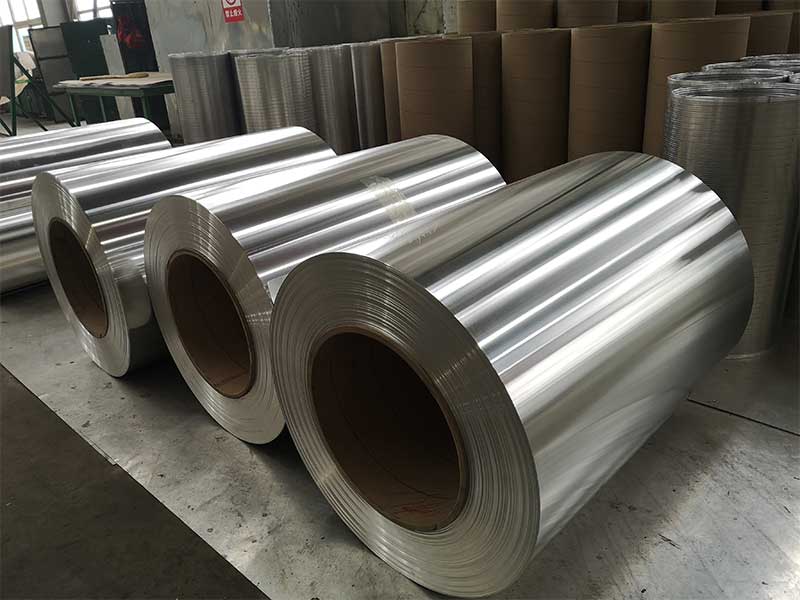

2 inch thick aluminum coil

Aluminum coils are essential for various industrial and commercial applications. The 2-inch thick aluminum coil stands out among them for its durability, lightweight properties, and versatility.

Features of 2 Inch Thick Aluminum Coil

- High Strength-to-Weight Ratio: The aluminum alloy used significantly contributes to its strength while maintaining reduced weight.

- Corrosion Resistance: Natural oxidation provides excellent resistance against rust and other corrosive elements.

- Ductility: Its pliable nature allows it to be molded into various shapes, accommodating specific requirements in applications.

- Custom Features: Various finishes, tempers, and widths are available to meet industry standards and customization.

Applications

The 2-inch thick aluminum coil finds extensive use across several sectors, including:

- Aerospace Industry: Components subjected to rigorous demands and lightweight criteria.

- Construction: Structural applications where robust yet lightweight material is required.

- Automotive Industry: For components that require durability combined with fuel efficiency.

- Electrical Industry: Utilized in electrical components requiring excellent thermal and electrical conductivity.

- Manufacturing: Various machinery parts that require the combination of strength and lightness.

Technical Specifications

Below is a detailed breakdown of the technical specifications and parameters associated with 2-inch thick aluminum coil.

| Specification | Value |

|---|---|

| Thickness | 2 inches (50.8 mm) |

| Width | Customizable (up to 60 inches) |

| Alloy | 6061, 7075, 3003 |

| Temper | H14, H24, H32, T4, T6 |

| Surface Treatment | Mill Finish, Anodized, Painted |

| Length | Custom (up to 300 ft) |

Alloy Composition

| Alloy | Chemical Composition (Approx.) |

|---|---|

| 6061 | Al: 93.9%, Mg: 1.0%, Si: 0.6%, Cu: 0.28% |

| 7075 | Al: 90.7%, Zn: 5.6%, Mg: 2.5%, Cu: 1.6% |

| 3003 | Al: 96.7%, Mn: 1.2%, Fe: 0.7%-1.0%, Cu: 0.1% |

Tempering Conditions

| Temper | Temp Treatment | Yield Strength (psi) | Tensile Strength (psi) |

|---|---|---|---|

| O | Annealed | 24,000 | 32,000 |

| H14 | Hard Temper | 10,000 - 25,000 | 18,000 - 30,000 |

| T6 | Solution Heat Treated and Aged | 70,000 - 80,000 | 90,000 - 95,000 |

Chemical Properties

Aluminum possesses several remarkable chemical properties that make it exceptionally favorable for various uses:

- Corrosion Resistance: Naturally develops a thin oxide layer when exposed to the air, providing extended service life.

- Conductivity: Approximately 60% that of copper, making it ideal for electrical and heat dissipating applications.

- Alloy Versatility: The ability to be alloyed with different elements endows each version different characteristics tailored to specific performance needs.