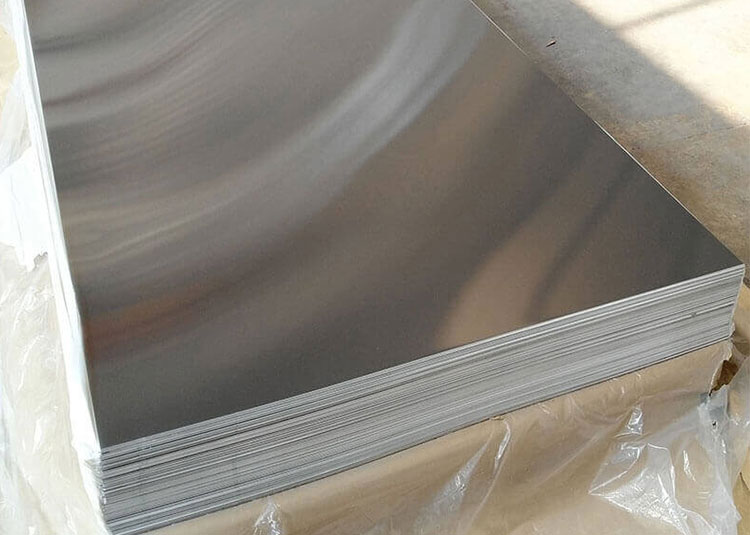

2024 t851 aluminum plate

The 2024 T851 aluminum plate is a high-strength aluminum alloy offering outstanding mechanical properties and exceptional performance characteristics. With its resilience and corrosion resistance, this aluminum plate is commonly used in aerospace and other demanding applications, making it a popular choice for engineers and manufacturers alike.

Features

- High Strength: 2024 aluminum plate is recognized for its excellent strength-to-weight ratio, making it an ideal choice for structural applications.

- Temperature Resistance: High thermal stability provides resilience in extreme temperatures, preserving integrity and performance under various conditions.

- Machinability: This aluminum plate offers good machinability, allowing for easy shaping and fabrication.

- Corrosion Resistance: Treatment methods enhance its natural resistance against corrosion, suitable for tough environments.

Applications

Due to its robust properties, 2024 T851 aluminum plate is widely used in industries such as:

- Aerospace: Aircraft structures, wing skins, and other critical frames.

- Automotive: Structural components in high-performance vehicles.

- Military: Applications for armored vehicles and military transport aircraft.

- Manufacturing and tooling: Precision tools and fixtures due to being easily machined.

Technical Specifications

The following table summarizes the technical specifications for the 2024 T851 aluminum plate:

| Property | Value |

|---|---|

| Alloy | 2024 |

| Temper | T851 |

| Standard | ASTM B 209, AMS J464 |

| Thickness Range | 0.250" - 6.000" |

| Width | Up to 60" |

| Length | Standard lengths up to 20' |

| Density | 0.0975 lb/in³ (2700 kg/m³) |

Chemical Composition

The following table illustrates the chemical properties of 2024 aluminum alloy:

| Element | Percentage (%) |

|---|---|

| Aluminum | 90.7 to 95.7 |

| Copper | 3.8 to 4.9 |

| Manganese | 0.3 to 0.9 |

| Silicon | 0.5 max |

| Magnesium | 0.3 max |

| Zinc | 0.25 max |

| Iron | 0.5 max |

| Other Elements | 0.15 each, 0.5 total max |

Alloy Tempering Conditions

The T851 temper frame involves the following processes:

- Solution Heat Treatment: Heated to a specific temperature, followed by rapid quenching to stabilize the microstructure.

- Artificial Aging: Followed by controlled aging at elevated temperatures to enhance hardness and strength properties.

- Fatigue Resistance: Aligns with optimal mechanical properties characterized for high tasks.