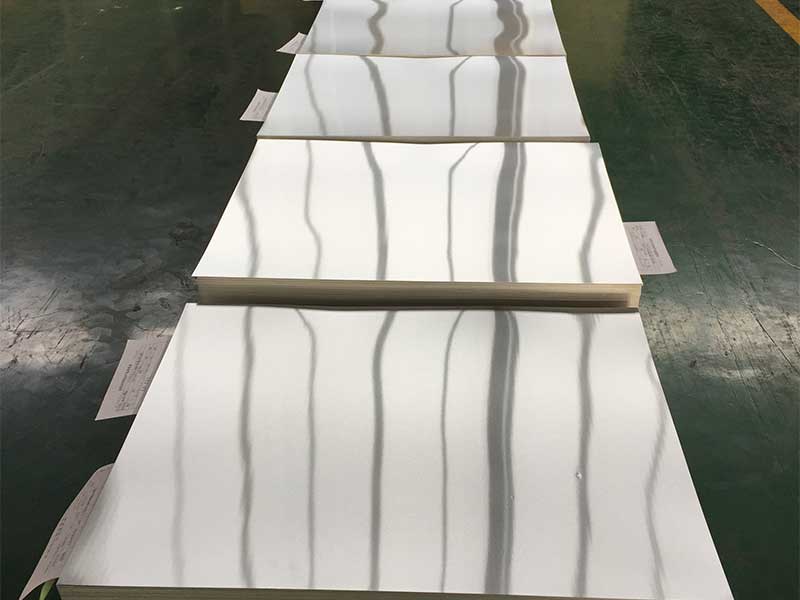

25mm thick aluminium plate

When we think of heavy-duty materials, the first ones that often come to mind are steel or reinforced concrete. However, lurking in the shadows, ready to steal the limelight and conquer various applications, is the unsung hero: 25mm thick aluminum plates. Yes, you read that right—aluminum! This versatile material brings a surprisingly wide range of benefits to the table, and today we’ll dive into its functions and applications from a fresh perspective.

Lightweight Yet Sturdy

Let’s start with the basics. One of aluminum’s crowning glories is its lightweight nature. An aluminum plate with a thickness of 25mm might seem hefty at first glance, but when compared to steel— which can weigh almost three times as much—the advantage of aluminum becomes clear. This balancer acts as an alligator in the water—powerful yet graceful, capable of sending ripples across various industries without weighing operations down (pun intended!).

The lightness of this aluminum plate makes it ridiculously convenient for transport and handling on jobsites—whether you’re assembling tower structures or working on wooded caravans. Moving and maneuvering large sheets becomes a breeze with aluminum, so if you’re handling significant components, you’ll thank the thickness along with (of course) the material itself.

A Champion Against Corrosion

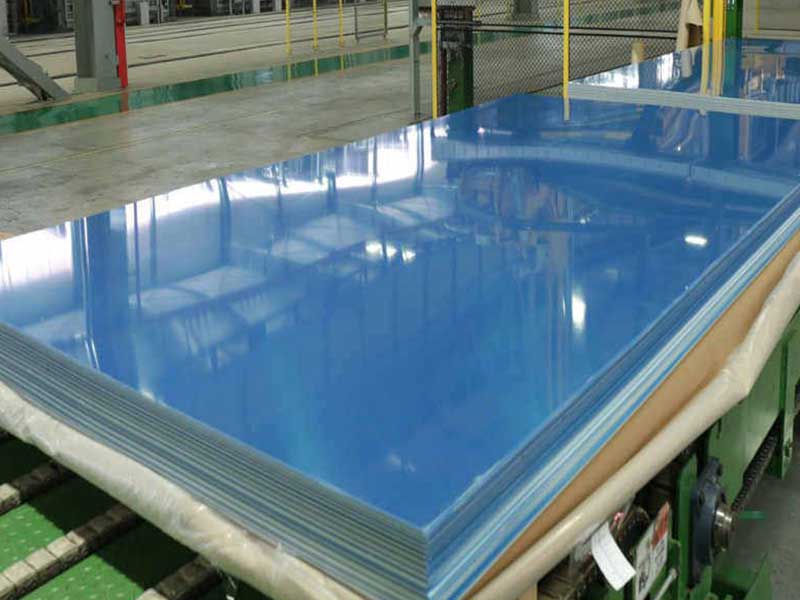

Now, let's pivot to the unwelcoming, yet relentlessly persistent force of nature: corrosion. Whether it's battling the salty air by the oceanfront or the occasional drizzle in a manufacturing facility, 25mm thick aluminum plates are here to uphold the fight. Thanks to aluminum’s inherent resistance to corrosion, this material requires less maintenance and fewer coating treatments compared to other metals.

Let’s face it—anything that reduces downtime is a friend in business (or life!). Consider the automotive industry, for instance. These plates can be fashioned into parts that therapeutic treatments can’t defeat. Less worry, more time on the road—talk about a win-win situation.

Thermal Conductivity That Works Wonders

Aluminum plates, particularly 25mm thick pieces, have remarkable thermal conductivity. If you've ever tried to fry an egg on a cold stovetop, you know the importance of heat distribution! In the world of manufacturing, this characteristic seamlessly transitions into efficient machining processes and heat dissipation applications.

In tools or even aviation components where overheating could spell disaster, having a strong and thermally conductive plate can ensure optimal working temperatures. This translates into consistent performance for vital operations. You can think of it as an athlete who has perfected their warm-up routine before hitting the arena—both ready to perform seamlessly under pressure.

Intricate Industrial Applications

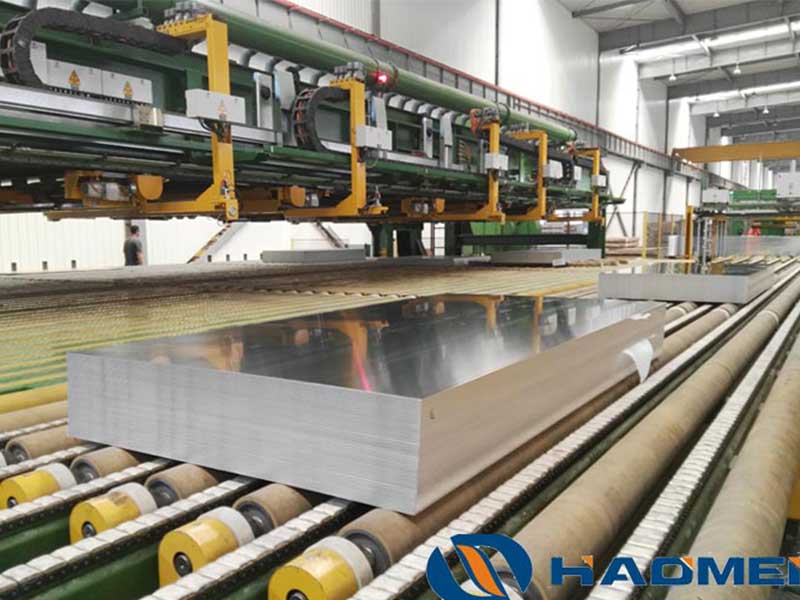

So now let's discuss applications—where the magic unfolds. The weight, corrosion resistance, and thermal conductivity of a 25mm thick aluminum plate translate into a myriad of fascinating applications across industries.

Aerospace: In the aviation world, aluminum is revered for its strength-to-weight ratio and is often a primary choice for wing and fuselage components. The fact that it's not a heavyweight champion enhances fuel efficiency without sacrificing performance.

Automotive Manufacturing: Think about all those intricate engine components that need to withstand heat while remaining light enough to enhance car performance. You guessed it: those components could be built from a shiny block of that modest 25mm aluminum plate.

Marine Industry: South-facing boat manufacturers appreciate the aluminum plate's resistance to saltwater corrosion. It translates to long-lasting decking, hulls, and other structural components that stand the test of time and climatic afflictions.

Construction: Whether it's for arching beams or expansive flooring in industrial applications, 25mm thick aluminum plates provides unmatched strength combined with a lightweight profile. Architects are often excited to explore its potential symbols for modern-day aesthetics.

Signage and Displays: Design-savvy entrepreneurs love using aluminum plates for display frameworks, banners, or signboards. With a little anodizing or powder coating, they look fabulous and provide form without forgoing function.

Closing Thoughts

Aluminum plates are quietly making their mark on the world—in a metallic dance of robustness and adaptability. When it comes to the 25mm thick variant, the combination of lightweight construction, superior corrosion resistance, and thermal abilities offers dandy solutions to modern-day engineering challenges across multiple fields. The uniqueness of aluminum allows it to shine in scenarios you might not initially expect, all while sporting that hot shot’s aesthetic.

As we’ve explored in this piece, don’t underestimate the generosity of good old aluminum plates. Whether it’s aerial microcosms far above us or the submerged depths of the sea, these plates will always find a way to hold their ground. And who knows? Adopting this overlooked material in your next project could just be the game-changer you didn’t see coming!