4 x 8 aluminum aluminium plate

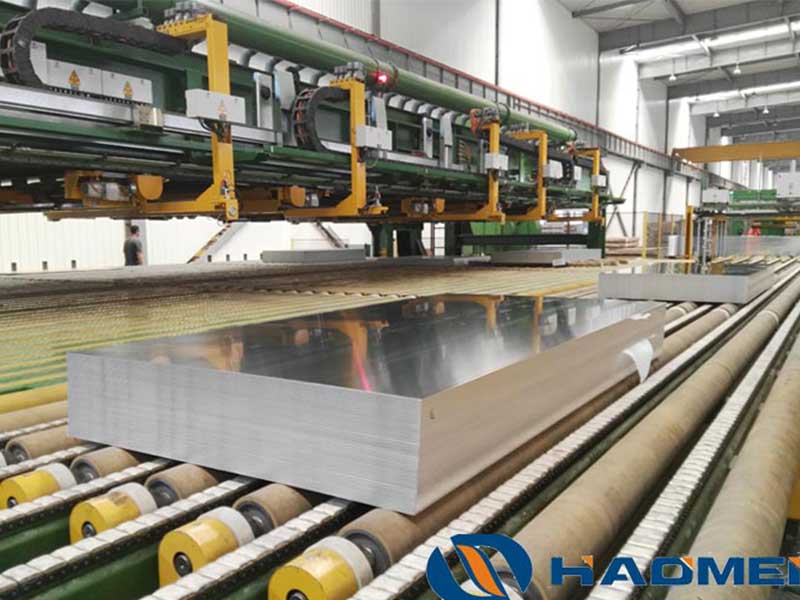

The 4 x 8 aluminum plate stands as a versatile and essential product in the metal industry, renowned for its balance of strength, lightweight features, and corrosion resistance. This standard-size aluminum sheet, typically measuring four feet by eight feet, serves as a fundamental building block for various industrial and commercial applications. But what makes the 4 x 8 aluminum plate uniquely functional, and how does its technical makeup optimize usability across sectors?

Technical Overview: What Defines the 4 x 8 Aluminum Plate?

At its core, the 4 x 8 aluminum plate is crafted with high-grade aluminum alloys, like 6061, 5052, or 7075, each offering unique mechanical properties:

- Alloy Specification: For instance, 6061 offers an excellent blend of strength, corrosion resistance, and machinability. Meanwhile, 7075 aluminum provides top-tier strength, ideal for structural applications.

- Thickness Variability: Thickness options commonly range from 1/8 inch (3.175 mm) to over 1 inch (25.4 mm), affecting rigidity and weight. This range enables the 4 x 8 aluminum plate to be usable in everything from lightweight paneling to heavy machinery bases.

- Sheet Size Advantages: The uniform 4 x 8 foot dimension simplifies cutting, fabrication, and transportation, aligning perfectly with industry-standard equipment and minimizing factory downtime.

- Surface Treatments and Finishes: Options include anodizing, powder coating, and mill finish. These enhance durability, resist oxidation, and improve appearance or paint adhesion depending on the application.

Functions and Functional Benefits

The 4 x 8 aluminum plate’s versatility stems from several intrinsic functional properties:

- Lightweight Strength: Aluminum plates provide outstanding tensile strength relative to their weight. This feature significantly reduces overall energy consumption in transportation or structural support usage, while maintaining integrity.

- Corrosion & Weather Resistance: Naturally resistant to oxidation and ideal for outdoor use, aluminum prevents rust, making it dependable for marine, architectural, and automotive sectors.

- Thermal and Electrical Conductivity: Although aluminum doesn’t match copper for electrical conductivity, it offers sufficiently high conductivity combined with weight advantages, diving it ideal for heat sinks, enclosures, and electronic casings.

- Ease of Fabrication: The 4 x 8 format adapts seamlessly to cutting, welding, bending, and forming. This mutable nature shortens production cycles and improves end-product versatility.

Applications across Industries

Thanks to its balance of size, strength, and adaptability, the 4 x 8 aluminum plate finds widespread applications:

- Aerospace Industry: Precision-machined 4 x 8 aluminum plates are critical for fuselage panels, wing structures, and internal components requiring lightweight yet robust construction.

- Transportation: Used in manufacturing truck bodies, rail car panels, and ship hulls, facilitating durability without compromising fuel efficiency.

- Construction and Architecture: Ideal for curtain walls, roofing sheets, and frameworks, especially when corrosion resistance and aesthetic finishes matter.

- Manufacturing and Fabrication: The plate serves as base material for pressure vessels, machinery parts, and industrial equipment enclosures.

- Signage and Display: Its smooth surface and resistance to environmental exposure make the 4 x 8 aluminum plate excellent for billboards, direction signs, and light-reflective display backgrounds.

https://www.al-alloy.com/a/4-x-8-aluminum-aluminium-plate.html