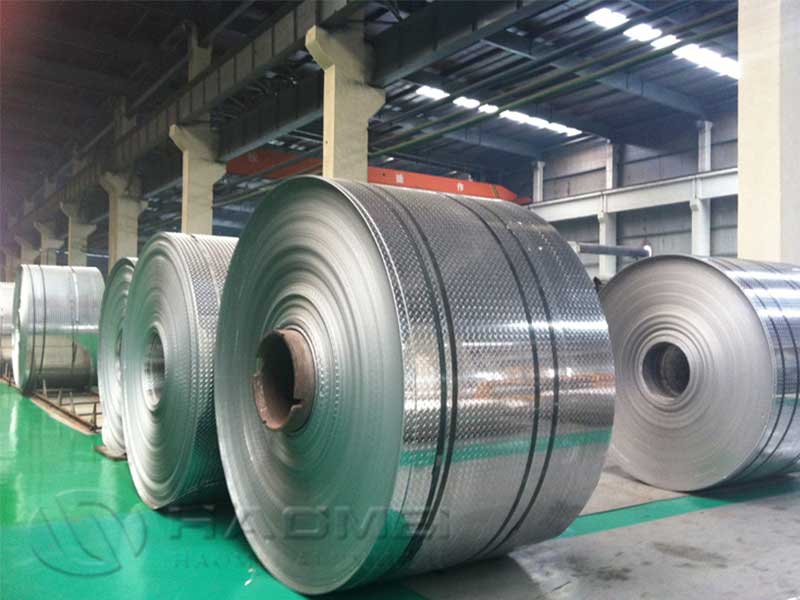

5052 aluminum checkered plate and aluminum sheet

When it comes to industrial applications requiring remarkable strength, corrosion resistance, and aesthetic appeal, 5052 aluminum checkered plate and aluminum sheet is know as premium materials of choice. While many know these products just as structural surfaces or protective coatings, their technical properties, production standards, and versatile functions opens up possibilities for smarter selection and better performance across industries.

What is 5052 Aluminum Checkered Plate and Sheet?

5052 aluminum belongs to the 5xxx series aluminum alloys, characterized primarily by magnesium as the alloying element. Known for exceptional anti-corrosive qualities, 5052 alloy is often manufactured into two common forms:

- Aluminum Sheet: Thin, flat, and can be customized in thicknesses, used in various fabrication processes.

- Checkered Plate (Tread Plate): The same alloy pressed or rolled with raised diamond-shaped patterns (also called tread patterns) for increased slip resistance and styling.

These two variants play complementary roles, with the sheet offering versatility in shaping and assembly, and the checkered plate combining functionality with rugged durability on exposed surfaces.

Technical Parameters and Standards

the benchmarks and production parameters for 5052 aluminum sheet and checkered plate enables users to match materials precisely to application requirements.

| Parameter | Specification |

|---|---|

| Alloy: | 5052 |

| Chemical Composition: | |

| - Aluminum (Al) | Balance (~97.52% min) |

| - Magnesium (Mg) | 2.2 - 2.8 % |

| - Chromium (Cr) | 0.15 - 0.35 % |

| - Manganese (Mn) | ≤ 0.10 % |

| - Copper (Cu) | ≤ 0.10 % |

| - Iron (Fe) | ≤ 0.40 % |

| - Silicon (Si) | ≤ 0.25 % |

| Property | Value | Notes |

|---|---|---|

| Thickness Range | 0.2 mm – 8 mm (Sheet) | Varies with supplier and intended use |

| Thickness Range Checkered Plate | 1.5 mm – 10 mm | Usually thicker for durability |

| Temper Condition | H32 (strain-hardened and stabilized) standard; also H34, H36 | Provides moderate strength and excellent formability |

| Tensile Strength | 215-275 MPa | Depending on temper |

| Yield Strength | 130-205 MPa | Depending on temper and thickness |

| Elongation | 7-12 % | Indicates flexibility before breaking |

| Corrosion Resistance | Excellent | Especially in marine, industrial atmospheres |

Implementation Standards:

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- EN 485: Metallic materials - Measurement of thickness

- JIS H4000: Japanese Industrial Standard for Aluminum Alloy Sheets

- Checkered plates manufacture stresses consistency with ASTM B209 and machinery usage specifications within MIL-A-8625 anodizing processes.

Functionality: Why Choose 5052 Alloy?

Superior Corrosion Resistance:The presence of about 2.5% magnesium enriches the alloy’s oxide layer protecting it strongly from saline environments, making it ideal for marine vessels, fuel tanks, and chemical plant interiors.

Excellent Formability and Weldability:The standard temper H32 provides moderate work hardening while keeping enough ductility for forming. This means large sheets can be bent, shaped, or welded without fear of losing structural integrity. This functional elasticity widens the variety of potential fabrications including roofing panels, signboards, and heat exchangers.

Slip Resistance and Strength in Checkered Plate:The embossed tread design in checkered plate prevents slip-related accidents, an important safety feature for walkways, staircases, and emergency vehicle platforms. The raised ridges add structural reinforcement against impact as well.

Applications Run the Spectrum

- Transportation Industry: Flooring and side panels in trucks and trailers; bus flooring using lightweight checkered sheets enhance durability without excess weight.

- Marine and Offshore: Boat decks, pontoons, oil rigs flooring where exposure to sea and chemical agents demand durable corrosion resistance.

- Architectural and Interior: Interior wall paneling for improved aesthetics and ease of maintenance; slip resistance for commercial kitchens and public spaces.

- Industrial Equipment: Protective shields on machinery, radiant heating elements supports, tool compartments.

- Energy Sector: Covers for electrical panels, transformer enclosures needing spark resistance certified by careful temper control.

Alloy Tempering and Resistance Insights

The temper designation for 5052 aluminum, commonly H32, reflects processing steps involving strain-hardening and stabilization via heat treatments — which serve to optimize strength and machinability:

- H32 Temper: Increased yield and tensile strength without crushing formability.

- Other tempers like O (annealed) provide maximal ductility but less strength.

- For truckbeds or elevated anti-slip requirements, the combination of hardened 5052 Tread Plate assures long service life under heavy impact and abrasive usage.

Besides mechanical properties, the corrosion resistance stands the test with an experiment-proven film continuity that resists pitting even at high chloride concentrations, outperforming typical 6061 and 3003 equivalents in stand-in marine environments.

Chemical and Physical Data Quick View:

| Property | Unit | 5052 Alloy |

|---|---|---|

| Density | g/cm³ | 2.68 |

| Melting Point | °C | 605-650 |

| Thermal Conductivity | W/m-K | 138 |

| Modulus of Elasticity | GPa | 70 |

| Specific Heat Capacity | J/g·K | 0.9 |

This systematic characterization allows meticulous engineering decisions when integrating 5052 checkered plates and sheets into large-scale industrial or architectural projects.

https://www.al-alloy.com/a/5052-aluminum-checkered-plate-and-aluminum-sheet.html