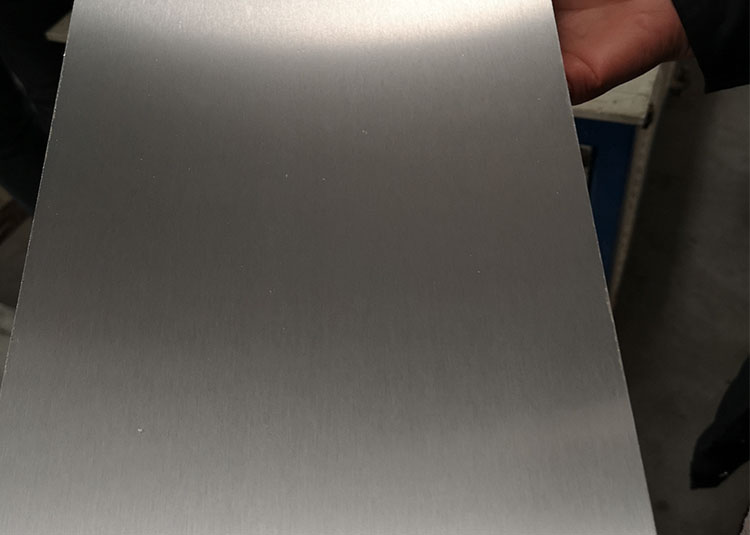

Aircraft aluminum plate

When we think of airplanes, our minds often jump to sleek designs, powerful engines, or cutting-edge avionics. Yet, beneath the dazzling exterior and sophisticated technology lies a fundamental material whose role is truly indispensable: the aircraft aluminum plate.

Why Aluminum? The Balance Between Strength and Lightness

In aviation, every pound counts. Excess weight literally translates to higher fuel consumption and reduced payload capacity. This is where aluminum alloys find their starring role. Aluminum plates used in aircraft are engineered not just for lightness, but for a precise balance of strength, corrosion resistance, and fatigue performance — all qualities critical for the harsh environment of high-altitude flight.

Decoding Aircraft Aluminum Plate Grades and Tempers

Not all aluminum is created equal. The aerospace industry relies predominantly on high-strength aluminum alloys such as the 2000 and 7000 series, classified by standards like AMS (Aerospace Material Specifications) and AMS 4037 (for aluminum sheets and plates). A typical example is the 7075-T6 aluminum plate, renowned for its exceptional tensile strength, often exceeding 500 MPa, rivaling many steels but at roughly one-third the weight.

Here is a quick glance at alloys and their characteristics:

| Alloy | Chemical Composition (approx. %) | Typical Strength (MPa) | Common Temper | Usage |

|---|---|---|---|---|

| 2024-T3 | Al 93.5, Cu 4.4, Mg 1.5, Mn 0.6 | 450 | T3 | Wing skins, fuselage frames |

| 6061-T6 | Al 97.9, Mg 1.0, Si 0.6 | 310 | T6 | Structural components |

| 7075-T6 | Al 87.1, Zn 5.6, Mg 2.5, Cu 1.6 | 572 | T6 | Highly stressed parts |

Many aerospace plates undergo specific heat treatments that alter their microstructure and hardness—the temper in "T6," "T3," or "O" denotes these treatments. For instance, T6 temper means solution heat-treated and artificially aged, facilitating a fine-grained microstructure that boosts strength without becoming too brittle.

The Art of Fabrication and Standards Ensuring Safety

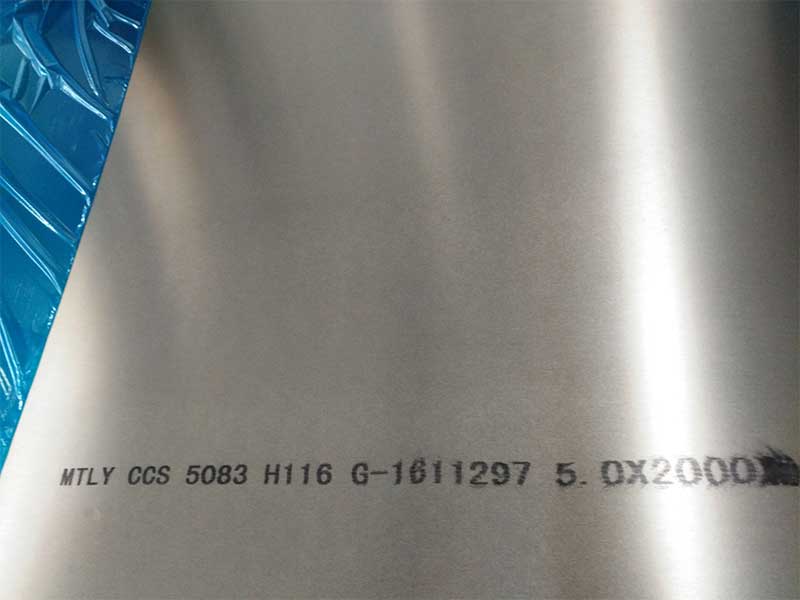

Aircraft aluminum plates need more than just tight chemical specs. Standards — such as AMS4841 for plate manufacturing or ASTM B209 — govern thickness tolerances (often ±0.127 mm), surface finish quality, and homogeneity to ensure repeatable performance.

Additionally, aerospace engineers continuously test for properties like:

- Tensile strength and yield strength

- Elongation percentage (ductility)

- Fatigue life under cyclic loading

- Corrosion resistance in salt spray or varied climates

- Crack propagation resistance

These parameters are critical because parts made from these plates often face dynamic stresses and environmental exposures during flight cycles.

A Unique Perspective: Aircraft Aluminum Plate as a ‘Living Skin’

Looking beyond raw materials, envision the aircraft aluminum plate as a "living skin" — flexible yet strong, capable of sustaining millions of stresses that come with takeoff, turbulence, temperature extremes, and landing. This skin must be resilient against fatigue cracks, deformation, and corrosion, much like biological skin adapts and repairs itself after minor trauma.

Engineers sometimes enhance this "skin" by treating aluminum plates with anodizing processes or adhering composite covers, to further improve corrosion resistance and reduce radar signature — a concept used in military aviation.

Environmental and Future Considerations

With sustainability a growing demand, the recycling of aluminum alloy plates is an important advantage — reducing energy consumption by up to 95% compared to primary production. Efforts are ongoing to develop advanced aluminum-lithium alloys or hybrid plates combined with composite materials to push aerospace efficiencies further.

The modest aircraft aluminum plate, often considered a mere construction element, is in truth the backbone of aviation safety and efficiency. From alloy selection, precision tempering, rigorous standards adherence to innovative treatments, these plates symbolize aviation’s extraordinary marriage of material science and engineering designed to keep us soaring safely above the clouds.

References & Standards:

- AMS 4037: Aluminum alloy sheet, rolled and clad, for aircraft structure

- AMS 4841: Aluminum alloy plate, rolled and clad, for aircraft structure

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- “Aluminum Alloys: Structure and Properties”, Davis, 1993

If you’re an aerospace professional or enthusiast, next time you look at a jet streaking through the sky, think about the specially forged plates of aluminum holding that aircraft’s “living skin” together with invisible strength and precision technology.