6.5 mic embossed aluminum foil

6.5 mic embossed aluminum foil is a versatile product widely utilized across various industries due to its exceptional properties and unique features.

What is 6.5 Mic Embossed Aluminum Foil?

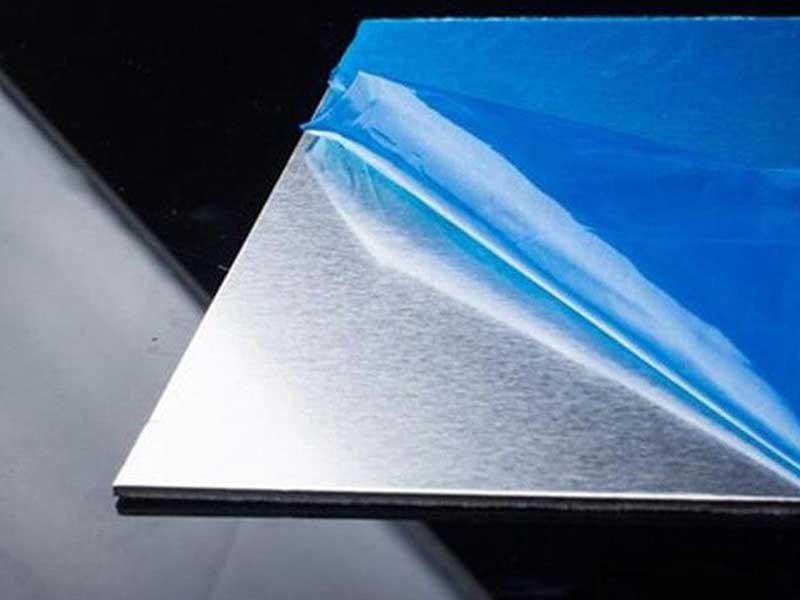

Embossed aluminum foil is characterized by its textured surface, which enhances specific functional attributes. The thickness of 6.5 micrometers (mic) makes it a suitable option for applications demanding lightweight yet durable materials. This foil is produced through a rolling process, followed by embossing to create unique patterns or textures that improve anti-slip properties, aesthetics, or other functionalities.

Features & Functions

The embossed surface offers several advantages:

- Enhanced Slip Resistance: Ideal for packaging or containers that may be handled frequently.

- Moisture & Sealability: Excellent impermeability against moisture, flavor, and odor, making it favorable for food packaging.

- Visual Appeal: Aesthetically pleasing texture that can enhance product presentation.

- Heat Reflectivity: Effective in thermal applications where temperature control is crucial.

Applications of 6.5 Mic Embossed Aluminum Foil

The versatility of 6.5 mic embossed aluminum foil facilitates its use across different industries, as highlighted in the following table:

| Industry | Application |

|---|---|

| Food Packaging | Wrapping, baking trays, and take-out containers. |

| Pharmaceuticals | Packaging pills, tablets, and medical supplies. |

| Construction | Insulation foil, light fittings, and heating systems. |

| Automotive | Component protection, decorative strips, and insulation. |

| Consumer Goods | Gift wrapping and product labeling. |

Technical Specifications

the technical aspects of 6.5 mic embossed aluminum foil is essential for selecting the right product. Below is a breakdown of the specifications and performance measures in table format.

| Parameter | Details (Metric) |

|---|---|

| Thickness | 6.5 micrometer (μm) |

| Width | Customizable, commonly 200mm to 1000mm |

| Alloy Type | 1050, 1060, or 1100 |

| Temper Condition | H14, H16 (O, H) standard depending on application |

| Yield Strength | 70-130 MPa |

| Elongation | Varies depending on temper (6-10%) |

| Electrical Conductivity | 35% IACS |

| Thermal Conductivity | 235 W/m·K |

| Density | 2.70 g/cm³ |

Chemical Composition

The performance of the aluminum foil is significantly impacted by its chemical composition. Below is the elemental composition of common alloy classifications.

| Aluminum Alloy | Elements | Composition (%) |

|---|---|---|

| 1050 | Aluminum | 99.5 min |

| Iron | 0.05 max | |

| Copper | 0.05 max | |

| Manganese | 0.05 max | |

| Zinc | 0.1 max | |

| 1060 | Aluminum | 99.6 min |

| Iron | 0.1 max | |

| Copper | 0.05 max | |

| 1100 | Aluminum | 99.0 min |

| Copper | 0.05-0.2 | |

| Iron | 0.1 max |

Implementation Standards

The production and quality standards adhered to in the supply of embossed aluminum foil typically follow detailed industry guidelines. Here are common standards to which producers and vendors align:

| Standard | Description |

|---|---|

| ISO 9001 | Quality Management System |

| ASTM B226 | Standards for Aluminum Foil |

| FDA Regulations | Safety aspects in food contact material |

https://www.al-alloy.com/a/65-mic-embossed-aluminum-foil.html