Decorative aluminum sheet metal

Aluminum sheet metal often brings to mind thoughts of construction materials or industrial usage. However, its decorative variant—decorative aluminum sheet metal—delves into an enticing realm of design that combines aesthetics with functionality.

Defining Decorative Aluminum Sheet Metal

Decorative aluminum sheet metal refers to aluminum plates that have been enhanced with various surface treatments, finishes, textures, or finishes to create an eye-catching appearance, elevating not just the functionality but also the aesthetic appeal of various applications. These sheets maintain the lightweight, corrosion-resistant, and malleable attributes of basic aluminum while infusing style into spaces and structures.

Functions and Applications

1. Architectural Designs

Facade Cladding: Decorative aluminum sheets create stunning exteriors in commercial skyscrapers and residences. Various designs, such as perforated patterns or intricate motifs, breathe life into buildings. A reflective surface can dramatically enhance lighting and reduce energy consumption by reflecting sunlight away from the structure.

Interior Decoration: Within interior spaces—be it kitchens, conference rooms, or galleries—decorative aluminum sheet metal serves as wall paneling, bringing an angular allure to interiors and giving depth to otherwise simplistic designs.

2. Signage

Decorative aluminum is highly sought in industries for signs, displaying brand logos, or directions and warnings. Its weather-resistant properties and inherent load-bearing capability assure longevity even under the harshest outdoor conditions.

3. Home Furnishings

From kitchen cabinets adorned with aluminum decoration to tabletops featuring patterned aluminum sheets, the construction moves beyond mere industrial application, granting consumers the elegance and sophistication they seek in home decor.

4. Automotive Applications

Aluminum sheets have gained more notice in the automotive industry, converging technical performance with aesthetic value. Custom panels abroad cars serve to enhance visual appeal while reducing overall vehicle weight, crucial for fuel efficiency.

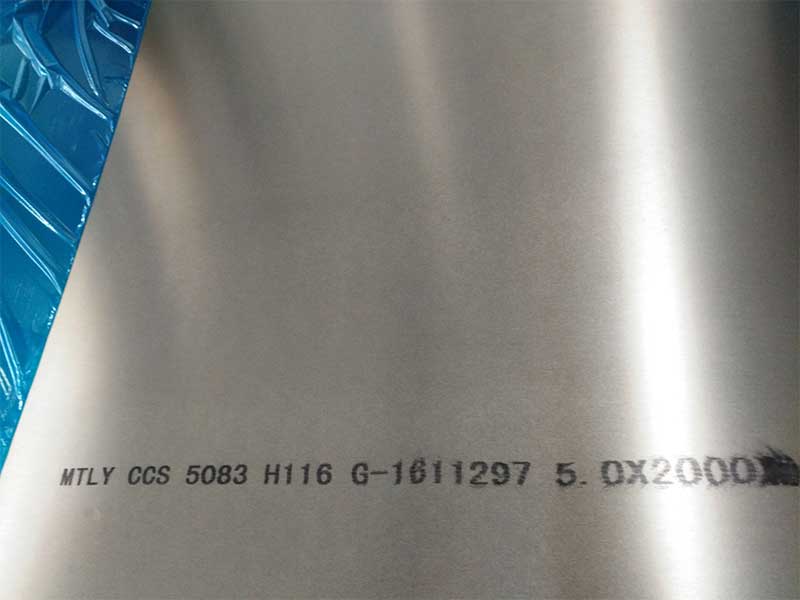

Technical Parameters of Decorative Aluminum Sheets

| Property | Value/Standard |

|---|---|

| Thickness range | 0.2mm to 6.0mm |

| Width limitation | 100mm to 2000mm |

| Length restriction | Custom lengths available |

| Finish type | Anodized, painted, recycled patterns, or textured surface options |

| Alloy Types | 1000 Series to 5000 Series (Aluminum 1100, 3003, 5052, etc.) |

| Tempering conditions | T3 (solution heat treated), T4 (solution heat treated and artificially aged), T6 (solution heat treated and artificially aged) |

| Corrosion Resistance | Excellent on anodized surfaces |

| Typical Uses | Excellent machinability and formability |

| Chemical composition (in terms of weight percentage) | |

| Aluminum | Above 90% |

| Copper | ≤ 0.1% |

| Manganese | ≤ 1.5% |

| Magnesium | ≤ 5.0% |

| Silicon | ≤ 0.5% |

Alloy Tempering and Performance Criteria

the importance of alloy tempering in decorative aluminum sheets aids in navigating their extensive application potential. Orbital specifications designate aluminum sheets using series grades—from the soft, ductile characteristics of series 1000, primarily comprising pure aluminum, to stronger 5000 series, often utilized in marine applications due to its superior corrosion resistance.

Temper T3 refers to treated sheets tendered to a solution heat and then naturally aged, making them applicants for elaborate designs without losing flexibility.

Temper T6 exemplifies aluminum sheets that fortify strength while maintaining optimum durability and resistance properties through artificial aging.

The invulnerable integration of chemical properties allows designers and architects accessibility to a palette that transcends traditional stigma of sheet metal—extending reach through synergistic undertakings across arts and architecture.

Implementation Standards

Compliance with various industry standards is paramount for ensuring material reliability and structural integrity. The following organizations play a role in setting standards for design references and fabrication protocols for aluminum sheets:

ASTM (American Society for Testing and Materials) outlines precise physical and technical information for many species of aluminum, establishing how they must perform in practical application.

ISO 9001 Quality Management Standard delineates an assurance of systemic quality measures in processes associated with aluminum sheet metal production.

these standards enables users to tap not only into contemporary demands but transcends them by fostering innovative layouts without compromising security.

https://www.al-alloy.com/a/decorative-aluminum-sheet-metal.html